What to choose a two-pipe heating system. Installation of a two-pipe heating system. Roof and floors - meaning

Read also

Two-pipe heating system

There are only two types of heating systems: single-pipe and double-pipe. In private homes they try to establish the most effective system heating. It is very important not to go cheap when trying to reduce the cost of purchasing and installing a heating system. Providing heat to a home is a lot of work, and so as not to have to install the system again, it is better to understand it thoroughly and make “reasonable” savings. And in order to draw a conclusion about which system is better, it is necessary to understand the operating principle of each of them. Having studied the advantages and disadvantages of both systems, both with technical side So with the material, it becomes clear how to make the optimal choice.

Single pipe heating system

It works on the principle: through one main pipe (riser), the coolant rises to the top floor of the house (in the case multi-storey building); All heating devices are connected in series to the downward line. In this case, all upper floors will be heated more intensely than the lower ones. A well-common practice in Soviet-built multi-story buildings, when it is very hot on the upper floors and cold on the lower floors. Private houses most often have 2-3 floors, so single pipe heating does not threaten a large contrast in temperatures on different floors. In a one-story building, heating is almost uniform.Advantages of a single-pipe heating system: hydrodynamic stability, ease of design and installation, low cost of materials and funds, since the installation of only one coolant line is required. High blood pressure water will ensure normal natural circulation. The use of antifreeze increases the efficiency of the system. And although it's not best example heating system, it has become very widespread in our country due to the high savings in material.

Disadvantages of a single-pipe heating system: complex thermal and hydraulic calculations of the network;

- it is difficult to eliminate errors in the calculations of heating devices;

- interdependence of the operation of all network elements;

- high hydrodynamic resistance;

- limited number of heating devices on one riser;

- inability to regulate the flow of coolant into individual heating devices;

- high heat loss.

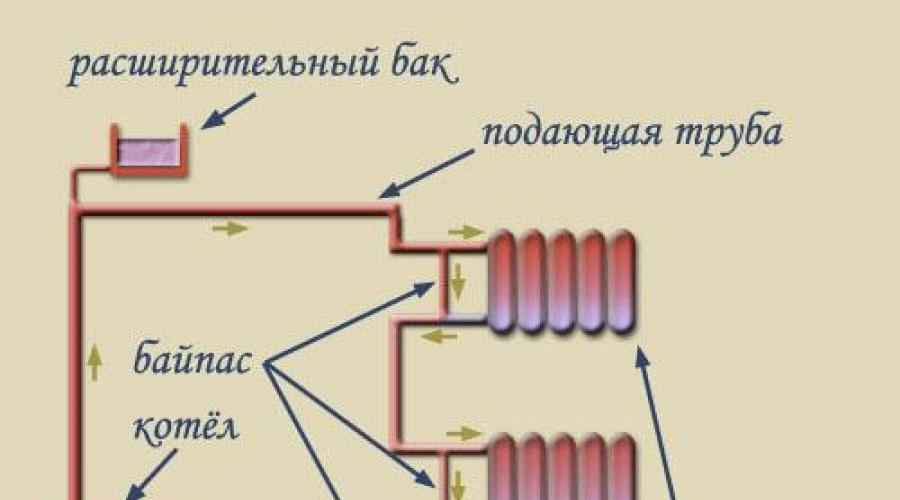

Improvement of single-pipe heating systems

A technical solution has been developed that allows you to regulate the operation of individual heating devices connected to one pipe. Special closing sections - bypasses - are connected to the network. The bypass is a jumper in the form of a piece of pipe that connects the direct pipe of the heating radiator and the return pipe. It is equipped with taps or valves. The bypass makes it possible to connect automatic thermostats to the radiator. This allows you to regulate the temperature of each battery and, if necessary, shut off the coolant supply to any individual heating device. Thanks to this, it is possible to repair and replace individual devices without completely shutting down the entire heating system. Correctly connecting the bypass makes it possible to redirect the flow of coolant through the riser, bypassing the element being replaced or repaired. For quality installation For such devices, it is better to invite a specialist.

Vertical and horizontal riser diagram

According to the installation scheme, single-pipe heating can be horizontal or vertical. A vertical riser is the connection of all heating devices in series from top to bottom. If the batteries are connected in series to each other throughout the entire floor, this is a horizontal riser. The disadvantage of both connections is air jams, occurring in heating radiators and pipes due to accumulated air.

The heating system with one main riser is equipped with heating devices with improved reliability characteristics. All devices of a one-pipe system are designed for high temperature and must withstand high pressure.

Installation technology of a single-pipe heating system

1. Installation of the boiler in the selected location. It is better to use the services of a specialist from service center, if the boiler is under warranty.

2. Installation of the main pipeline. If an improved system is being installed, then it is mandatory to install tees at the connection points of radiators and bypasses. For heating system with natural circulation when installing pipes

create a slope of 3 - 5o per meter of length, for a system with forced circulation coolant - 1 cm per meter of length.

3. Installation circulation pump. The circulation pump is designed for temperatures up to 60°C, so it is installed in that part of the system where the most low temperature, that is, at the entrance of the return pipe to the boiler. The pump operates from the mains power supply.

4. Installation expansion tank. An open expansion tank is installed at the highest point of the system, a closed one - often next to the boiler.

5. Installation of radiators. They mark out places for installing radiators and secure them with brackets. At the same time, they comply with the recommendations of device manufacturers regarding maintaining distances from walls, window sills, and floors.

6. The radiators are connected according to the chosen scheme, installing Mayevsky valves (for venting the radiators), shut-off valves, and plugs.

7. The system is pressure tested (air or water is supplied to the system under pressure to check the quality of connection of all elements of the system). Only after this, coolant is poured into the heating system and a test run of the system is performed, and adjustment elements are adjusted.

Two-pipe heating system

In a two-pipe heating system, the heated coolant circulates from the heater to the radiators and back. This system is distinguished by the presence of two pipeline branches. Along one branch, the hot coolant is transported and distributed, and along the second, the cooled liquid from the radiator is returned to the boiler.Two-pipe heating systems, like single-pipe heating systems, are divided into open and closed depending on the type of expansion tank. In modern two-pipe closed heating systems, membrane-type expansion tanks are used. The systems are officially recognized as the most environmentally friendly and safe.

According to the method of connecting elements in a two-pipe heating system, they are distinguished: vertical and horizontal systems.

In a vertical system all radiators are connected to a vertical riser. This system allows you to connect each floor separately to a riser in a multi-storey building. With this connection, there are no air pockets during operation. But the cost of this connection is slightly higher.

Double-pipe horizontal heating system is mainly used in one-story houses with large area. In this system heating devices connected to a horizontal pipeline. It is better to install risers for wiring connections of heating elements on staircase or in the corridor. Air jams are released using Mayevsky taps.

Horizontal heating system can be with bottom and top wiring. If the wiring is bottom, then the “hot” pipeline runs in the lower part of the building: under the floor, in the basement. In this case, the return line is laid even lower. To improve coolant circulation, the boiler is deepened so that all radiators are above it. The return line is located even lower. Upper overhead line, which must be included in the circuit, serves to remove air from the network. If the distribution is top, then the “hot” pipeline runs along the top of the building. The place for laying the pipeline is usually an insulated attic. At good insulation pipes, heat loss is minimal. At flat roof this design is unacceptable.

Advantages of a two-pipe heating system:

- even at the design stage, it is provided for the installation of automatic thermostats for heating radiators and, therefore, the ability to regulate the temperature in each room;

- pipes are routed throughout the premises in a special way collector system, which ensures the independence of the circuit devices;

- in other words, the circuit elements in a two-pipe system are connected in parallel, unlike a one-pipe system, where the connection is sequential;

- batteries can be inserted into this system even after assembling the main line, which is impossible with a single-pipe system;

- a two-pipe heating system can be easily extended in the vertical and horizontal directions (if you have to complete the house, then the heating system does not need to be changed).

For this system, there is no need to increase the number of sections in the radiators in order to increase the volume of coolants. Errors made at the design stage are easily eliminated. The system is less vulnerable to defrosting.

Disadvantages of a two-pipe heating system:

- more complex circuit connections;

- higher project price (much more pipes are required);

- more labor-intensive installation.

But these shortcomings are very well compensated by winter time when maximum heat accumulation occurs in the house.

Installation of a two-pipe heating system

I. Installation of a heating system with upper horizontal wiring

1. An angle fitting is mounted to the pipe leaving the boiler, which turns the pipe upward.

2. Using tees and angles, install the top line. Moreover, the tees are attached above the batteries.

3. When the top line is installed, the tees are connected to the top branch pipe of the battery, and a shut-off valve is installed at the junction point.

4. Then install the lower branch of the outlet pipeline. It goes around the perimeter of the house and collects all the pipes coming from the lowest point of the radiators. Typically this branch is mounted at the base level.

5. The free end of the outlet pipe is mounted into the receiving pipe of the boiler; if necessary, a circulation pump is installed in front of the inlet.

Mounted in a similar way closed system with constant pressure maintained injection pump, and an open heating system with an open expansion tank at its highest point.

The main inconvenience of a two-pipe heating system with overhead wiring is the installation of an expansion tank outside warm room on the ceiling. A heating system with overhead wiring also does not allow for the selection of hot water for technical needs, as well as for combining the expansion tank with the supply tank of the water supply system at home.

II. Installation of a heating system with lower horizontal piping

The bottom-piping system replaced the two-pipe heating system with top-piping. This made it possible to place the expansion tank open type in a warm room and easily accessible place. It also became possible to save some pipes by combining the expansion tank and the supply tank of the house water supply system. The compatibility of the two tanks eliminated the need to control the coolant level and made it possible, if necessary, to use hot water directly from the heating system.

In such a scheme, the outlet line remains at the same level, and the supply line is lowered to the level of the outlet line. This improves aesthetics and reduces pipe consumption. But it only works in systems with forced circulation.

Installation sequence:

1. Downward-facing corner fittings are installed on the boiler pipes.

2. At floor level, two lines of pipes are installed along the walls. One line is connected to the supply output of the boiler, and the second to the receiving output.

3. Tees are installed under each battery, connecting the batteries to the pipeline.

4. An expansion tank is installed at the top point of the supply pipe.

5. As in the case of the upper wiring, the free end of the outlet pipe is connected to the circulation pump, and the pump is connected to the inlet heating tank.

Maintenance of a two-pipe heating system

For high-quality maintenance of the heating system, it is necessary to implement a whole range of measures, including adjustment, balancing and tuning of the two-pipe heating system. To adjust and balance the system, special pipes are used, located at the highest and lowest points of the heat pipe. Air is released through the upper pipe, and water is supplied or drained through the lower pipe. Using special taps, excess air in the batteries is released. To regulate the pressure in the system, a special container is used, into which air is pumped using a conventional pump. Special regulators, reducing the pressure into a specific battery, adjust the two-pipe heating system. The consequence of pressure redistribution is the equalization of temperatures between the first and last batteries.

The arrangement of any apartment or private house is a very important factor comfortable stay person. One of the main elements of the home is the heat source. For any private house, for example, a one-story house, or apartment, one-pipe and two-pipe heating systems can be installed. In the first option, installation is considered quite simple. It does not require too much material costs and a long pipeline length.

However, the two-pipe heating scheme is more popular.

The operation of such a system is considered expedient and relevant in our time. Its main advantage, in contrast to a single-pipe network, is that purchasing double the number of pipes required for installation is, as a rule, always justified. This is due to the fact that to create such a heating system there is no need to use pipes with a sufficiently large diameter. The need for fittings, valves and fastenings is also reduced. The difference in the cost of materials for a two-pipe and one-pipe heating system is insignificant, but the effect of using the first option is much higher. In this case, it is quite possible to do all the installation work even with your own hands.

Features of a two-pipe home heating system

The presence of such a heating network in a house always means high-quality and comfortable way heating your home. The two-pipe system design involves installing two pipes into each radiator. In one of them he moves hot water. It is connected in parallel to all heating devices. Water flows back into the system through another pipe, which has already cooled down.

Special taps are installed in front of the radiators. Using them, you can disconnect any heating element from the heat supply. Radiator temperature from hot water with a two-pipe system it will be quite low. But the level of costs will still be lower than in the case of using a single-pipe heating network. In practice, it is customary to distinguish dead-end and direct-flow two-pipe elements.

The installation diagram of any such heating system requires the presence of the following materials:

- water heating means (boiler);

- safety valve;

- cleaning reagents;

- expansion tank;

- water circulation pump;

- radiators;

- pressure gauge for determining pressure;

- additional accessories;

- air exhaust mechanism;

- pipes.

To install the system you will need the following tools:

- hammer;

- drill;

- welding machine;

- adjustable and gas wrench;

- roulette;

- screwdriver;

- level and plumb.

Horizontal type two-pipe system

The main difference between the vertical and horizontal type of heating system depends entirely on the pipes. They connect all devices into a single integral arrangement mechanism. The two-pipe vertical scheme, in contrast to the one-pipe system, is designed to connect all devices to a vertical riser. During its operation, no air locks occur, but installation and installation are more expensive. This type of heating is very suitable for a private multi-storey building, since all floors can be separately connected to a riser.

The horizontal system is relevant for a one-story building and has its own unique advantages. The radiators are connected to the pipeline, which is in the appropriate position. This type of heating is very convenient to install wooden houses and panel-frame buildings that do not have walls. Wiring risers are usually installed in corridors. For horizontal system The following heating scheme is suitable.

This type of heating element includes two main types of connecting thermal components - radiant and serial. The basis of the first type is a separate heat supply to the radiator. The feature of the sequential type of horizontal two-pipe system is based on total number pipelines. Each of the above types has its own advantages. With the beam view, there is no need to control the patency of the chokes, which are located near the boiler, and to regulate the two-pipe heating system. Wherein temperature regime remains unchanged and identical along the entire radial length. One of the main disadvantages of such a heating system is the high consumption of material.

When stretching horizontal wiring along the wall to many radiators, it is practically impossible to maintain high-quality appearance. That's why the best option will hide all the pipes under the screed during construction. The beam system is most practical and expedient to use for one-story house. To heat any premises, it will be beneficial to use a series two-pipe network. This is primarily due to the fact that the heating fluid temperature must always be maintained at the same level.

For correct installation and settings of a horizontal two-pipe heating network, the following nuances must be taken into account:

- complete installation this system usually takes a long period of time;

- all network adjustments must be implemented before the onset of cold weather;

- For a high-quality calculation of a horizontal heating system, you should seek help from a qualified specialist.

Scheme of a two-pipe heating system with an upper type of wiring

The main essence of a vertical two-pipe heating system for a private house or apartment, which distinguishes it from a single-pipe network, is parallel connection radiators into which heat flows from the boiler. A feature of this heating method is the mandatory presence of an expansion tank and the upper installation of the distribution pipeline. The coolant flows from the boiler up through the pipeline, rising evenly along each line to all radiators. The expansion tank is usually installed at the top of the heating circuit.

The main difference between the vertical and horizontal systems is that when installing the latter, all pipes are installed with a slight slope. Water from the thermal heaters is returned back to the return pipeline through return lines, and from there back to the boiler. A special feature of this heating system is the presence of two pipelines - supply and return. Therefore such heating network called two-pipe, not one-pipe.

The water supply system is carried out using a water pipe. If there is no water supply, all liquid should be poured manually through the opening of the expansion tank. It is best to feed the heating system in return when cold water mixed with hot. At the same time, during replenishment, the circulation pressure increases and the level of its density increases. The functional diagram of such a system is shown below.

With this type of two-pipe vertical heating, unlike a single-pipe network, the coolant is heated under strong pressure and moved to the upper level of the attic. After this he goes down the heating radiators. Cooled water is supplied back to the pipes, which are lower than the level of the radiators. With such circulation, the expansion tank helps to automatically remove any air accumulations.

Two-pipe heating system with bottom wiring

A distinctive feature of this heating system is the supply pipeline, which is installed below near the return line. With lower distribution through the supply pipes, water moves from bottom to top. It passes through the return lines and enters the pipe through heating devices. Next, the water moves into the boiler. All air pockets are drained from the heating system using air valves. They must be installed on every radiator. The layout and advantages of the heating network are as follows.

A two-pipe heating network with bottom wiring, as a rule, is designed with one, several, associated or dead-end circuits. In practice, this type of heating system is not used very often. This is due to the fact that air vents must be installed on each final radiator. These systems have a special expansion tank, with the help of which the air mass is drawn into the circulation ring. In this regard, the process of bleeding air from radiators must be carried out once a week. One of the main advantages of the system is the ability to heat the house even before the construction process is completed.

Scheme of a two-pipe heating system

A special feature of the two-pipe system is the presence of two pipes connected to each of the radiators: the upper one with direct current, and the lower one with reverse current. This differs from a single-pipe heating network. The heating network diagram for a private house or apartment includes the following components:

- boiler;

- thermostatic valve;

- car air vent;

- balancing device;

- batteries;

- valve;

- tank;

- pipeline filter;

- temperature manometer;

- pump;

- safety valve.

Working diagram of two-pipe heating for a private two-story house shown below.

The expansion tank must be installed on the top element systems. If your home is equipped autonomous system water supply, then the above element can be combined with a consumable type of water supply tank. The permissible slope of return and supply pipes should not exceed 10 cm over 20 linear meters. During installation, a two-pipe heating system is often divided into two separate bends if the lower distribution pipeline is located directly next to front door. It should be created from the location of the highest point in the system.

If there is an autonomous two-pipe heating network with top-type wiring, it can be realized different scheme installations. It all depends on the location of the expansion tank and the height level from the floor. The optimal solution The tank will be installed in a warm room with free access to it. However, if the upper horizontal supply pipe is located in the middle between the window and the ceiling, then such installation will be very inconvenient. Installing an expansion tank above a ceiling, for example, in an attic, will also be completely wrong from a safety point of view in cold weather.

The process of operation of a two-pipe system will be best if there is a maximum length of pipe for supplying heat. With different diameters of these elements, the quality and efficiency of such a heating network will always increase. This is due to the fact that at the very beginning of the wiring there is the top point of the heat supply pipe. The efficiency of any heating system increases if it has a circulation pump. It has a power that varies from 65 to 110 Watts, and during long-term operation there is no need for additional maintenance.

Thanks to this component, the heating rate of any room increases significantly. But with a two-pipe heating system with an upper type of wiring, the use of such an element will be inappropriate and unnecessary.

A two-pipe heating system has a more complex architecture, and its installation requires a large amount of materials. And, nevertheless, this system is more in demand than a simple one single pipe system heating. A two-pipe heating system consists of two closed circuits, one of which serves to supply heated coolant to the radiators, and the second to drain the already used (cooled) liquid. The use of this system is acceptable for all types of buildings, provided that the layout of the premises itself allows its installation.

Two-pipe heating system

Types and advantages of a two-pipe heating system

Technical feature of the heating system of this type is that it consists of two pipelines. One is used to transport coolant heated in the boiler directly to heating sources - radiators. And the second circuit is necessary for the outflow of already used coolant from the radiators - the cooled liquid that has given up its heat.

A double-circuit heating system has a significant advantage over a single-pipe heating system, in which the heated coolant loses some of the heat even before it reaches the radiators.

In a system such as a passing two-pipe heating system, there is an equal temperature of the coolant entering simultaneously into the heating devices of the system.

Scheme of a two-pipe heating system

Many believe that the cost of a two-pipe system, compared to a simpler one-pipe system, almost doubles - after all, it is necessary to take twice as many pipes. But that's not true. The fact is that in order to properly build a properly functioning one-pipe system, pipes of larger diameter should be used, since they contribute to a more active movement of coolant and waste liquid. And when creating a two-pipe system, pipes of much smaller diameter are used, the cost of which is lower.

The same situation is observed when purchasing additional system components - valves, fittings, connecting elements. Products with larger diameters are more expensive. That is, we can draw a simple conclusion - in fact, purchasing materials for a two-pipe system will not cost you much more than for a single-pipe system. But the efficiency of its work is much higher.

Another significant advantage of a two-pipe system is that in such a heating system it is possible to install valves on each radiator, through which the heating level of the element can be controlled. In addition, through such valves you can also significantly save water and electricity consumption for heating it.

It should be noted that the two-pipe heating system design has another advantage. It lies in comparatively greater aesthetics.

Many owners of houses with a single-pipe system are often upset that a very thick heating pipe cannot be hidden - and this significantly spoils the overall impression of the room. While the pipes used in a more complex two-pipe system are thinner - and hiding them will not be difficult. And even if the pipes are visible, they do not attract much attention.

Considering all the obvious advantages of a two-pipe system - greater efficiency, low cost and aesthetics, you can confidently choose it. This is what most owners of country houses do.

There are two types of two-pipe heating systems - horizontal and vertical 2-pipe heating systems. The main difference between these types is in the axis of the pipeline location. These pipes are used to connect all elements of the heating system. Of course, each type has its own disadvantages and advantages. Common to both types are the following advantages: excellent hydraulic stability and a high level of heat transfer.

Should be installed in one-story buildings where the heating pipeline is quite long. In such houses, connecting heating radiators to a horizontally located system is the most practical solution question.

It is slightly more expensive than the horizontal one. However, since the riser is located vertically, this allows it to be used even in multi-story buildings. In this case, each floor separately cuts into the central heating riser. In addition, the advantage of the vertical type of heating system is that air does not accumulate in it - if bubbles arise, they immediately rise vertically, directly into the expansion tank.

Whatever type of system you choose, you should keep in mind that balancing must be carried out. When choosing a vertical system, balancing a two-pipe heating system requires the riser itself. When horizontal adjustment of a two-pipe heating system takes place, the loops are subject to it.

Types of wiring for a two-pipe system

Regardless of which type of two-pipe heating system you choose for own home, there is another system for dividing it - according to the principle of organizing wiring. In the photo you can see two different wiring diagrams. Each has its own advantages and disadvantages of a two-pipe heating system.

In this case, the pipeline with hot coolant is laid in the basement or basement. It is also possible to lay pipes underground. With this type of installation, it should be taken into account that the pipes for returning the waste coolant back to the boiler must be located even lower. Using the principle of horizontal wiring requires some deepening of the boiler - only in this case will water move from the radiators to heating element as quickly as possible. In addition, there is a need to connect an additional line - an overhead line - to the circuit. With its help it will be possible to remove air from the system.

To construct it, it is necessary to place the expansion tank at the highest point of the pipeline. The branching of the system is also carried out there. Being more practical, overhead wiring cannot be installed in buildings that do not have an attic.

You can choose the most suitable type of wiring, regardless of what type of supply pipe arrangement is used in your home.

However, there are some requirements that should definitely be taken into account. In particular, for houses in which a two-pipe vertical heating system is installed, the most appropriate is to use lower wiring. This is explained by two-pipe heating with bottom wiring allows for maximum benefit use the pressure that arises in the system at quite big difference coolant and waste liquid. Of course, if architectural features buildings do not allow the use of lower wiring, the use of upper wiring is acceptable.

It should be taken into account that the use of upper wiring both for supplying coolant to radiators and for returning return to the boiler is not The best decision, since sludge may accumulate in the lower elements of the system.

In fact, the classification of a two-pipe heating system is very multifaceted.

Another principle of separation is the direction of coolant flow. According to this criterion, the system can be:

- direct flow. In this case, the direction of movement of the coolant and return coincide.

- dead end. When using a scheme such as a two-pipe dead-end heating system, the hot and waste coolant move in different directions.

Modern systems can be equipped with a special pump, thanks to which the coolant moves more actively. At the same time, natural circulation systems are also often used, in which no additional equipment is used. If you intend to use a two-pipe system in two-story house, then this double-circuit heating must be equipped with a pump.

Heating system with circulation pump

But when installing a two-pipe heating system in a one-story room, you can do without a pump, using some laws of physics to move the coolant naturally. It is important to take into account that for more active natural circulation of the coolant it is necessary to lay heating pipes with a slope directed towards the heating boiler.

However, regardless of the system you use (with forced and natural circulation), a slope must be present.

For systems with forced circulation, it is necessary in case of an unexpected power outage or pump breakdown. In this case, the slope allows the coolant to circulate naturally.

Calculation

When planning a two-pipe system, it is important to carry out a preliminary calculation of the two-pipe heating system, using such a guide as a preliminary diagram of the system (all elements must be indicated on it) and special axonometric formulas and tables.

This simple hydraulic calculation of a two-pipe heating system allows you to determine the optimal diameter of the pipes necessary for the normal functioning of the system and the volume of radiators used. The most commonly used types of calculations are:

- by pressure loss. This method assumes an equal level of coolant temperature in all parts of the system.

- calculations taking into account the value of conductivity and resistance. In this case it is assumed different meaning temperature indicators.

As a result of using the first method, you can obtain very accurate data showing the level of resistance in the circuit. The second method shows the temperature in each individual segment of the system, as well as the approximate coolant flow.

Principles of installation of a two-pipe system

When installing a two-pipe system, one should take into account quite a large number of requirements and rules. Only their full compliance will allow you to create the most efficient heating system and carry out the correct installation of a two-pipe heating system:

- a two-pipe closed or open heating system consists of two circuits - the upper one serves to supply heated coolant to the radiators, and the lower one serves to drain the waste liquid.

- pipes should be laid with a slight slope. It should be made towards the last radiator of the system.

- the upper and lower lines must be parallel.

- the central riser must be insulated - otherwise there will be a loss of coolant at the stage of its movement to the radiators.

a two-pipe reversible heating system must have several taps that will allow water to be drained from individual areas if repairs become necessary.

- the pipeline should contain as few corners as possible.

- The expansion tank should be located at the highest point of the system.

- taps, connections and other elements of the system must be equal to diameter pipes used.

- in case the pipeline is used steel pipes, it is necessary to create a system of fasteners that will support the pipe. The distance between supports should not exceed 1.2 meters.

The sequence of connecting elements in how to make a two-pipe heating system is simple:

- A central heating riser is connected to the heating boiler.

- in the upper part, the central riser is connected to the expansion tank.

- A splitter comes from the tank, directing the pipes to the radiators.

- the waste liquid discharge line is laid parallel to the supply pipes. It should be embedded in bottom part heating boiler.

- the pump is installed at the most convenient point - most often at the inlet (outlet) of the boiler.

This type of heating system is quite efficient. Today there are a large number of boiler models that require automatic control coolant heating level. You can watch a video on how to make double-circuit heating with your own hands below.

Today, several heating systems are known. Conventionally, they are divided into two types: single-pipe and double-pipe. To determine the best heating system, you need to have a good understanding of how they work. With this you can easily make the choice of the most suitable heating system, taking into account all the positive and negative qualities. Except technical characteristics When selecting, you must also take into account your financial capabilities. And yet, is a single-pipe or two-pipe heating system better and more efficient?

Here are all the parts that are installed in each system. The most important are:

Positive and negative properties of a single-pipe system

It consists of one horizontal collector and several heating batteries, connected to the collector by two connections. Part of the coolant moving through the main pipe enters the radiator. Here, heat is transferred, the room is heated and the liquid is returned back to the collector. The next battery receives liquid whose temperature is slightly lower. This continues until the last radiator is filled with coolant.

Main hallmark A one-pipe system is the absence of two pipelines: return and supply. This is the main advantage.

There is no need to lay two highways. Much fewer pipes will be needed, and installation will be simpler. There is no need to break through walls or make additional fastenings. It would seem that the cost of such a scheme is much lower. Unfortunately, this does not always happen.

Modern fittings allow automatic adjustment of the heat transfer of each individual battery. To do this, it is necessary to install special thermostats with a large flow area.

However, they will not help get rid of the main drawback associated with the cooling of the coolant after it enters the next battery. Because of this, the heat transfer of the radiator included in the overall chain decreases. To retain heat, it is necessary to increase the battery power by adding additional sections. This type of work increases the cost of the heating system.

If you make the connection of the device and the main line from pipes of the same diameter, the flow will be divided into two parts. But this is unacceptable, since the coolant will begin to cool quickly when it enters the first radiator. In order for the battery to be filled with at least a third of the coolant flow, it is necessary to increase the size of the common collector by approximately 2 times.

What if the collector is installed in a large two-story house with an area exceeding 100 m2? For normal coolant passage, pipes with a diameter of 32 mm must be laid throughout the circle. To install such a system, large financial investments will be required.

To create water circulation in a private one-story house, you need to equip the single-pipe heating system with an accelerating vertical collector, the height of which must exceed 2 meters. It is installed after the boiler. There is only one exception and that is pumping system, equipped wall-mounted boiler, which is suspended at the desired height. Pump and everything additional elements also lead to higher prices for single-pipe heating.

Individual construction and single-pipe heating

Installing such heating, which has a single main riser in a one-story building, eliminates the serious drawback of this scheme, uneven heating. If something like this is done in multi-storey building, heating upper floors will be noticeably stronger than heating lower floors. As a result, an unpleasant situation will arise: it is very hot above, and cold below. Private cottage usually has 2 floors, so installing such a heating scheme will allow you to evenly heat the entire house. It won't be cold anywhere.

Two-pipe heating system

The operation of such a system differs somewhat from the scheme described above. The coolant moves along the riser, entering each device through outlet pipes. Then it returns through the return pipe to the main pipeline, and from there it is transported to the heating boiler.

To ensure the functionality of such a scheme, two pipes are connected to the radiator: through one the main supply of coolant is carried out, and through the other it returns to the common line. That is why they began to call it two-pipe.

The installation of pipes is carried out along the entire perimeter of the heated building. Radiators are installed between pipes to dampen pressure surges and form hydraulic bridges. Such works create additional complications, but they can be reduced by creating the right circuit.

Two-pipe systems are divided into types:

Main advantages

What positive qualities have such systems? Installation of such a heating system makes it possible to achieve uniform heating of each battery. The temperature in the building will be the same on all floors.

If you attach a special thermostat to the radiator, you can independently regulate the desired temperature in the building. These devices do not have any effect on the heat transfer of the battery.

The two-pipe piping makes it possible to maintain the pressure value when the coolant moves. It does not require the installation of an additional hydraulic pump high power. Water circulation occurs due to gravitational force, in other words, by gravity. If the pressure is poor, you can use a pumping unit low power, which does not require special maintenance and is quite economical.

If you use shut-off equipment, various valves and bypasses, you will be able to install systems in which it becomes possible to repair only one radiator without turning off the heating of the entire house.

Another advantage of two-pipe piping is the ability to use any direction of hot water.

Operating principle of the passing circuit

In this case, the movement of water through the return and main pipes occurs along the same path. In a dead-end circuit - in different directions. When the water in the system is in the same direction and the radiators have the same power, excellent hydraulic balancing is obtained. This eliminates the use of battery valves for pre-setting.

With different power radiators, it becomes necessary to calculate the heat loss of each individual radiator. To normalize the operation of heating devices, you will need to install thermostatic valves. This is difficult to do on your own without specific knowledge.

Hydraulic gravity flow is used when installing a long pipeline. In short systems, a dead-end coolant circulation pattern is created.

How is a two-pipe system maintained?

In order for the service to be high-quality and professional, it is necessary to perform a whole range of operations:

- adjustment;

- balancing;

- setting.

To adjust and balance the system, special pipes are used. They are installed at the very top of the system and at its lowest point. The air is discharged after opening the upper pipe, and the lower outlet is used to drain the water.

Excess air accumulated in the batteries is released using special taps.

To adjust the system pressure, a special container is installed. Air is pumped into it with a conventional pump.

Using special regulators that help reduce the water pressure into a specific radiator, a two-pipe heating system is configured. After redistributing the pressure, the temperature in all radiators is equalized.

How can you make a two-pipe from a single pipe?

Since the main difference between these systems is the separation of streams, this modification is quite simple. It is necessary to lay another pipeline parallel to the existing main. Its diameter should be one size smaller. Near the last device The end of the old collector is cut off and tightly closed. The remaining section is connected in front of the boiler directly to the new pipeline.

A passing water circulation pattern is formed. The exiting coolant must be directed through a new pipeline. For this purpose, the supply pipes of all radiators must be reconnected. That is, disconnect from the old collector and connect to the new one, according to the diagram:

The remodeling process can present additional challenges. For example, there will be no space to lay a second highway, or it will be very difficult to break through the ceiling.

That is why, before embarking on such a reconstruction, you need to think through all the details of the future work. It may be possible to adjust a one-pipe system without making any alterations.

Almost all heating systems currently available in any buildings and structures can be classified into one of the two classes mentioned in the title of this article.

The question of whether a single-pipe or two-pipe heating system is better can only be answered by carefully understanding the advantages and disadvantages of each of the options considered.

Characteristics of a single-pipe home heating system

Which heating system is more efficient, one-pipe or two-pipe? It is impossible to answer this question unambiguously.

Single-pipe CO has all the basic elements inherent in any heating system. The main ones are:

- A heating boiler that runs on any type of fuel that is most available at the location of the heated building. It can be a gas, solid fuel or intended to operate on liquid fuel. The type of fuel used by the boiler does not have any effect on the heating circuit;

- Pipes through which the coolant circulates;

- Shut-off equipment for various purposes (valves, gate valves);

- Heating appliances and thermometers;

- Valves for bleeding air. Placed on radiators (Maevsky taps) and at the top point of the CO;

- Drain tap (at the lowest point of CO);

- Expansion tank of open or closed type.

Advantages of using single pipe systems

The difference between a one-pipe heating system and a two-pipe one is that the first is by far the simplest and in an effective way heating buildings up to 150 m2.

Installation of a circulation pump and use of modern technical solutions make it possible to guarantee the required temperature parameters in heated rooms. Therefore, answering the question, what to choose, a single-pipe or two-pipe heating system, including undeniable advantages The first system should be noted:

Versatility of installation. Such a system can be installed in a building of any configuration, and a closed loop guarantees the movement of the coolant along the entire perimeter of the heated premises.

Unlike two-pipe, single-pipe CO can be installed in such a way that heating of the premises begins from the coldest side of the building (north), regardless of where the boiler is installed, or from the most important rooms (children's room, bedroom, etc.).

Installation of the system requires a minimum number of pipes and shut-off and control equipment; complete installation of the system is carried out in much less time than a system with two pipes. All this allows you to get serious savings in funds allocated for construction work.

The system allows the installation of pipes directly on the floor or under it, which allows you to implement any design solutions in the premises.

The scheme provides for serial and parallel connection of heating devices, which makes it possible to control and regulate the temperature in them;

If certain installation requirements are met, the system can be made in a non-volatile version. In the event that the pump stops due to a power failure, the coolant supply line is switched to a parallel branch. In this case, CO, from the version with forced circulation (PC), switches to natural circulation (EC).

Disadvantages inherent in the specified CO option

Two-pipe or one-pipe heating system for a private house? When assessing the pros and cons, it should be taken into account that the main disadvantage of single-pipe CO is the fact that the heating devices are connected in series. And this, during operation, eliminates the possibility of effectively adjusting the temperature in one of them, without it affecting the remaining radiators.

The factor influencing the choice is whether a two-pipe or one-pipe heating system for a private house will be installed at your site; do not forget about the disadvantage of the latter, such as increased two-pipe version, system pressure. This can be achieved by increasing the power of the circulation pump installed in the system, which entails an increase operating costs and increases the likelihood of leaks, and also requires more frequent addition of coolant to the system.

The system requires vertical filling. And this automatically determines the location of the expansion tank attic space and, accordingly, solving the issue of its insulation.

If such a system is installed in a two-story building, then another problem arises. The temperature of the water entering the first floor may differ by almost 50% from that initially supplied to the second floor. To avoid this, it is necessary to install additional jumpers on each floor, and the number of sections of heating devices on the first floor should significantly exceed that installed on the second.

Which heating system is more efficient, one-pipe or two-pipe? We have already considered the first one. Let's look at the second one.

Such a system a priori implies the presence of two pipelines located around the perimeter of the heated room. Radiators are inserted between them, which dampen pressure drops and create hydraulic bridges. However, the problems created by this can be leveled by correct configuration CO.

- Two-pipe systems can be vertical and horizontal, depending on the location of the supply and return (parallel to the ceilings or perpendicular to them). However, it should be understood that mounted in apartment buildings the circuit is essentially a horizontal two-pipe CO.

A two-pipe vertical one will be obtained in the case when the radiators are installed not in the gaps of the risers (as in the case described above), but between the supply and return.

- Associated and dead-end SOs. The first type includes systems in which hot water, passing through the radiator, moves in the same direction along the return line. If after the heating device the direction of movement of the coolant changes, the system is classified as a dead end.

The required option is selected taking into account the presence of doorways on the CO pipe laying line, which are quite difficult to bypass; it is easier to return the water in the direction in which it came.

- With bottom and top filling.

- With natural (EC) and forced (PC) circulation.

Advantages and disadvantages of the system

Schemes of one-pipe and two-pipe heating systems are compared according to their inherent advantages and disadvantages. The advantages of the second system are:

- The supply of coolant to all heating devices at the same temperature, which allows you to set your own required temperature for a specific room;

- Lower pressure losses in the lines, which allows the use of a lower power pump (saving operating costs);

- The system allows installation in buildings of any size and number of floors;

- Availability shut-off valves allows you to perform preventive maintenance and repairs without stopping the entire CO.