Photos of homemade ice lamps. Do-it-yourself powerful LED lamp - development, installation. Features and stages of installation work

For any work, as well as during rest, you need good light. You can buy a lamp, but sometimes it is not cheap. In the store, instead of a ready-made lamp, you can purchase an LED strip. It is relatively inexpensive and can be cut into pieces of any length. If you place it in the housing or secure it in another way, you will get a homemade lamp with an LED strip. You can take this lamp with you to your tent when fishing. When traveling, the LED lamp is connected to a car battery.

Scope of application of homemade LED lamps

Homemade LED lamps for LED strip can be used instead of conventional ones:

- illumination of the workplace when performing small work in a workshop or garage;

- illumination from above the aquarium (if the tape is waterproof or in a sealed housing, then the lamp can be lowered into the water);

- illumination of seedlings or indoor plants in winter;

- night light or table lamp;

- lighting of switches and sockets;

- computer keyboard lighting;

- for replacing fluorescent lamps.

On the Internet you can find many other types of floor lamps and ceiling chandeliers made from LED strips with photos and videos, as well as reviews from people who collected and used such lamps.

Types and parameters of LED strips

LED strip color optionsLED strips are available in different designs depending on the type of protection. They can be of different brightness and different colors, which are determined by color temperature - from warm white (2700K) to cold (6800K), as well as colored or capable of changing their color - RGB tapes. This makes it possible to select the type of device for specific purposes.

LED strip device

An LED strip is a flexible plastic strip with conductive strips printed on it. Two are located at the edges and connections are made to them. The rest connect LEDs and resistors to each other. They are arranged in groups - three LEDs connected in series, and a resistor that serves to limit the current flowing through them.

LED strip parameters

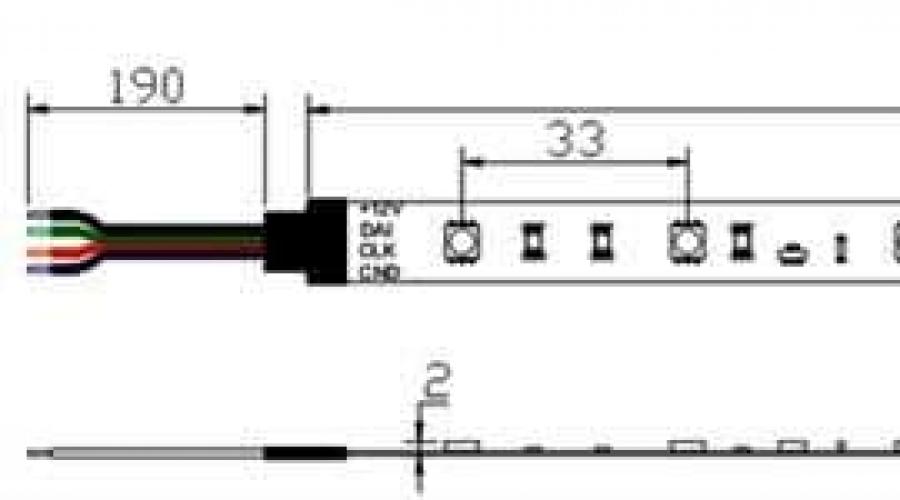

LED strip parameters The strip itself can be cut into sections that are multiples of three LEDs. In these places there are marks indicating the place of the cut and the contact pads to which the wires are soldered or connected using connectors.

LEDs can be coated with a layer of silicone on one or both sides. This determines the degree of protection from external influences. On the reverse side, an adhesive layer is applied to the strip, like on double-sided tape. With its help, the LEDs are attached to the base.

The most common supply voltage is constant, 12V. There are designs designed to connect to a voltage of 24V and higher, but these are not very common designs.

Types of LEDs used

LEDs and resistors in the strip are used in the SMD series, without leads. LEDs in production are used in different sizes, which determines the marking of the strip - 5050 and 3528. These numbers show the size of the LED in tenths of a millimeter

Visual difference between 5050 and 3528

Visual difference between 5050 and 3528

Expert opinion

Alexey Bartosh

Ask a question to an expertThe larger the size, the higher the brightness and the current and power consumption. It also depends on the number of LEDs per meter of length.

Accordingly, marking an SMD 5050 strip with a density of 60 LEDs means that 60 SMD 5050 LEDs are installed per meter of length.

Controllers, power supplies for LED strips

controller and power supply

controller and power supply Since the LED strip is designed for a constant voltage of 12V, a power supply or controller is required for connection.

Important! When you connect the LED strip to a 220 volt network, it will instantly burn out!

Power supplies are produced in different capacities and shapes. From low-power ones, similar to tablet chargers, to powerful designs in a metal case with built-in coolers.

LED strip power supply power

LED strip power supply power Some power supplies are equipped with dimmers and remote controls. RGB strips require an RGB controller to control color.

There are models with control via WiFi, with color and music effects, for example, ARILUX® AL-LC01.

If you don’t have a special block available, you can use:

- Any transformer with an output voltage of 12V. A diode bridge and a smoothing capacitor must be connected to the output.

- The computer power supply, both in the computer itself and separately.

- If you need 3-6 LEDs, then you can use a capacitor to limit the current, as well as a diode bridge and a capacitor that smoothes out the pulsations of the glow. This scheme is used in LED lamps installed instead of incandescent lamps. The capacitance of the capacitor can be calculated using an online calculator.

- Make an energy-saving lamp out of the board of a faulty lamp.

- Connect 20 pieces of LED strip in series and connect through a diode bridge and a smoothing capacitor to a 220V network.

Preparation of materials and parts

making a lamp with your own hands

making a lamp with your own hands Before starting work, you need to determine the required number and brightness of the LED strip, as well as the power of the power supply.

First of all, you need to determine the length. For lamps used in different places you need:

- night light and illumination of switches and sockets - a segment of three LEDs;

- aquarium lighting – along the length of the wall;

- illumination of a bed with seedlings - several pieces, a length equal to the length of the beds;

- computer keyboard – along the length of the keyboard;

- To replace a fluorescent lamp, you need several pieces, equal in length to the length of the lamp.

The brightness of the strip, the size and density of the LEDs are determined based on specific conditions.

The power of the power supply should be no less than the power of the LED lamp, and preferably 20% more. This is necessary for more reliable operation of the unit.

In addition, you will need wires, heat shrink tubing to insulate the connection point, a soldering iron with tin and rosin, or a connector for connection.

Expert opinion

Alexey Bartosh

Specialist in repair and maintenance of electrical equipment and industrial electronics.

Ask a question to an expertAttention! You cannot solder the tape with acid! Acid fumes oxidize and destroy wires and can also cause short circuits.

If the lamp will be used in an aquarium for internal lighting, then you will need a transparent tube and silicone sealant to ensure the tightness of the structure.

Lamp assembly

LED lamp assembly

LED lamp assembly After developing the design of the future lamp and preparing all the tools and materials, the lamp itself is assembled.

Sometimes the entire assembly process involves applying tape to a base, such as a backlit keyboard that sits on a pull-out shelf under a desk.

In other cases, it is necessary to manufacture or remodel an existing lamp.

Features and stages of installation work

Installation and connection of a lamp made from LED strip has a number of features:

- The power supply should be located as close to the LEDs as possible. The longer the wires, the greater the voltage loss in them, which leads to a loss of brightness of the lamp.

- It is advisable to isolate the LEDs from the base if it is metal.

- When connecting the device directly from a 220V network (via a capacitor), use only a tape coated with silicone on both sides.

Carefully! There is high voltage on such a tape, so all manipulations with it are carried out in the off state.

What to do if there is no ready-made LED strip

If you don’t have a ready-made LED strip, you can make it yourself.

To do this, the required number of LEDs must be connected in series and a current-limiting resistor connected to them. You can assemble such a structure on a strip of getinax or textolite, where holes are drilled for mounting LEDs. Such a device can be assembled for any required voltage and number of LEDs.

A 13.5 W LED bulb should have been sufficient to sufficiently illuminate a room of 8 m2. But in reality it turned out that there was not enough light.

The analysis showed that the reason for insufficient illumination with sufficient lamp power lay in the design of the LED lamp. In its lower part, parallel to the horizon and directed downwards, there were only 36 LEDs, and from the remaining 162 the light flux went to the sides and, in addition, decreased, passing through the frosted glass of the lampshade. Thus, the actual illumination of the floor was equivalent to illumination by an LED directional light bulb with a power of no more than three watts.

Due to the wrong choice of the type of light bulb, insufficient illumination in the kitchen, especially in winter, created discomfort, and the realization came that it was time to replace the light bulb in the chandelier with an LED lamp of a different design.

The search for an inexpensive LED bulb with a power of about 16-18 W with a wide angle of directional warm light was not successful. Due to the installed optics, lamps with powerful one-watt LEDs had a small angle or the base did not fit. And suitable lamps were very expensive. Lamps with low-power LEDs such as LED-Y-SMD352 or LED-Y-SMD5050 were not satisfactory in terms of power.

Since the existing lamp had a large shade, the idea arose to make a powerful LED lamp with your own hands from several low-power ones. As a result, four inexpensive MR16 lamps with a power of 4.5 W were purchased, four sockets with a GU5.3 base were purchased for them, and one powerful lamp was made from them, the glow of which you see in the photo.

The cost was less than $10, and the conversion took several hours. The result was excellent. True, the lamp began to look unusual, as if the past and high-tech were combined. A high-power LED lamp made from several low-power ones has an additional advantage - if one of them burns out, the room will continue to be sufficiently illuminated by the remaining light bulbs; you can easily change the shade of light by installing, for example, two warm light bulbs and two cold light bulbs.

Making a powerful LED lamp

Any work on making homemade products begins with sketch work - measuring the dimensions of parts and, taking into account their overall and connecting dimensions, drawing up a general sketch of the future product.

To make a composite one high-power LED lamp from several low-power ones, you will need a base for an E27 socket with a base from an energy-saving lamp, four MR16 lamps and four GU5.3 sockets for them. You can see their overall and connecting dimensions in the photographs of the sketches.

Next, based on the obtained dimensions of the parts, you need to draw a sketch of the base of the future lamp. A fiberglass plate with a thickness of 1.5 mm and a diameter of 90 mm was chosen as the base. The base can also be made of any metal, for example, aluminum or steel 1 mm thick.

The next step is marking the future base of the lamp. Using a caliper or school compass, a forming line of the base is drawn. Next, in accordance with the sketch, drilling points for holes for sockets for light bulbs and wires are drawn. The base can be given a round shape using an electric or manual jigsaw. The base can also be made into a rectangular shape by cutting it out using metal scissors. After sawing or cutting, sharp edges should be removed using fine sandpaper.

To obtain holes in precisely marked places, it is better to first drill them with a thin drill, for example with a diameter of 1 mm, and then drill them to the desired diameter with a thicker drill.

It was decided to secure the GU5.3 sockets to the base using screws with metric M3 threads. Therefore, holes with a diameter of 2.5 mm were first drilled, and then the threads were cut using a tap.

The holes through which the electrical wires will pass were removed with a larger diameter drill and the sharp edges were removed and chamfered.

The base for the homemade lamp is ready and you can start installing parts on it. To give the base an aesthetic appearance, you can paint it or cover it with film.

The easiest way is to cover the base with self-adhesive aluminum foil. I didn’t have a strip wide enough, and that’s why I ended up with a seam. If you don’t have foil covered with a sticky layer, you can use glue, for example, “Moment,” to glue ordinary aluminum foil, which is used for household needs, or a chocolate bar wrapper.

The socket from the base of the E27 energy-saving lamp is attached to the base using two corners with metric screws, bent at right angles from strips that clamp the power cable in Soviet-style C1-b electrical plugs. Corners can be made by cutting strips of steel sheet 1-2 mm thick, and use self-tapping screws as fasteners.

To ensure that the base of the energy-saving lamp does not spoil the insulation of the wires coming from the GU5.3 sockets, samples were made on four sides using a round file.

The first to be installed and secured onto the base of the future composite lamp are the GU5.3 electric sockets. The wires coming out of the sockets were quite long. I did not shorten them, since there was enough space for laying the wires in the base from the energy-saving lamp.

Next, one wire coming from each cartridge is twisted together. The remaining four wires from the cartridges are also twisted together. The resulting twists are soldered using a soldering iron with tin-lead solder. If soldering is not possible, the connection can be made using a terminal block.

It remains to lay out the wires in a spiral and connect their ends with the ends of the wires connected to the base of the energy-saving lamp. The color marking of the wires does not matter in this case.

The twisted wires coming from the sockets and the base are placed coaxially overlapping each other and secured with a drop of solder. A piece of vinyl chloride tube is put on the place of soldering for insulation.

All that remains is to thread the wires into the base of the energy-saving lamp and secure it to the base of the lamp with two screws. The new composite lamp is ready and you can screw it into the lamp socket and install LED bulbs into GU5.3 sockets.

Tests have shown that the LED light bulbs in the sockets are held with a sufficient layer. But the possibility of them falling out still existed. Therefore, to securely fasten them, a threaded stand was additionally installed in the center of the base.

After installing the LED bulbs, a large washer was secured to the stand using an M3 screw, which pressed the bulbs by the edges to the sockets and prevented them from spontaneously slipping out over time. Instead of a washer, you can attach, for example, frosted glass to a stand to obtain softer light or a decorative decoration.

The photo shows a self-made high-power LED light bulb made from four low-power ones. The photo of the lamp was taken from the base side. The lamp somehow reminds me of a modern spacecraft.

And this photo shows the view of a homemade lamp made from four low-power MR16s from their installation side.

Everyone who knew me saw a lamp with a modernized lamp was surprised at the wonder and noted the excellent illumination that the light bulbs provided in the kitchen. Although, when coming up with this design, I had a good idea of what would ultimately turn out, but the result exceeded all my expectations. It turned out much more interesting.

The proposed technology for manufacturing an LED lamp can be used to manufacture an adapter in order to be able to install a light bulb in a lamp with a type of base different from the type of lamp socket.

Good afternoon everyone, in this article I will continue the topic of LED lamps, and most importantly powerful ones, which means from 10 to 50 W. After a long search for my LEDs, I found 34 pieces of 1 W each. The question immediately arose: how to feed all this? A solution was found to use a TASHIBRA 50-60W electronic transformer. Our lamp consumes a fair amount and it should start without modification. I added a diode bridge (the diode bridge must be high-frequency or mid-frequency) and a capacitor. Yes, that's a simple trick. But I must warn you: such a power supply does not have any stabilization or protection. To extend the life of LEDs, you do not need to power them with 12 volts, as expected, but 10-11 V, which is quite enough and the brightness does not drop, there is a small reserve for increasing the voltage in the network. Also, we cannot avoid the issue of filters at the input, you need to install a 400 Volt 10 uF capacitor and wind several turns of the network wire around the ferrite ring, that’s all.

All this came to me a little late and is not visible in the photo. Well, a sore subject, cooling of LEDs. How to provide good cooling, but so that all this is compact and without coolers. You know how in the fairy tale “There is a solution - you just need...” just now? - you ask. You need to reduce the LED supply voltage by 10-20% - that's all. Many will now say, but what if the brightness also drops? I can honestly tell you that the brightness will drop by no more than 5-10%. But you will extend the life of the LEDs, and at the same time reduce the generation of unnecessary heat.

We rewind the transformer, make a radiator from a piece of aluminum and attach the LEDs as follows: spread a little thermal paste on the seat, and then fix the LEDs to the radiator with epoxy resin. I fixed it with hot glue for testing, but this is not a solution. Next, we collect everything into a “heap”. After testing, it turned out that the radiator area was too small, after which I installed a small cooler, which solved all the problems.

Final testing showed that the radiator temperature is only 38 degrees after 4 years of operation. When comparing an ordinary incandescent lamp and a new one, the result, as they say, is obvious. Thank you all for your attention, Kalyan-Super-Boss was with you. Good luck repeating the pattern!

Gradually, lighting devices are switching to LED lamps. This did not happen immediately; there was a protracted transition period with the use of so-called housekeepers - compact gas-discharge light bulbs with a built-in power supply (driver) and a standard E27 or E14 socket.

Such lamps are still widely used today, since their cost in comparison with LED light sources is not so “biting”.

While there is a good balance between price and efficiency (the difference in price with conventional incandescent lamps pays off over time due to energy savings), gas-discharge light sources have a number of disadvantages:

- Service life is lower than that of incandescent lamps.

- High frequency noise from the power supply.

- Lamps do not like frequent switching on and off.

- Gradual decrease in brightness.

- Impact on nearby surfaces: a dark spot appears on the surface of the ceiling (above the lamp) over time.

- And in general, I don’t really want to have a flask with a certain amount of mercury in my house.

An excellent alternative is LED lamps. The list of advantages is significant: - Amazing efficiency (up to 10 times compared to incandescent lamps).

- Huge service life.

- Perfect and safe power supplies (drivers).

- Absolutely independent of the number of inclusions.

- With normal cooling, they do not lose brightness for almost the entire period of operation.

- Complete mechanical safety (even if the decorative diffuser is broken, no harmful substances will enter the room).

- The direction of the light flux places high demands on the design of the diffuser.

- Still, they are expensive (we are talking about quality brands, nameless mid-level products are quite affordable).

But it is precisely in this design that the “ambush” lies.

We have before us a high-quality (at the same time relatively inexpensive) lamp with a brightness of 1000 Lm (equivalent to a 100-watt incandescent lamp) and a power consumption of 13 W. These LED light sources have been working for me for many years, they shine with a pleasant warm light (temperature 2700 K), and no degradation of brightness is observed over time.

But for powerful light, serious cooling is required. Therefore, 2/3 of the body of this lamp consists of a radiator. It is plastic, does not spoil the appearance, and is quite effective. The main drawback follows from the design - the real light source is the hemisphere at the top of the lamp. This makes it difficult to select a lamp - not every horn chandelier will have such a lamp look harmonious.

There is only one way out - to buy ready-made LED lamps, the configuration of which was initially designed for specific light sources.

The key word is buy. What should you do with your favorite floor lamps, chandeliers and other lamps in your apartment?

Therefore, it was decided to design LED lamps ourselves.

The main criterion is cost minimization.There are two main directions in the development of LED light sources:

1. Use of low-power (up to 0.5 W) LEDs. You need a lot of them, you can configure any shape. No need for a powerful radiator (they heat up little). A significant drawback is more painstaking assembly.

2. Use of powerful (1 W - 5 W) LED elements. Efficiency is high, labor costs are several times less. But point radiation requires the selection of a diffuser, and good radiators are needed to implement the project.

For experimental designs, I chose the first option. The most inexpensive “raw materials”: 5 mm LEDs with a dispersion of 120° in a transparent housing. They are called "straw hats".

The characteristics are as follows:

- forward current = 20 mA (0.02 A)

- voltage drop across 1 diode = 3.2-3.4 volts

- color – warm white

I bought several packs 100 pcs. on aliexpress(link to purchase). It cost a little less than 1 rub. a piece.

As power supplies (more precisely, current sources), I decided to use a proven circuit with a quenching (ballast) capacitor. The advantages of such a driver are extreme low cost and minimal energy consumption. Since there is no PWM controller or linear current stabilizer, excess energy does not go into the atmosphere: in this circuit there are no elements with a heat-dissipating radiator.

Disadvantage: lack of current stabilization. That is, if the mains voltage is unstable, the brightness of the glow will change. My outlet has exactly 220 (+/- 2 volts), so this circuit is just right.

The element base is also not expensive.

- diode bridges of the KTs405A series (any diodes can be used, even Schottky ones)

- film capacitors with a voltage of 630 volts (with a reserve)

- 1-2 watt resistors

- electrolytic capacitors 47 mF at 400 volts (you can take a larger capacity, but this goes beyond the scope of economy)

- little things like a breadboard and fuses are usually in the arsenal of any radio amateur

After carefully (on the street!) removing the flask with mercury vapor, you are left with an excellent workpiece for creativity.

The basis of the basics is the calculation and principle of operation of a current driver with a quenching capacitor

A typical diagram is shown in the illustration:

How the scheme works:

Resistor R1 limits the current surge when power is applied until the circuit stabilizes (about 1 second). Value from 50 to 150 Ohm. Power 2 W.Resistor R2 ensures the operation of the ballast capacitor. Firstly, it discharges it when the power is turned off. At a minimum, to prevent you from being shocked when unscrewing the light bulb. The second task is to prevent a current surge in the case when the polarity of the charged capacitor and the first half-wave of 220 volts do not coincide.

Actually, the damping capacitor C1 is the basis of the circuit. It is a kind of current filter. By selecting the capacitance, you can set any current in the circuit. For our diodes it should not exceed 20 mA at peak mains voltage.

Next, the diode bridge works (after all, LEDs are elements with polarity).

Electrolytic capacitor C2 is needed to prevent the lamp from flickering. LEDs have no inertia when turned on and off. Therefore, the eye will see a flicker with a frequency of 50 Hz. By the way, cheap Chinese lamps are guilty of this. The quality of the capacitor is checked using any digital camera, even a smartphone. Looking at the burning diodes through a digital matrix, you can see blinking, indistinguishable to the human eye.

In addition, this electrolyte gives an unexpected bonus: the lamps do not turn off immediately, but with a noble slow attenuation until the capacity is discharged.

The quenching capacitor is calculated using the formula:

I = 200*C*(1.41*U network - U led)

I – resulting circuit current in amperes

200 is a constant (network frequency 50Hz * 4)

1.41 – constant

C – capacitance of capacitor C1 (quenching) in farads

U network - estimated network voltage (ideally 220 volts)

U led – total voltage drop across the LEDs (in our case – 3.3 volts, multiplied by the number of LED elements)

By selecting the number of LEDs (with a known voltage drop) and the capacity of the quenching capacitor, it is necessary to achieve the required current. It should not be higher than specified in the characteristics of the LEDs. It is the strength of the current that you regulate the brightness of the glow, and inversely proportional to the lifespan of the LEDs.

For convenience, you can create a formula in Excel.

The circuit has been tested several times, the first copy was assembled almost 3 years ago, it works in a kitchen lamp, there have been no malfunctions.

Let's move on to the practical implementation of projects. There is no point in discussing the number of LED elements and capacitor capacity in individual circuits: the projects are individual for each lamp. Calculated strictly according to the formula. The above circuit for 60 LEDs with a 68 microfarad capacitor is not just an example, but a real calculation for a current in the circuit of 15 mA (to extend the life of the lights).

LED lamp in a chandelier

We use the gutted cartridge from the housekeeper as a housing for the circuit and supporting structure. In this project I did not use a breadboard; I assembled the driver on a 1 mm thick PVC roundel. It turned out to be just the right size. Two capacitors - due to the selection of capacitance: the required number of microfarads was not found in one element.

A yogurt jar was used as a housing to house the LED elements. In the design I also used scraps of 3 mm foamed PVC sheets.

After assembly it turned out neat and even beautiful. This arrangement of the socket is associated with the shape of the chandelier: the horns are directed upward, towards the ceiling.

Next we place the LEDs: according to the scheme, 150 pcs. We pierce the plastic with an awl, labor costs: one full evening.

Looking ahead, I will say: the material of the case did not justify itself, it is too thin. The next lamp was made from 1 mm PVC sheet. To give it a shape, I calculated the scan of the cone using the same 150 diodes.

It turned out not so elegant, but reliable, and holds its shape perfectly. The lamp is completely hidden in the chandelier arm, so appearance is not so important.

Actually, installation.

It shines evenly and doesn’t hurt your eyes.

I didn’t measure the lumens, but it felt brighter than a 40 W incandescent lamp, a little weaker than 60 W.

LED lamp in a flat ceiling lamp for the kitchen

An ideal donor for such a project. All LEDs will be located in the same plane.

We draw a template and cut out a matrix to accommodate the LED elements. With this diameter, a flat PVC sheet will be deformed. So I used the bottom of a plastic bucket of construction mixtures. There is a stiffening rib along the outer contour.

The diodes are installed using the usual awl: 2 holes according to the markings.

In this article we will look at examples of making homemade LED lamps for various needs.

1. The simplest lamp for household needs.

First, you need to decide which LEDs are best to use. If you choose between powerful and low-power ones, the former are better in terms of labor intensity. To replace one powerful 1 W LED, you will need 15-20 low-power 5 mm or SMD LEDs. Accordingly, soldering with low-power ones is much greater. Let's focus on the powerful ones. They are usually divided into two types - lead-out and surface-mount. To make life easier, it is better to use output ones. It is better to choose LED power no more than 1 W.

We will also need a current driver so that the LEDs receive the necessary voltage and last a long time.

In addition, for long-term operation of an LED (especially a powerful one), a radiator is required. Aluminum is best suited for its manufacture. For each one-watt LED you need a piece of aluminum 50x50 mm, about 1 mm thick. The piece may be smaller if it is bent. If you take a piece of 25x25 mm and a thickness of 5 mm, you will not get the desired effect. To dissipate heat, you need area, not thickness.

Let's consider a model of the simplest lamp. We will need: three 1 W LEDs, a 3x1 W driver, double-sided heat-conducting tape, a radiator (for example, a piece of U-shaped profile 1 mm thick and 6-8 cm long).

Thermal tape can conduct heat. Therefore, ordinary double-sided tape will not work. Cut a strip of tape 6-7 mm wide.

We degrease the radiator and the bottoms of the LEDs. It is not advisable to use acetone for this - the plastic lens of the LED may become cloudy.

Place tape on the radiator. Then we mark the radiator to install the LEDs evenly.

We install the LEDs on the tape. At the same time, we observe polarity - all LEDs must be rotated equally so that the “plus” of one LED faces the “minus” of the neighboring one. Lightly press them for better contact. After this, we apply tin to the leads of the LEDs to facilitate further soldering. If you are concerned that the tape may burn out, simply lift the leads of the LEDs so that they do not touch the tape. At the same time, you need to hold the LED housing with your finger so that it does not come off the tape. However, you can bend the conclusions in advance.

We connect the LEDs to each other. For this, a core from any stranded wire is quite sufficient.

Solder the driver.

The simplest model of the lamp is ready. Now you can insert it into any suitable housing. Of course, you can make a more powerful lamp, you just need more diodes and a more powerful driver, but the principle will remain the same. This technique is suitable for both the manufacture of a single lamp and small-scale production.

2. Chandelier based on LEDs.

We will need:

1. Base from a burnt-out energy-saving lamp.

2. Two grips (to connect to the LED);

3. Powerful ten-watt LED, color of your choice;

4. Two small screws;

5. One ten watt LED driver;

6. Thermal paste;

7. Radiator;

8. Heat shrink tube (or insulating tape);

9. wires with a cross section of 2 mm.

First you need to disassemble the old or burnt-out energy-saving lamp. It is important to be careful not to damage the glass flask. Otherwise, mercury gas, which is very harmful to health, will come out of it.

We only need the part of the case with the base. Let's cut off the leads from the board going to the base and solder our own leads coming from the LED driver, insulating them with heat-shrinkable tubes.

Using a soldering iron, we will make a couple of holes for the wire, which will hold the entire structure.

Next, we use the terminals, crimp them, and connect them to the LED, observing the polarity. Let's check. It is not recommended to look at the LED when it is on. The light intensity is very strong and may harm your eyes. If everything works, we assemble the lamp into a single whole.

The LED is very bright and casts harsh shadows. You can make the light smoother and softer by using a homemade diffuser. Many different materials can be used as a diffuser. The simplest one is to cut out the bottom of a two-liter plastic bottle and sand it on all sides to make it completely opaque to direct light. We make four holes and attach it to the radiator with wire.

3. Home LED lamp.

As a light source we use Cree MX6 Q5 LEDs with a power of 3 W and a light output of 278 lm. The LED will be placed on a 5x5 cm heatsink taken from the processor of an old motherboard.

For simplicity, we will use a pulse source together with an electronic adapter that will provide the necessary voltage and current to power the LEDs. For this purpose, in our case, we chose a non-working mobile phone charger that, according to the manufacturer, has an output voltage of 5 V and a current of 420 mA.

To protect from external influences, the entire electronic part will be placed in a socket from an old lamp.

According to the manufacturer's instructions, the Cree MX6 Q5 LEDs can operate at a maximum current of 1 A at a voltage of 4.1 V. Logically, for normal operation, we will need a 1 ohm resistor to reduce the voltage by about one volt of the five that the charger provides , to get the required 4.1 V, and this is only if the charging produces a maximum current of 1 A. However, as it turned out later, a charger with a design limitation of a current of 0.6 A works without problems. Testing chargers for other mobile phones in the same way, it was found that they all have a current limit of 20-50% higher than that specified by the manufacturer. The meaning of this is that any manufacturer will strive to develop a power supply so that it does not overheat even if the powered device is damaged or short circuited, and the easiest way in this case is to limit the current.

Thus, we have a DC source limited to 0.6 A, powered by 230 V AC, factory made and small in size. However, during operation it only heats up slightly.

Let's move on to assembly. First, you need to open the power supply in order to remove the parts that will be inserted into the body of the new lamp. Since most power supplies are connected by soldering, we open the unit with a hacksaw.

In order to secure the board in the lamp body, in our case we used sanitary silicone. Silicone was chosen for its resistance to high temperatures.

Before closing the lamp, we attach the radiator to the cover (using bolts) to which the LED was attached.

The lamp is ready. The power consumption is just under 2.5 W, the luminous flux is 190 lm, which is ideal for an economical, long-lasting and durable table lamp.

4. Lamp in the corridor.

To illuminate the hallway with LED lights, we used two Cree MX6 Q5 LEDs, each of which has a power of 3 W and a light output of 278 lm and is powered by an old Samsung cell phone power supply. And although the manufacturer specified a current of 0.7 A in the specification, after measurements it was found that it is limited to 0.75 A.

The manufacturing scheme for the lamp base is similar to the previous version. The entire external structure is assembled using textile Velcro, glue and plastic washers from motherboards.

The total consumption of this design is about 6 W with a luminous flux of 460 lm.

5. Lamp in the bathroom.

For the bathroom, we used a Cree XM-L T6 LED powered by two LG phone chargers.

Each charger claims to produce 0.9A of current, but I found that the actual current is 1A. Both power supplies are connected in parallel to produce 2A of current.

With such indicators, the LED lamp will produce a luminous flux of 700 lm with a power consumption of 6 W.

6. Kitchen lamp.

If for the hallway and bathroom there was no need to provide a certain minimum of illumination, then this is not the case in the kitchen. Therefore, it was decided to use not one, but two series-connected Cree XM-L T6 LEDs for the kitchen, each of which has a maximum power consumption of 9 W and a maximum luminous flux of 910 lumens.

For effective cooling, in our case, we used a heatsink removed from Slot 1 of the Pentium 3 processor, to which both LEDs were attached using ArcticAlumina hot-melt adhesive. Although Cree XM-L T6 LEDs can consume a current of 3 A, the manufacturer recommends using a current of 2 A for reliable operation, at which they create a luminous flux of about 700 lm. A generating 12V at a current of 1.5A was used as a power source. After testing it with resistors, it was found that the current was limited to 1.8 A, which is very close to the desired value of 2 A.

To protect the heatsink and two LEDs, we used two plastic washers from the motherboard and two neodymium magnets taken from a damaged DVD drive, securing them with superglue and textile Velcro.

The LED light was expected to produce 1200 lumens, comparable to the 23W fluorescent bulb it was replacing, but it was discovered that the light emitted was actually even more intense, with a power consumption of around 12W - almost half that of the old bulb .

7. Office lamp

We will need:

1. LED strips 4 pcs (on powerful American CREE diodes)

2. Suitable driver (power supply) 1 pc.

3. Metal body of the future lamp.

4. Wiring, soldering iron, hand tools and fastening lamp.

You can use the body of an old lamp to make it

Or use a special aluminum profile with glass. In this case, the driver is installed inside the profile.

We install 4 diode strips.

We attach it to the ceiling (with cables) + install frosted glass.

Option of LED lamp in housing (from fluorescent 2x36W)

With glass

Or you can put everything in a 600x600 mm office lamp.

Well, as a bonus, let’s look at a few examples of decorative lamps based on LEDs.

For a decorative lamp we will need:

- 4 wooden planks of the same size;

- drill with 15 mm drill bit;

- wood glue;

- stain for wood;

- brush with pencil;

- sandpaper;

- LED candles.

First of all, you need to make several holes in each board with a drill, having previously made markings with a pencil - this way we will get a kind of pattern of circles.

Apply stain to wood.

Using glue, we connect 4 planks into a lamp.

We go over the lamp with sandpaper to give it a vintage look.

We place LED candles inside the lamp.

The night light is ready.

9. Lamp in oriental style.

We use cans of PVA glue as shades for lamps.

We will need:

- 2-3 cans of PVA glue

- cartridges, wire

- scissors, sharp knife

- hot glue gun

- bamboo napkins or straw ceiling tiles

First you need to cut the napkins into pieces of the required size.

On the base of the can, use a marker to circle a socket with a 1-watt LED and cut out a circle with a knife.

Then use a hot glue gun to glue the napkins to the jars.

Glue the tape to the empty spaces.

At this stage you can already see how it will glow.

All that remains is to decorate the braid at the joints with wooden beads.

For safety reasons, you need to drill holes for ventilation. You can have more, but they still won’t be visible.

That's all, the lamp is ready.

10. Unusual decorative lamp.

Making a lamp with your own hands began with drawing preliminary sketches on paper. There was a desire for the lamp not only to be curved in a plane, but also in space, and have a bizarre 3D wave shape.

After the sketch on paper is ready, we begin making the lamp. Each pipe in the drawing was measured, and the pipes were cut according to these dimensions. To obtain the required angles, templates were cut out of paper and attached with tape to the pipe.

All pipes were laid out on the table and adjustments were made to the waveform

The cuts were made on a stationary circular saw. This produces smooth, burr-free cuts with a width of 2 mm.

Now you need to connect all the pipes into one. The main task is to make smooth curves; for this it will not hurt to use a template (fibreboard sheet) on the table.

Since the pipes are cardboard, they can be connected using PVA glue, but I would recommend using glues that harden stronger and faster (moment, superglue).

On the reverse side, wooden planks were screwed onto self-tapping screws so that the homemade lamp could be hung on the wall. And holes were drilled in each pipe to output wires from the LED strips.

The pipes were painted with regular spray paint. The color red was used, since the wall on which the lamp was to be located was white, I wanted to get some contrast.

The paint dries very quickly, so you can begin installing the LEDs. The main thing to remember is that you can cut the LED strip only in specially marked places. The tape must be marked in advance so that it is enough for all 12 pipes.

We solder red wires to the “+” contact, and black wires to the “-” contact, so as not to confuse the polarity later.

We place the LED strips inside the pipes and fix them with the adhesive side to the pipe wall, and route the wires through pre-made holes. All that remains is to connect all the wires in parallel (connect red to red, and black to black) and connect to the power supply.

Now it's time to hang your homemade lamp on the wall.

The lamp is ready.