A cinder block house, the pros and cons of such a structure! A house made of cinder block - we build a durable home ourselves. Is it worth building a house from cinder block?

Read also

Cinder block is a masonry wall stone made by vibrocompression or natural shrinkage in mortar forms based on cement, sand and metallurgy by-products. Expert opinions and reviews from building owners are ambiguous; this is largely due to the method of production (handicraft or factory), its type and properties. The generally accepted opinion is that self-produced material is excellent for the construction of garages, sheds and other low-rise buildings, but for residential buildings Only certified products are required; in the latter case, construction cannot be called budgetary.

Description of the material, types of raw materials used for production

Technical manufacturing conditions, shape, dimensions are regulated by GOST 6133-99. According to this standard wall stones are represented by solid and slotted rectangular products with flat, grooved or scalloped ends. When preparing the mixture for their formation, only cement is used as a binder, in the form of coarse and fine filler - sand and screenings and products of crushing slag, crushed stone, gravel, broken bricks, hardened cement mortar, glass or concrete, expanded clay, volcanic ash, ash, sawdust, etc. The size of the fractions is limited to 10 mm for large-slot, 20 for solid. The final cost is low, availability is considered the main advantage of the product.

Initially, only metallurgical by-products were used to make cinder blocks, but now the term is applied to all concrete wall stones produced using vibrocompression. Average density for slotted types it is limited to 1650 kg/m2 (in private construction, products are selected in the range of 450-1650), for solid ones - no higher than 2200. The weight depends on the hollowness and porosity of the sludge, a cinder block of a standard size 390 × 190 × 188 with a share of cracks of 40% weighs 10 kg, solid – 28.

Main properties and characteristics

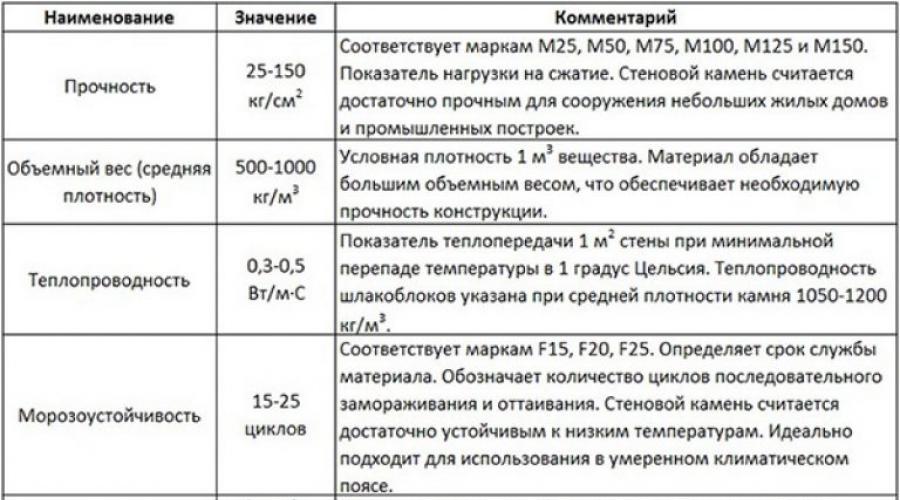

The performance of blocks depends on the type and filler; solid ones are considered the most durable (from 35 to 125 kg/cm2) and are suitable for masonry load-bearing structures low-rise buildings. The material is non-flammable, does not shrink, and is resistant to fungus (but only if it has good waterproofing). The thermal conductivity coefficient varies from 0.27 to 0.65 W/m °C; the more porous and loose the filler, the higher the thermal insulation properties and the lower the strength. Negative manifestations are associated with hygroscopicity - the high water absorption of cinder blocks is considered their definite disadvantage; they require mandatory protection from external moisture.

Another disadvantage is associated with the high radiation background of raw materials or their release hazardous substances, for the construction residential buildings Only certified material is suitable. The harm to health has not been proven, but according to reviews, allergy sufferers and people with illnesses feel unwell in such houses respiratory tract. The problem is solved by purchasing cinder blocks from responsible manufacturers and reliable interior finishing (in this case, completely closing the walls with simultaneous insulation). When making it yourself, it is recommended to use aged slag (at least 2 years) and conduct an examination for radioactivity.

Pros and cons of blocks, comparison with expanded clay concrete products

Clear advantages include:

- Affordable cost, especially for hollow ones.

- The possibility of laying cinder blocks with your own hands and making them at home. A definite plus here is low cost filler.

- Solid species have fairly high noise absorption abilities.

- Fire resistance.

The disadvantages are:

- Hygroscopicity.

- The need for mandatory finishing, including due to the external unattractiveness of the blocks (with the exception of decorative ones).

- Problems when laying communications, at least in solid products based on metallurgical slag.

- Low geometric accuracy and deviations from dimensions are regulated by GOST, but even for responsible manufacturers they can reach 1 cm, and for homemade products – even more. This leads to an increase in thickness masonry mortar, installing them on special glue is impossible, the formation of cold bridges is inevitable. As a result, a cinder block house needs external insulation. Increasing the thickness of the walls does not solve the problem and only leads to stricter requirements for the foundation.

- Need for verification of environmental performance.

It is easy to see that most of the disadvantages of cinder block are eliminated when using a safer filler. Its separate and improved variety is considered to be products made from expanded clay concrete, with a proportion of baked clay up to 35%. The manufacturing process of factory expanded clay blocks is different the last stage– heat treatment, which increases their resistance to moisture and other external influences. A comparison of the main advantages and disadvantages is given below (relevant only for certified products):

| cinder block | Expanded clay concrete block | |

| Strength, kg/cm3 | 25-125 | 5-500 |

| Weight | With equal dimensions and hollowness, expanded clay block is 25-30% lighter | |

| Average number of freezing cycles | 20 | 50 |

| Water absorption,% | 75 | 50 |

| Shrinkage,% | absent | |

| Thermal conductivity, W/m °C | 0,27-0,65 | 0,14-0,66 |

| Environmental friendliness | Conditional, possible release of harmful substances and deviation background radiation from normal | Does not release toxins |

Reviews from experts and home owners

“I built a garage from factory hollow cinder blocks, and did all the work myself. The advantages include the simplicity of masonry; no special skills are required for this. I didn’t find any disadvantages, but I don’t recommend dropping or hitting the blocks with metal. In total, with dimensions 6x4 and a height of 3 m, it took 600 pieces; taking into account delivery and unloading, the products cost me 22,000 rubles. The garage hasn’t lasted long so far – 1 year, but I don’t see any cracks or shrinkage.”

“I built a garage from factory hollow cinder blocks, and did all the work myself. The advantages include the simplicity of masonry; no special skills are required for this. I didn’t find any disadvantages, but I don’t recommend dropping or hitting the blocks with metal. In total, with dimensions 6x4 and a height of 3 m, it took 600 pieces; taking into account delivery and unloading, the products cost me 22,000 rubles. The garage hasn’t lasted long so far – 1 year, but I don’t see any cracks or shrinkage.”

Alexander, Moscow.

“With all the advantages of cinder block, I do not recommend using it for the construction of a residential building with permanent residence, the characteristics of its background radiation may exceed the norm, this material is classified as conditionally environmentally friendly. For outbuildings and rarely visited objects, its significance is not so relevant; there are no restrictions on its use. Regardless of the purpose of the building, the blocks need protection from external moisture; exceptions are made only for decorative varieties.”

“With all the advantages of cinder block, I do not recommend using it for the construction of a residential building with permanent residence, the characteristics of its background radiation may exceed the norm, this material is classified as conditionally environmentally friendly. For outbuildings and rarely visited objects, its significance is not so relevant; there are no restrictions on its use. Regardless of the purpose of the building, the blocks need protection from external moisture; exceptions are made only for decorative varieties.”

Roman, Ekaterinburg.

“I built my own bathhouse from factory-quality cinder blocks, the costs were high, but in my opinion justified. Used for marking and laying finished project, I advise you to immediately take into account all possible communications, including interior walls, I personally forgot to leave a hole for the pipes, then I spent a lot of effort on drilling. Insulation of floors and walls and good waterproofing bottoms are required, it is enough to cover everything from moisture from the outside. I initially protected the facade of the bathhouse with cheap siding, and after 3 years I covered it facing bricks, I didn’t notice much difference in heat retention.”

“I built my own bathhouse from factory-quality cinder blocks, the costs were high, but in my opinion justified. Used for marking and laying finished project, I advise you to immediately take into account all possible communications, including interior walls, I personally forgot to leave a hole for the pipes, then I spent a lot of effort on drilling. Insulation of floors and walls and good waterproofing bottoms are required, it is enough to cover everything from moisture from the outside. I initially protected the facade of the bathhouse with cheap siding, and after 3 years I covered it facing bricks, I didn’t notice much difference in heat retention.”

Igor, Moscow.

“I bought an old cast house with a good, well-established rubble foundation and decided to replace the walls with cinder block ones. Due to the lack of free time, I entrusted the purchase of materials and masonry to professionals, all the work on the construction and insulation of the facade took a little more than 4 months, I did not notice any disadvantages, I consider the cost acceptable. I did the interior finishing myself, after reading the reviews, I treated the walls with concrete contact, and as a result, the plaster went on without any problems.”

“I bought an old cast house with a good, well-established rubble foundation and decided to replace the walls with cinder block ones. Due to the lack of free time, I entrusted the purchase of materials and masonry to professionals, all the work on the construction and insulation of the facade took a little more than 4 months, I did not notice any disadvantages, I consider the cost acceptable. I did the interior finishing myself, after reading the reviews, I treated the walls with concrete contact, and as a result, the plaster went on without any problems.”

Sergey, Voronezh.

“For those who decide to build a cinder block bathhouse, I advise you to pay Special attention waterproofing floors and internal insulation. Wood flooring It definitely won’t work here, but concrete screed, preferably on top of filled expanded clay or foam glass. A stable foundation is required, perfect option– reinforced tape. If all the rules are followed, the bathhouse will retain heat well and will last a long time; if not, it will collapse from dampness, starting from the bottom.”

“For those who decide to build a cinder block bathhouse, I advise you to pay Special attention waterproofing floors and internal insulation. Wood flooring It definitely won’t work here, but concrete screed, preferably on top of filled expanded clay or foam glass. A stable foundation is required, perfect option– reinforced tape. If all the rules are followed, the bathhouse will retain heat well and will last a long time; if not, it will collapse from dampness, starting from the bottom.”

Leonid, Rostov-on-Don.

Before you start building a cinder block house, the pros and cons of which we discussed above, it is worth considering all the points when laying the foundation, construction and further operation of the building.

First of all, you should correctly calculate the amount of material required. The slag block mainly has standard sizes. This greatly helps in determining how many blocks are needed per 1 m2. Then an estimate is drawn up, which will help not only to fix the number of all Supplies, but will also display the estimated cash costs. Correct calculations for initial stage will help eliminate future errors when construction work. It is also imperative to adhere to the rules for laying slag stone, because this will affect the safety, strength, long term operation of the building.

Transportation and storage of blocks is carried out at wooden pallets.

There are some nuances that greatly simplify construction process and help you save:

- Laying cinder blocks is done with minimum quantity ordinary construction tools- trowel, construction shovel, container for preparing mortar, level.

- It is advisable to place a stand nearby in advance on which the products for top installation will be placed to save time.

- The masonry layer (its thickness) should be no more than 15 mm, otherwise it can lead to a significant loss of internal heat.

- It is more advisable to mix the solution using a concrete mixer.

- Laying begins from the corner. Excess mortar, which appears after pressing, must be immediately leveled with a trowel, otherwise lumps may appear.

We discussed above which cinder block is better for building a house. But environmental safety of this material leaves much to be desired. As already mentioned, recycled waste from various industries is used in the production of slag blocks. Therefore, it is more advisable to use it in the construction of warehouses, hangars, garages, etc. If you want to build your own secluded “nest”, which must meet all the requirements of a living space, such as environmental friendliness, safety, thermal conductivity, we advise you to listen to the advice and choose expanded clay concrete for this purpose. Our database contains trusted suppliers of expanded clay cinder blocks throughout Russia, and prices are lower thanks to live competition.

Currently, there is a huge variety of building materials. They all have their advantages and disadvantages. And many people who want to build their own home have a question: what is the best material to build a house from? Relatively recently, a material such as cinder block appeared on the building materials market.

Unfortunately, there are no ideal materials for building a house. Many factors influence which material to choose. It is necessary to understand that, no matter what material is chosen, proper insulation at home will help you save on heating costs in the future.

Cinder block houses

Houses made of cinder block, like other building materials, have their pros and cons. The biggest advantage is its low cost and availability of material.. But the disadvantages are very significant.

It is better to build a cinder block house with your own hands, it will be cheaper. In addition, this material itself is one of the cheapest building materials. Moreover, you can make cinder blocks yourself. Moreover you will only have to spend money on cement; all other components can be found for free or very inexpensively.

For self-made For quality cinder blocks, it’s better to get a vibrating machine

The composition includes the following materials:

- cement;

- sand;

- water;

- slag, which can be almost any construction and industrial waste: broken bricks, crushed stone screenings, broken glass, metallurgical waste, metal shavings, etc.

If we talk about a house made of cinder blocks for permanent residence, then the reviews of the owners of such houses are completely different. However, this material has enough more cons than advantages, and they are very significant.

Because cinder block contains many wastes from various industries, it it can be assumed that this material is not environmentally friendly. Therefore, it is mainly used in the construction of low-rise non-residential buildings, outbuildings and various outbuildings. For example, for building a garage, such material is simply ideal.

Because cinder block contains many wastes from various industries, it it can be assumed that this material is not environmentally friendly. Therefore, it is mainly used in the construction of low-rise non-residential buildings, outbuildings and various outbuildings. For example, for building a garage, such material is simply ideal.

But everyone comes from their own preferences. For those who do not consider the disadvantages significant, they can easily build a house from cinder blocks.

If you buy industrially produced cinder blocks, the manufacturer must indicate the characteristics of the material. But most of the blocks are produced in a makeshift way on a small vibrating machine operated by one or more people. Naturally, it is almost impossible to predict the characteristics of a material obtained in this way, because different manufacturers use different components and different method production.

In addition, if components are used that deteriorate over time, the material will not last long. AND it is impossible to say how durable this or that cinder block will be.

Since the block is not environmentally friendly pure material and cinder block walls can highlight harmful substances. Because harmful substances can negatively affect organs respiratory system and the body as a whole.

Cinder blocks industrial production are free from the above disadvantages and have parameters guaranteed by the manufacturer

There are several types of blocks:

- full-bodied;

- hollow;

- half blocks;

- decorative blocks.

For the construction of walls, hollow cinder blocks are usually used so that the load on the foundation is less. A a solid block can weigh 22-28 kg, therefore, such a cinder block is used in the construction of the foundation, ground floors, columns, load-bearing structures.

This leads to another significant drawback – heavy weight block. Even hollow blocks weigh 18-22 kg, which is a lot during construction, compared to cellular concrete . Firstly, there will be a large load on the foundation, so the foundation must be made very massive and, therefore, expensive. Secondly, working with the material is very difficult, because during construction high wall It will be difficult to lift it up.

The final advantages and disadvantages of cinder block houses.

The final advantages and disadvantages of cinder block houses.

Pros:

- cheapness and availability;

- masonry can be done with your own hands;

- can be made independently;

- high speed of construction. Since the block has big sizes, the speed of construction of a building increases several times, compared, for example, with ordinary brick;

- a house made of such material is not subject to combustion;

- good block geometry.

Minuses:

- the heavy weight of the blocks, which can place an increased load on the foundation;

- expensive foundation;

- walls can become radioactive;

- cinder block house is not environmentally friendly;

- low frost resistance – F15-35;

- unattractive appearance. Therefore, cladding is required various materials what will affect the budget;

- any, even the slightest, movement of the foundation can affect the structure as a whole, which will lead to cracking of the material;

- plaster can fall off cinder block walls over time.

The outer sides of cinder block walls are subject to mandatory thermal insulation and moisture protection

The disadvantages are quite serious, so you should think several times before starting to build a house from blocks. It is also necessary to understand what the house will be used for - for permanent or temporary residence.

Foundation for a cinder block house

When choosing the type of foundation for a cinder block house, you need pay attention to the following factors:

- soil type;

- soil freezing depth;

- number of storeys of the building;

- type and purpose of the building;

- level groundwater.

Since a cinder block house is susceptible to moisture, the foundation must be high to prevent moisture from affecting the house. The foundation should rise above the ground by approximately 0.7 meters. In addition, it must be well insulated.

If the future house will have one floor, then there is no need to build an overly powerful foundation, because the pressure on it will not be very strong.

Typically, the foundation for a cinder block house is made as follows:

- a trench is dug, 50 cm deep;

- a sand and gravel cushion is poured into the trench;

- formwork is being installed, which will rise above the ground level by 0.7 meters;

- the reinforcement frame is installed according to calculations;

- The formwork is filled with concrete mortar.

Cinder blocks are laid on the frozen cement mortar foundation, which was previously insulated.

Price category

As for the financial side of the issue, a house made of cinder blocks will cost a fairly low price compared to other materials.

Price for 1 piece of cinder block:

Homemade cinder blocks will cost even less, but their quality and performance characteristics will be unpredictable

Before building a house from cinder blocks, it is necessary to draw up appropriate house plans. This procedure is half the success.

To save even more on building a house, You can make cinder blocks yourself. In this case, the costs will only go to the purchase of cement; other materials can be obtained for free. If you get a special vibrating machine, you can make cinder blocks even faster.

When facing a cinder block house with bricks, it is necessary to leave a small air gap between the brick and the cinder block to prevent moisture from getting on the cinder block. Otherwise, the moisture that evaporates from the wall will be reflected from the brick and go back into the cinder block. And this one the material does not tolerate moisture and is destroyed under its influence.

Before purchasing a cinder block, it is necessary to measure the level of radioactivity of the material. Otherwise, harmful substances will be released from the walls and negatively affect health.

Conclusion

Building a house from cinder blocks is considered profitable, but at the same time, we must not forget that this material is not environmentally friendly, and moreover, it has many disadvantages. Therefore, when choosing material for building a house, you need to proceed from your own needs.

The pros and cons of a cinder block house based on the owner’s review are presented in the video:

When choosing a worthy material for construction, the owner's review of a cinder block house may come in handy first. This building material was once widely used for the construction of the various kinds, why has it become quite familiar and by inertia already trustworthy.

At the moment, cinder block is perhaps the most inexpensive building material, so the idea of building something out of it seems very tempting. Indeed, in some cases, a cinder block turns out to be 20 percent cheaper than a brick. On the other hand, more modern materials are intensively praised by manufacturers. They often compare their products to cinder blocks, emphasizing that certain parameters she surpasses him.

Construction is a capital thing, it requires substantial financial investments, which means it requires a comprehensive assessment of the prospects for the future structure. Without proper analysis and comparison, there is a risk of not fully realizing your plans.

Owner's review of a cinder block house from this point of view, it will be valuable precisely because the owner has already lived in it and can tell how much the building meets his expectations. The so-called inside view, which will help you understand the nuances. And if hopes are not met in some way, it can suggest what additional actions should be taken, or what mistakes should be avoided during construction.

The main thing is the material

First of all, developers who have tested cinder block in action advise you to carefully and carefully consider its choice. Specifications of this building material are highly dependent on the fillers added during casting. And if the manufacturer decides to save on them, then your construction and its result will bring nothing but grief in the future.

When purchasing, carefully ask what exactly was added to the cinder block. It is desirable that the fillers are environmentally neutral (if not clean). Expanded clay, sawdust, shell rock, crushed stone, brick chips. Chemically active components will not only endanger the health of people living in a house made of such cinder blocks, but will also make it very short-lived.

You need to check the method of making cinder blocks no less carefully. If it was produced without the participation of a vibrating machine, it will be less durable and reliable. This material is suitable for a garage or shed, but not for a home.

To ensure that the cinder block is of the correct strength for your purposes, do a simple test: take a 15mm nail and try to stick it into any block. If he enters, even with difficulty, this is not what you need.

Construction Features

When planning to use cinder block to build walls, we must not forget about its hygroscopicity - this is the main quality of the building material, which is not approved by all owners of cinder block houses. During the construction process, they advise avoiding some of the mistakes made by predecessors.

Material lying on the ground awaiting its turn absorbs water, which deteriorates the quality of the wall and prolongs the setting time of the solution. Developers who have noticed this recommend either covering the ground with construction polyethylene, or placing cinder blocks on wooden pallets that rise at least 10 centimeters above the ground. Due to the instability of the material to moisture, almost immediate construction of the roof and the construction of a high (up to 70 centimeters) foundation with reinforced waterproofing are also required.

The material itself has good thermal insulation properties. However, thick seams between elements reduce its heat resistance. The optimal indicator is no more than 1 cm.

The hygroscopicity of cinder block requires preliminary consideration of external waterproofing. In addition, it must be arranged immediately after their construction is completed.

You should know that interior work will be complicated by poor adhesion of the plaster to the wall. Need additional processing walls

If you take into account all these nuances, a cinder block house will last a long time and will not cause trouble in the future.

Of the noted advantages

Despite some shortcomings and difficulties, in general, the owners of houses made of this material were satisfied with their choice. They were most pleased with the following features.

Absolute Fire safety. A cinder block is not only incapable of igniting, but also does not support a flame. Moreover, after a fire the walls remain intact, except perhaps smoked. In such force majeure circumstances, brick buildings are sometimes destroyed by even 70%.

- High strength: Even hurricanes are not afraid of the house, especially if the walls are reinforced with steel rods during its construction.

- Ease of laying. Working with cinder block is many times easier than working with the same brick. Even a non-professional can handle the construction of walls.

- Excellent sound insulation. If there is a highway next to the house, even a convoy of trucks will not particularly disturb the residents, except through the double-glazed windows.

- Resistance to biological degradation. The house is not afraid of insects, fungal colonies, or rodents.

Few developers know, but many companies offer free projects for the construction of cinder block houses. If you are planning to build from this material, take an interest in such promotions in your region - this will significantly reduce upcoming costs. Moreover, the projects are designed for specific conditions, taking into account the type of soil and climatic features. And what is offered is not dull boxes, but completely modern, often original homes.

conclusions

In general, almost every owner review of a cinder block house can be considered positive. Someone calls it necessary exterior finishing- but they do it with almost any material for building a house. Some are dissatisfied with the need for waterproofing and insulation - but, again, most buildings require such measures.

If the cinder block is of high quality (and most reputable stores check the shipments they receive for toxicity, strength and radioactivity), then your house can stand for a whole century and not require overhaul.

Only those who live in a very humid climate and in flooded areas will have to refuse to use this material. Not too much cinder block is also recommended for close groundwater - under such circumstances high humidity is certainly observed, and waterproofing on all sides eliminates the low cost of building materials.

Cinder block is considered relatively cheap building material with sufficient strength. And also its relatively light weight and dimensions allow you to carry out the masonry yourself, without having a highly qualified mason.

Advantages

- Does not burn, like most concrete composites.

- Many available free projects cinder block houses.

- Has good sound insulation properties.

- Biologically stable (not susceptible to rotting).

- If the production technology is followed, the service life is up to 100 years.

Flaws

- Unresistant to atmospheric influences. Walls made of this material require mandatory finishing, because they have an unsightly aesthetic appearance, also under the influence of moisture and other atmospheric phenomena are destroyed.

- Requires mandatory insulation(has high thermal conductivity).

- Often environmentally unsafe because the manufacturer can use cheaper, environmentally harmful material.

Calculations

- The standard size is 200 mm by 400 mm. But there are also half-blocks for constructing partitions (100 mm by 400 mm), the height of both is 200 mm. The manufacturer, of course, can make adjustments.

- The thickness of the walls depends on the climate in which the house is planned to be built. For example, if average temperature in winter about -20ºC, thickness outer wall should be 45 cm.

- Next, the area of the walls and partitions is calculated, from which the area of the doors and window openings. After that, we divide everything by the size of the cinder block and get the quantity. Naturally, when buying you need to take a little more.

Foundation

- Cinder block is relatively heavy material, therefore it must correspond to the expected loads. With a wall thickness of 40-45 cm, the width of the foundation base for a two-story building should be 60 cm, the height should be at least 70 cm. The dimensions and manufacturing technology of the foundation depend on the geological characteristics of the soil on which construction is planned.

- Once the base is poured, it needs to be allowed to sit. Ideally, you need to fill in early spring when there is no longer frost, and further work continue in the fall. The minimum period for which concrete gains acceptable strength (about 70%) is two weeks.

- The base is placed on the base of the foundation through waterproofing. The base should be made of stone that is resistant to moisture; rubble is well suited in this regard.

Walls and roof

- Waterproofing (usually roofing felt) is placed on the base, and masonry is laid on top of the mortar. Walls made of cinder block are laid in the same way as those made of brick and other block materials, with the only difference being that filler must be poured into the voids of the cinder block, if it is hollow. It is advisable to use a material with low thermal conductivity (expanded clay, sawdust) as a filler.

- Walls built from cinder block cannot be left uncovered for a long time, due to its low weather resistance.