House made of foam panels. Foam blocks. Video - Building a house from foam blocks

Read also

Foam plastic is considered one of the most the best materials in terms of thermal insulation. At the same time, the relative cheapness makes everything more people insulate your premises in this way. However, there are also other options for using this material.

Foam plastic tolerates temperature changes well and is completely impermeable to steam.

One of the relatively new and original options is the construction of a foam house. Some people will laugh and think it's normal. Dollhouse or just a layout. But in reality, everything is much more serious here.

Main characteristics of a polystyrene foam house

Foam houses were first built in Japan. It was there that experts identified the basic properties of such a material, which make it possible to use it not only as an auxiliary tool, but also as the main material. So, let's take a closer look at the main properties of houses made of foam sheets.

- High thermal insulation. As a rule, a house built from foam plastic will be warm enough even when there is no heating in it. This is facilitated by the special structure of the material, which perfectly retains heat. And if you also heat the house a little from the inside, then even about slight cold It will be possible to forget completely.

- Strength. Oddly enough, foam plastic has sufficient characteristics to ensure the strength of even such complex design like a home. But this is only possible if the right technology installation of sheets.

- Relative fire safety. If you choose to work with sheets High Quality, then you will not need to worry that the house can easily burn down. Moreover for additional protection today there is big choice special means, which will create on the surface protective layer from fire.

- High degree of resistance to fungus, mold and insects. Polystyrene foam is artificial material. And this suggests that it is absolutely not interesting for insects, especially bark beetles or termites. The same goes for fungus. Due to the fact that foam plastic almost does not allow moisture and steam to pass through, there is almost no chance of fungus or mold growing on its surface.

- Environmental Safety. The foam itself is safe for health. But when high temperatures it may still release some harmful substances, like any other modern building material. But if everything is done correctly, they will be reduced to a minimum.

- Financial efficiency. The material is inexpensive compared to other, more serious materials for the construction of buildings and structures. Therefore, even with high consumption you will save a lot of money on installation. In addition, construction does not require heavy lifting equipment, which means additional cost savings.

As a result, we can conclude that construction from foam plastic is very profitable. Of course, it is unlikely that you will be able to quickly and independently build a permanent large residential building from this material. But small room It won’t take much effort or investment to make a couple of rooms.

Return to contents

The necessary tools and foundation preparation

Now let’s look at the process itself, how you can build such a house from polystyrene foam with your own hands.

Figure 1. To create a foundation, it is necessary to lay bars clearly along the entire perimeter, the rest of the area is laid with boards of the same thickness.

In this example we will tell you how to build a small building with a ceiling height of about 3 meters and a total area of approximately 5-10 square meters. You will need the following materials and tools:

- Styrofoam;

- solution;

- pencil and ruler;

- screws and dowels;

- polyurethane foam or glue;

- level.

It all starts, as always, with the foundation. You can do the most ordinary strip foundation- as you prefer. After all, more here depends on the type of soil in the selected area. Once the foundation is poured, it needs to be supplemented. To do this, take appropriately sized support wooden blocks with a cross section of approximately 6 by 5 cm. They must be laid clearly along the entire perimeter of the foundation. The remaining area is laid with boards of the same thickness (Figure 1). Before work, do not forget to treat the wood with compounds that protect against fungus, fire and dampness.

Figure 2. The arch frame is made from special shaped blocks.

The beam is attached to the foundation with anchors. But you can optimize the fastening a little by using auxiliary material polyurethane foam. But do not take extra type foam so that it does not expand much. During work, check everything with a building level.

Next, you need to finish the side walls of the foundation that protrude above the ground. This is best done using a thick decorative stone. He sits down on a regular cement mortar, knocked down with a hammer for secure fixation.

The final stage will be laying a film for moisture insulation and ordinary brick or paving slabs. It is not necessary to use bricks (tiles), but it is advisable, as this increases the reliability of the foundation, protecting it from subsidence. When everything is dry and set, you can begin the main work.

For those who want to build a modern warm and without extra costs house, excellent material will become building blocks made of polystyrene foam. This new product in the construction industry quickly gained popularity.

What are foam blocks for construction?

This is a molded structure of two foam plates with internal bridges. Construction foam blocks in industrial production are available in the following sizes: length up to 200 cm, width up to 100 cm, and thickness can be any, but a multiple of 10 mm.

House built according to latest technology, the walls of which are made of hollow foam blocks filled heavy concrete, also called a thermal house. Therefore, the resulting structure is called a thermoblock, where the foam is, in fact, a permanent formwork. In this case, the concrete, hardening, forms a monolithic frame of the building.

What are the benefits of foam blocks for building a house?

They have a number of undeniable advantages:

- Thanks to the use of this technology, the construction process is greatly accelerated. A house made of foam plastic blocks can be built in two weeks, which cannot be said about a house made of bricks. This does not require a large number of builders and special equipment or equipment.

- Polystyrene foam is environmentally friendly pure material, which does not transmit radioactive radiation. After all, it has long been used for food packaging.

- Since polystyrene foam has excellent sound insulation, a house made from it will have the same property. Therefore, peace and quiet for the inhabitants of the house are guaranteed.

- Blocks for building a house with foam plastic have high thermal insulation qualities - this reduces the cost of heating a house by 10-12 times. The need for heating arises only at temperatures below -5 degrees.

- Due to its low weight compared to brickwork, it becomes possible to use lightweight foundations when building a house. Again, saving the family budget.

- More subtle, but warm walls made from foam plastic blocks allow you to increase the living area.

- Also important property The advantage of foam blocks for construction is their fire safety.

- Foam blocks are resistant to biological influences, microorganisms do not settle on them and they are inedible for various kinds rodents

- Due to the fact that foam blocks for construction are priced much lower than classic building materials, they initially have the correct geometric shape With flat surface, which does not also require additional expenses for labor-intensive wall finishing.

- And most important characteristic, as mentioned above, is the low cost of foam blocks, and accordingly the cost of building the entire house.

But when buying foam blocks for building a house, the price of which is very attractive, you should still take into account the quality of the material. In our store you will find only high quality foam blocks affordable price. You can buy foam blocks for construction on our website with the click of a button. And all your questions will be answered by our highly qualified consultants, who are well acquainted with all the new products on the global construction market.

Buying foam blocks for building a house in our store is very profitable, because by doing so you reduce not only the time for building your home, but also the costs of building materials, labor, and in the future, heating the house, as well as additional sound insulation.

Living in a house made of foam plastic blocks is also very comfortable, because it is cool in the heat and warm in winter. And the construction of a house can not be postponed even in winter months, because low temperatures do not affect the properties of foam blocks. And you can build absolutely everything from blocks that can be built from bricks. But thanks to the plasticity of foam blocks, it is possible to realize various architectural fantasies, which cannot be done with brick. Therefore, the built house will be beautiful and at the same time cozy, standing out among standard buildings with its originality.

A modern home should not only be attractive and durable, but also economical and energy-saving. Therefore, lately, unconventional construction methods using materials that have not previously been used have become increasingly popular. One of the relative novelties in construction are the so-called thermal houses, the walls of which are erected from foam blocks filled with concrete.

Scheme of insulation of an expanded polystyrene facade.

Today, in order to build a warm and quality house, not only building materials such as brick, concrete or wood are used, but also polystyrene foam blocks, poured using ordinary solution made of concrete. Polystyrene foam, or polystyrene foam, long time was not considered as a full-fledged building material, but recently such designs have begun to be used more and more often.

How to build such a house? The technology itself is not very complicated, although it does require certain skills and time to build. Foam walls are erected using the following materials:

- Foam blocks, which have thick walls, are hollow inside. Blocks are produced only industrially.

- A concrete solution used to fill the cavities of blocks.

- Wooden formwork for blocks.

- Metal reinforcing bars that act as reinforcement when pouring wall blocks.

The construction process itself is as follows:

Scheme of attaching foam to the wall.

- First you need to install the foundation. IN in this case You can also use a strip one, but since the house is being poured from concrete, it is better to immediately calculate all the loads.

- After this, the laying of wall blocks begins, around which the wooden formwork. It is necessary to prevent deformation of the foam when pouring.

- The concrete is poured carefully; it is necessary to check that the blocks do not move or become deformed during the work.

Features of the thermal house

Why does a foam house stand out so much from the rest? The fact is that blocks made of foam plastic, or polystyrene, act as insulating formwork, which reduces heat loss. But it’s not enough to just order a house made of foam plastic; you need to plan it correctly. All windows of the house should be oriented to the south; it is recommended to create so-called buffer zones at the entrance. For houses that are built from blocks poured with concrete, you cannot skimp on doors and windows.

Among the features of such foam plastic buildings, it should be noted that they require the installation of a ventilation system and heating, that is, in the winter months such a house must be warmed up, although energy consumption will be minimal.

The people who put this warm house, but who neglected the rules for installing it (not so complicated), often complain about dampness and fungus that has appeared on the walls. But this is a consequence of a violation of technology, and not a defect in the material. Walls made of foam plastic and concrete are vapor-tight, so to maintain a comfortable atmosphere inside, a system should be installed forced ventilation. The best option is air handling units with recovery.

Finish options

The construction of foam plastic houses has its own characteristics, but one of the advantages over others should be noted that the walls in this case can be covered with almost any type of finishing materials.

Facade external walls, as a rule, are treated with a layer of decorative plaster, which is characterized by low cost and attractive appearance, but other options are also possible.

Scheme of thermal insulation of the foundation with polystyrene foam.

For example, you can use ventilated facade systems, which are not only attractive and give the building a modern, stylish look, but also provide an optimal microclimate in the house.

Interior walls can be finished with the most various materials. Today, they are most often sheathed with plasterboard, which provides many design options.

There are no restrictions on roofing materials for foam houses. Due to the fact that concrete mortar is poured inside the blocks, the house turns out to be virtually monolithic, capable of withstanding even heavy loads. That is, even natural materials can be laid on the roof surface. ceramic tiles, characterized by heavy weight.

In order not to spoil the interior decoration of the polystyrene foam house, everything engineering Communication can be laid directly in the walls of the house, but this must be done at the construction stage. The only difficulty is the use of only those materials that are acceptable for indoor installation.

Cons of construction

A lot has been said about the advantages and benefits of thermal houses, but is foam plastic really that good as a frame? And is it possible to avoid some of the disadvantages of such houses made of concrete and foam plastic? Let us consider the main difficulties and disadvantages that may arise during the construction and operation of such a structure.

Diagram of a polystyrene foam wall.

- Operational problems. This disadvantage is associated with the material itself - polystyrene foam. To attach shelves or cabinets to its surface, it is necessary to install special overlays during construction, which are fixed directly to the concrete. If this is not done, then when repairing or installing new furniture, you will have to cut the foam layer down to the concrete, and then attach wooden blocks to it, on which the cabinets will be hung. As you can see, this problem is solvable, although there is a certain inconvenience here, since additional, not the most simple, work is required.

- Heat capacity. Despite the fact that houses made of foam plastic are considered very warm, they still require winter time good warm-up.

- One of the main disadvantages of using concrete and foam plastic as building materials for walls is that the walls are vapor-tight. According to reviews from the owners of such houses, the atmosphere in them is always a little humid, which creates discomfort and is not the best pleasant microclimate. This problem can be solved, so it is not critical, but it requires some effort and expense. You can make the microclimate in your home more comfortable by installing coercive system ventilation. And taking into account the fact that such ventilation systems Today they are installed not only for foam houses, but also for many other buildings; such a drawback often goes simply unnoticed.

- Labor intensity. The construction of such a house requires certain efforts and skills. In this case, it is not just about installing blocks filled with concrete, it is necessary to install them correctly, in strict accordance with all technology requirements. But it cannot be said that installing foam blocks is more difficult than building a house, for example, from brick. In many cases, it is even easier to build such a house, although you will have to work hard when laying the first rows. The external and internal decoration of foam plastic walls requires effort and skill, as difficulties may arise during fastening. Therefore, it is necessary to use only special materials.

Many consider the disadvantages to be that the blocks are made of polystyrene foam. Not everyone prefers this material as the main material for building the walls of a house, but this is a rather controversial issue. The harm of polystyrene foam has not been proven; during operation it does not emit toxic substances, but it cannot be called natural either.

It is also necessary to note this point: today the number of houses built from foam plastic and concrete is not so large, that is, it is too early to talk about their advantages or obvious disadvantages over all others. These houses are stable and very comfortable, have an attractive price and the ability to host various shapes, but a more complete analysis of their operation still requires more than one year.

Construction requirements

A foam house today is one of the options for building housing quickly and inexpensively. This design can take on any, often very unexpected, but such attractive forms, which greatly distinguishes a thermal house from a traditional brick or wooden one. But if you have chosen just such a material, that is, blocks of foam plastic poured with concrete, you need to remember some features.

Diagram of an expanded polystyrene panel.

- transportation, unloading and installation of blocks must be careful, since the foam can be damaged at the ends, where the edges can chip. This problem can be solved by simply gluing the material, but this takes time, which makes installation longer;

- When purchasing, you should choose the right blocks, since unscrupulous manufacturers may make defects. All angles must be smooth, the dimensions must match the stated ones;

- When concrete is poured into blocks, not only the installation of formwork is required, but also constant checking of verticality using building level. This is necessary, since the foam expands when poured, that is, the blocks can move, but this should not be allowed;

- after the installation of the house structures is completed, you must immediately begin exterior decoration so that the foam comes into contact with direct sunlight as little as possible.

Today, not only are they used to build houses traditional materials, such as brick, wood, concrete and others, but also unusual at first glance, but no less high-quality and reliable. It's about about foam blocks, the cavities of which are filled inside concrete mixture. After hardening, the house takes on attractive shapes, it is durable, holds heat well, and is comfortable to live in.

Lately, one can increasingly hear talk about the so-called thermal house. It may seem like this is a made-up term from some science fiction novel, but in reality everything is much simpler. A thermal house is a house built from polystyrene foam. This technology construction is also called permanent formwork.

This article will discuss how to build a polystyrene foam house with your own hands.

Characteristics of foam blocks

These blocks are hollow boxes. Their dimensions are standard (95x25x25 cm), but for the construction of internal walls, products of a slightly smaller width are used - 95x13x25 cm.

Note! Expanded polystyrene blocks are produced using industrial conveyor production technology. During work shift The production line produces about one hundred and twenty blocks.

The advantages of building materials include:

- ease of processing and installation;

- resistance to permanent moisture;

- light weight;

- excellent noise insulation characteristics;

- high-quality thermal insulation due to the multilayer structure;

- resistance to rot and fungus.

It is also worth noting that polystyrene foam is a “breathable” material, that is, one that allows air to pass through.

But there are also disadvantages that need to be taken into account before construction begins.

- Foam blocks cannot withstand temperatures above 90? C.

- The strength of polystyrene foam is just an illusion; in fact, you can easily pierce it with your finger. In this regard, the walls will have to be puttied.

- The material is highly flammable.

The cost of one such block is approximately 300 rubles, which is relatively inexpensive. Let's consider the costs of building a polystyrene foam house in comparison with a brick one. Thus, a thermohouse is a structure that is ready for final finishing and can be covered with either plaster or paint, or siding. In the same time brick house needs putty and thermal insulation (with the same foam), which, of course, increases construction costs.

In a word, a thermal house is an inexpensive pleasure, since it already includes both finishing and insulation. Moreover, according to GOST, the height of such a house can reach 15 m, which is equivalent to 5-6 floors.

About the environmental friendliness of the material

Most people are sure that polystyrene foam, like any other “chemical”, is unsafe or even harmful to health. This fact has not yet been confirmed, but it has not been refuted either. It is worth noting that there are a number of requirements, in particular sanitary and GOST, to which the manufactured products fully comply.

But some people are difficult to convince even of obvious things, which is most likely due to a psychological factor. And even the fact that polystyrene foam is widely used in insulation and interior decoration, as well as in the manufacture of disposable tableware, for some reason is not a compelling argument in this case.

Foam house: construction instructions

Having dealt with the strong and weaknesses material, you can begin installation. But first you need to prepare everything you need.

Stage 1. Tools, materials

The work will require:

- foam blocks;

- finishing material;

- sand;

- wires, pipes;

- metal fittings o12 mm;

- steel wire for the bundle;

- “six hundredth” grade cement;

- water;

- crushed stone;

- concrete mixer.

Stage 2. Foundation

Construction of a house begins with the foundation. The best option- an ordinary strip foundation, although everything depends on the characteristics of the soil in the selected region.

After pouring, the base is supplemented with support. To do this, wooden blocks measuring 50x60 mm are laid along the entire perimeter of the foundation. The entire remaining area must be laid with boards of similar thickness.

Note! After laying, the wood is treated with a fire retardant and antiseptic.

Stage 3. Assembling the structure

The construction of a thermal house is similar to the assembly of a construction set - the blocks are joined groove to groove, laid with reinforcement and assembled into walls.

Step 1. Foam blocks are prepared for installation: cleaned, leveled and thoroughly dried.

Step 3. Concrete solution is prepared. To do this, cement, crushed stone and sand are poured into a concrete mixer in a ratio of 1:3:3 and filled with such an amount of water that the resulting liquid mixture is obtained.

Step 4. After running five rows, the solution is poured into the voids between the layers of blocks. When pouring, it is advisable to tap the side surface of each block - this will make the concrete shrink more densely.

Step 5. Part of the wall is assembled from the next five rows of blocks and filled with mortar again. The procedure is repeated until construction is completed.

Step 6. Sewage, wiring and other communications are laid directly into the walls of the house, after which it is covered with a roof and the final finishing of the walls is carried out. It is typical that it is recommended to lay the pipeline in still hollow walls, while the electrical wiring is routed through pre-made grooves (there should be no problems with grooved foam).

In choise roofing material there are also no restrictions. In essence, a foam house - monolithic design, capable of withstanding any load, so even natural tiles can be used for coating.

Note! It is better to start the construction of a thermal house in the warm season at a temperature not lower than -10? C.

Foam blocks retain their original properties for a long time. There is even an opinion that a house built from these blocks, under appropriate conditions, can last up to 100 years.

Stage 4. Finishing

As already mentioned, there are practically no restrictions when decorating the walls of a thermal house internally/externally. From a financial point of view, it is more profitable to use decorative plaster or regular paint, and cover the inside with plasterboard.

The thermohome may look different. Below are instructions for constructing an arched building standard sizes: the height of the walls is 3 m, total area– about 10 m?. Of course, as a permanent home similar design cannot be used.

What will be required at work

Before starting construction, you need to take care of everything necessary. Below is a list of materials:

- foam blocks;

- building level;

- concrete solution;

- polyurethane foam;

- dowels, screws;

- ruler;

- marker.

Construction technology

Step 1. First, the foundation is built. In this case there are no differences from previous version No.

Step 2. A 50x60 mm beam is laid along the entire perimeter of the base, fastening is done using anchors. In this case, the structure is periodically checked with a level.

Note! To optimize fastening, you can use any mounting foam, except extra-class. This is explained simply: this type of foam expands greatly.

Step 3. Side walls bases protruding above the ground are trimmed decorative stone. The stone is placed on ordinary concrete mortar and lightly knocked down with a hammer.

Step 4. The foundation is covered with a waterproofing layer (suitable polyethylene film). A brick can be laid on top of the film to increase the strength of the foundation and protect against subsidence.

Step 5. Next, foam blocks are prepared. They are cut and glued in accordance with preliminary measurements. For the frame of the arch you need to use only shaped blocks, and to fill the walls you can use ordinary thick sheets. Polyurethane foam is used for gluing.

Note! For fixation, you can use special glue for polystyrene foam, but polyurethane foam is consumed more economically. The only drawback of foam is that its expansion must be constantly monitored, otherwise the tightness of the frame may be compromised.

Step 6. Ready arches made of foam plastic are attached to the base with self-tapping screws and dowels. To do this, holes are made along the entire perimeter of the foundation (with equal spacing), into which high self-tapping screws are installed. Then, holes are made in the appropriate places in the lower part of each arch, after which the arches are mounted on self-tapping screws.

Note! For ease of assembly, dowels can be inserted into the holes in the arches in advance.

Step 7. The arches are additionally fixed. If polyurethane foam is used, then it fills the gap between the frame and the base using a thin tube. If glue is used, then all working surfaces are lubricated with it before installing the arches.

Step 8. All that remains is to seal the cracks between the blocks concrete mortar and plaster the walls of the house. For further finishing, as already mentioned, you can use any material - it all depends on financial capabilities and personal preferences.

As you can see, building a foam house is not such a complicated procedure. The main thing is to correctly calculate the consumption of building materials and securely fix the blocks on the foundation. By the way, not only blocks can be used in construction.

Finally. Perforated polystyrene foam panels

For permanent formwork You can use not only foam blocks, but also large perforated panels that are connected to each other by a frame made of reinforcement. The panels are attached to the reinforcement using mushroom-shaped nuts at the perforation points (such nuts are made from polyethylene under high pressure).

The average size of each panel is 100x300 cm. The gap between the outer and internal slabs(each 5 cm thick) is 15 cm, which is quite enough to build a house of two or three floors. Products are delivered to construction site element by element or ready-made.

Video - Building a house from foam blocks

Expanded polystyrene blocks are the result of the efforts of scientists from the German chemical company BASF, who tried to combine various properties and characteristics.

Light and warm blocks made of foamed polystyrene foam for home use today are actively used in modern construction. We invite you to familiarize yourself with basic information about the material - its characteristics, dimensions, pros and cons of use - in this article.

Main characteristics of polystyrene foam blocks

Despite the fact that the first blocks of foamed polystyrene foam appeared back in the 70s in the USSR, developers only recently began to actively pay attention to this building material.

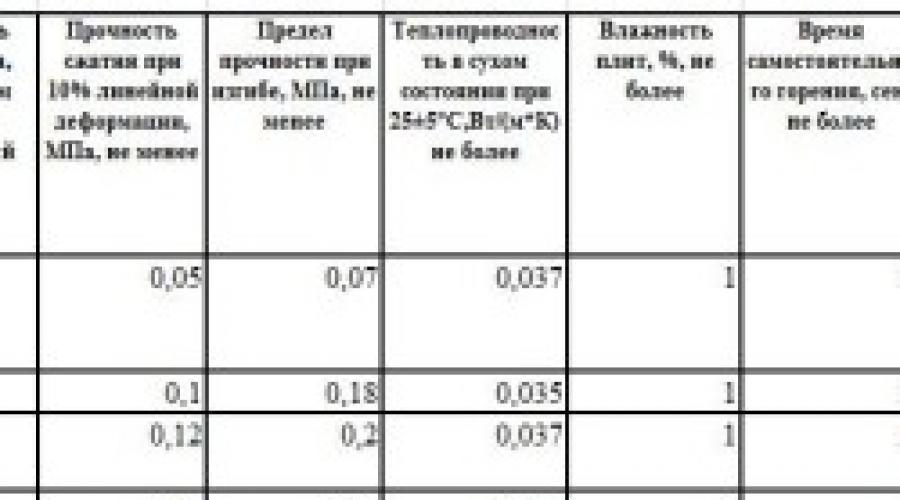

The production of polystyrene foam blocks is now established on an industrial scale at many domestic enterprises. Below are basic physical properties blocks, standardized by GOST:

- the density of blocks for a house should be from 150 to 800 kg/m³;

- have good resistance to frost (without loss of properties, the block will last from 30 to 150 cycles of freezing and thawing);

- the compressive strength indicator ranges from B0.35 to B2.5;

- The thermal conductivity index varies from 0.055 W/mºC to 0.145 W/mºC;

- vapor permeability coefficient is 0.05 mg;

- The material belongs to the low-flammability group, that is, it is fire resistant.

1.1 Application of material

The use of building materials is allowed for:

- construction of external walls of buildings;

- arrangement interior partitions on upper floors houses in which, as a result of the weakness of the slabs, the use of cinder blocks or other heavy materials impossible;

- as an additional insulation or soundproofing layer in a building;

- when constructing premises that require maintaining a certain temperature level, for example, for the construction of a bathhouse or a pen for animals.

1.2 Advantages and disadvantages

Having analyzed these characteristics, we will consider the pros and cons of the material for building a house. Based on GOST standards, one can assume that all the characteristics of expanded polystyrene concrete are normal and it is quite possible to build large buildings from it, but this is not the case.

For example, the compressive strength of blocks is not particularly high; therefore, experts strongly do not recommend building a house with a height of more than two floors from this building material.

A small coefficient of vapor permeability also has its pros and cons. The advantages are that the material does not absorb moisture, which means it resists frost well. But the disadvantages are that this same property does not allow the building material to “breathe”. As for the environmental properties of the blocks, everything here is also not clear.

You can definitely say something about environmental friendliness only after many years of living in a house built from expanded polystyrene. This is only possible by analyzing the air to detect styrene, but no one is doing this today.

Today, consumers have only one proof - certificates received by the manufacturer, the authenticity of which, unfortunately, cannot be determined.

The undoubted advantage is that expanded polystyrene concrete has a long service life. Considering these advantages, many developers today choose this material for the construction of one- and two-story houses.

If you believe the reviews of experts, the disadvantages of houses built from expanded polystyrene concrete include the possibility of destruction of the material from constant sun rays. In addition, according to data posted on construction forums, polystyrene foam is not recommended for use in internal insulation.

Despite all the disadvantages, the building material is still has three main advantages:

- Excellent energy-saving properties, as a result of which the owner of the house does not need to additional insulation building.

- Expanded polystyrene concrete does not need waterproofing.

- Plasticity of the material and precise dimensional geometry. As a result, installation is greatly simplified, which helps save mortar.

1.3 Polystyrene concrete blocks: disadvantages and advantages (video)

1.4 Dimensions and approximate cost

Today you can find blocks in many sizes on sale. The most popular sizes that are in demand among consumers are the following (based on width-height-length):

- 188x300x588;

- 300x380x588;

- 92x300x588;

- 138×300588;

- 80x300x600 (can only be used when building interior partitions).

Also on sale you can find polystyrene foam blocks in high density(about 600 kg/m³), which are lintels for doors or windows. Such blocks are reinforced and are intended for both load-bearing and heat-insulating structures.

Now regarding the cost. Of course, we cannot provide exact prices as they change from time to time. But the approximate price range is: price for cubic meter polystyrene concrete blocks vary around 3,500 rubles (1,200 hryvnia). Cost foam concrete material approximately the same.

When compared with aerated concrete, the latter costs about 3,800 rubles (1,300 hryvnia) per cubic meter, and wood concrete costs around 4,500 rubles (1,500 hryvnia).

2 Production technology

Let's briefly consider the manufacturing technology of building materials. To obtain the final product, manufacturers use the pressing method, which, in fact, is used to produce all blocks used in construction without exception.

More modernized production uses the method of vibratory pressing of blocks. According to experts, this makes it possible to improve the stability indicator and also increase the service life.

If you understand that insulating a concrete floor with polystyrene foam is a profitable business, then You can try to organize your business at home. To organize production, you will need a concrete mixer, the polystyrene material itself, cement, water and sand.

Naturally, the volumes of sand, cement and water must be quite large. At home, it is quite possible to make building materials with a density of D1200 and D350. To produce the first one you will need:

- 1.1 cubic meter of polystyrene foam;

- about 300 kg of cement;

- approximately 800 kg of sand.

When the mixture hardens, the result will be you will get solid concrete material. The production stages are as follows:

- First you need to make the mixture. The elements described above must be mixed in a concrete mixer for about thirty minutes.

- Then the mixture is poured into formwork or pre-prepared forms.

- IN summer time During the year it will take about three days for the mixture to harden; in winter - at least a week, sometimes more. In any case, before removing the resulting polystyrene foam from the molds, it must harden.

- The next stage, at your discretion, is cutting the material.