House made of timber 140x140 for winter. Does a timber house freeze in winter? What kind of timber to build a “winter” house from?

This question, to be honest, is somewhat incorrect. The fact is that profiled timber can withstand any temperature, both -30 * C and -50 * C, but the only question is how much heat is required for this? Therefore, speaking about the maximum external temperatures for profiled timber, one should consider optimal ratio between permissible heat losses, the required temperature in the house and the total thermal resistance of the timber wall, which depends on the thickness of the material, its physical characteristics and quality.

Does the thickness of the wall of a timber house matter?

If the walls are not additionally insulated, then of course they are. As mentioned above, the main indicator that determines the preservation of heat in the house is thermal resistance timber walls. Depending on the thickness of the material, this value has the following values:

– for timber 100 mm thick – 0.55 m2 x *C / W;

– for timber 150 mm thick – 0.83 m2 x *C / W;

– for timber 200 mm thick – 1.09 m2 x *C / W.

As you can see, the thicker the wall, the greater its thermal resistance, which means less heat is lost. Resistance 0.83 m2 x *C / W provides permissible value heat losses through the building envelope in a temperate climate zone, can provide comfortable conditions for living in a house. Based on the requirements of building codes, to ensure economical operation of the heating system at a temperature of –30*C it is required minimum thickness timber is 380 mm, and rounded logs are more than half a meter. These values were obtained by calculation, which took into account the position of the dew point inside the walls, the minimum permissible heat loss and ordinary (i.e. poor quality) material.

What temperatures can timber of different sections withstand?

Of course, no one uses timber with a cross-section of more than 380 mm and logs half a meter thick when building a house, since they simply are not on sale, and as practice shows, profiled timber with a cross-section of 150 x 150 mm, without additional thermal insulation, completely provides comfortable conditions for outside temperature air down to –26*C. Beam with a section of 100 x 150 mm, at an external air temperature of up to –19*C, and with a cross-section of 200 x 150 at a temperature of up to –31*C. This difference between theoretical calculation data and practical indicators is ensured by high quality modern materials and improved technologies for building houses from profiled timber. And the use of additional thermal insulation with a thickness of only 100 mm, when fixed to the outer surface of the wall, increases the thermal resistance of the structure by 2-3 times, correspondingly increasing the temperature limits. And then, the thickness of the wall can only be calculated as load-bearing structure, selecting the required thickness of thermal insulation to reduce heat loss through it.

What thickness of timber wall should I choose for permanent residence?

Thickness of a wall made of profiled timber in a house for permanent residence determined by the climatic region where the house is built, the average and lowest outdoor temperatures in winter period. For a temperate climate with a design temperature from –24*C to –28*C, you can use profiled timber with a section of 150-150 mm or 150 x 200 mm, providing a wall thickness of 150 mm. At lower temperatures, 200 mm thick timber should be used for construction. Or use extra outer layer thermal insulation.

Can a log house withstand strong winds?

Of course it can withstand it, since the technology for assembling such a house involves connecting the rows to each other using special dowels, as well as reinforced fastenings at the corners of the building and at the junction of internal walls. The bottom row of beams is attached to the foundation using embedded parts, the threaded rods of which pass through the beam right through. A house assembled in this way for shrinkage is very strong, so even very strong wind he is not afraid. Modern technology construction of houses from construction wood guarantees them high quality and strength.

When building your own wooden house Every person asks the question: “How to choose the optimal thickness of timber for internal and external walls”? Our article will help you understand what types and sizes of this material there are, how to correctly calculate its thickness and understand for yourself what required thickness timber for a timber house in your case.

Types and sizes of wood for building houses

There are three types of timber for building houses.

- Planed profiled and non-profiled;

- Glued.

A round log is actually a log, from which the bark and upper layer tree.

The diameter of the log is the same along its entire length, which greatly facilitates the construction of the house.

The disadvantages include:

- high shrinkage of the log house (up to 10%);

- the formation of cracks is also possible, especially in the corners of the frame and joints, which is unacceptable;

- in addition, such a log house has high ventilation;

- very vulnerable to damage by fungus and mold;

- due to low manufacturing accuracy and high shrinkage, additional caulking of the seams is usually required after complete drying.

It is made at the factory from wood with a residual moisture content of no more than 30%. To do this, the log is sawn to the required size.

Standard beam sections:

- 150x150,

- 150x200,

- 200x200 mm.

Its undeniable advantage compared to round timber is the absence of excess wood, which means the house requires a less massive foundation. In addition from rectangular timber building is much more convenient and, therefore, faster.

The disadvantages are the same as those of round timber, except for high shrinkage.

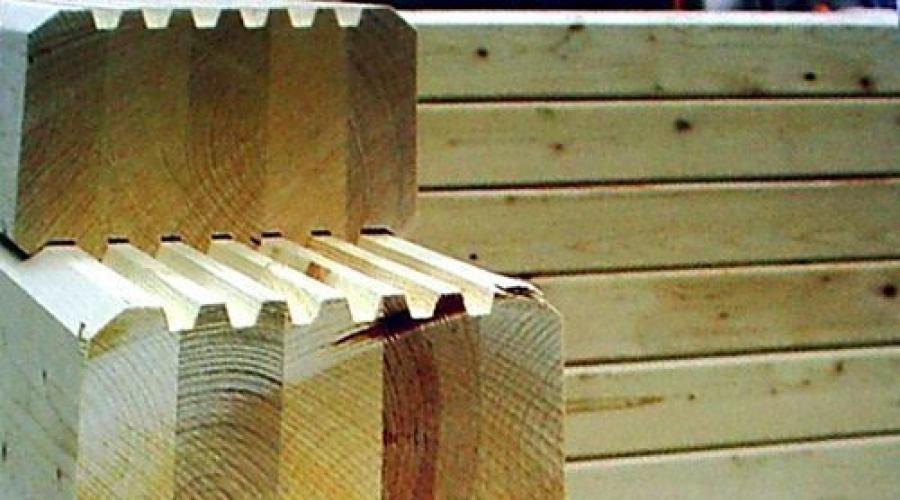

Profiled timber is distinguished by the fact that grooves are selected from opposite sides at the factory in such a way that during assembly the structure is assembled using the tongue-and-groove method.

This creates a very precise connection that is practically not blown by the wind. The disadvantages remain the same, except for airflow.

Glued laminated timber is already a new technology in production wooden beam for construction. It is devoid of all the disadvantages inherent in all previous types of material.

Timber is made from boards dried to relative humidity 2-10% and glued under high pressure in the package. After gluing, the finished package is profiled.

Due to the layered structure it:

- does not warp;

- does not crack;

- does not dry out.

Since during the gluing process the boards are treated with special antifungal compounds, laminated veneer lumber does not mold or rot. – significantly higher price.

Ready-made kits for assembly

Many factories for the production of laminated veneer lumber produce special kits wooden houses to build with your own hands. Everything is included in the package necessary elements with ready-made cuts for connecting to each other.

All elements must be marked. From such a kit the house is built like a construction set.

The maximum thickness of laminated veneer lumber is determined both by GOST standards and by the equipment on which it is produced. Typically, material for walls is made up to 9 m long with thicknesses from 210 to 270 mm and a height of up to 270 mm.

Rafters and floor beams are manufactured with a length of up to 12 m and a cross-section of up to 50x100 mm. It must be said that there are other sizes.

The kit for building a wooden house is manufactured at the factory according to individual orders.

The package may include:

- seal made of special non-woven fabric, which is not subject to rotting and decay to ensure the tightness of the walls of the house;

- or timber with wedge-shaped grooves and protrusions to ensure the tightness of the connection;

- tie rods and brackets;

- compression springs with a force of up to 2000 kg each, so that during operation the wood does not warp and gaps do not appear as it shrinks;

- assembly drawings and instructions for assembling a house with your own hands;

- specification of materials included;

- manufacturer's warranty;

- certificates of quality and environmental conformity;

- 3D models of a finished house.

How to choose the optimal timber thickness for your home

According to building regulations and rules (SNiP), the thickness of the timber for a house is selected depending on the climate of the area where the house is planned to be built. However, it must be said that there are some calculations by which it is possible to establish exact value this parameter.

Calculation formulas

The thickness of the walls of the house is selected in this case according to two main criteria:

- sanitary and hygienic (standardized);

- energy saving.

The required size for walls can be calculated using the formula:

Sm = R * Kt;

where Sm is the required thickness of the material,

R – heat transfer resistance of the wall (depending on the region of residence),

Kt is the thermal conductivity coefficient of the material.

For middle zone The heat transfer resistance of the wall is assumed to be 3.0 - 3.2. Kt for wood 0.12-0.18 depending on the type of wood. For a specific region, this value can be found in the corresponding directory.

Thus, we get for a house built from pine timber:

Sm = 3.0*0.15 = 0.45m

Those. The thickness of the timber for construction should be 450 mm. In practice, material with such dimensions is not produced. In order to maintain a comfortable temperature in the room, it is necessary to insulate the walls from the inside. To insulate walls both inside and outside, imitation timber is used, under which a layer of insulation based on mineral wool is laid.

Advice! In practice, according to experts, with a wall beam thickness of 150 mm, 100 mm thick insulation is sufficient, and if the timber is 200 mm thick, then 50 mm of insulation is sufficient.

Wall insulation

In order to make living comfortable, imitation timber is used to insulate the walls both inside and outside. Due to the variety of shapes and sizes of this lumber, everyone can choose it to their liking.

Exterior decoration

- Standard length of simulation is 3 and 6 m. There are also sizes 2, 2.2, 3.6, 5.4 m.

- The thickness of the imitation timber ranges from 18 to 34 mm. The width of the lamellas is from 110 to 190 mm.

- In practice, for exterior finishing, a material with a width of 150 mm and a thickness of 25-32 mm is used in order to achieve maximum similarity of the finish to natural material.

- If you use a narrower imitation of timber, the wall will resemble a wall covered with clapboard, and therefore there is no point in overpaying.

In order to achieve minimum quantity joints at exterior decoration The length of the lamellas should be selected greater than the length of the wall.

To prevent a wall finished with imitation timber from warping over time, to select the thickness of the imitation timber, you should use SNiP, which regulates the ratio of the width of the lamellas and their thickness according to the formula:

T=W/5.5,

where T is the thickness of the lamella, and W is its width.

Advice! When laying insulation outside wooden wall a vapor barrier layer should be installed on both sides of the insulation. This is necessary in order to prevent moisture from entering both inside and outside.

Interior decoration

For interior decoration premises, it is advisable to use imitation with a width of less than 110 mm. This is due to the fact that the wider the lamella, the optically smaller sizes the room being finished. In addition, the thickness of the imitation timber in this case can be significantly less than for exterior finishing, and therefore cheaper.

The product is often mounted indoors in different directions, which allows you to choose its optimal length. Usually take a length of 2 or 3 m. With such lengths, among other things, it is much more convenient to work indoors.

Particular attention should be paid to the ceiling decoration. On the ceiling, the joints of the lamellas are clearly visible. Therefore, for the ceiling lining, you should either use imitation timber for the entire length of the room or join it using the parquet method, alternating the junction of the lamellas with the middle of the next one.

Conclusion

It becomes clear that the process has its own nuances and some subtleties associated with calculations, including the calculation of the optimal thickness of the material. Of course, this work is not the most difficult, but it also requires detailed consideration.

And the video in this article will help you understand some other points.

The beam cross-section is insufficient for the climate of the central zone of the Russian Federation (without additional insulation and façade cladding, respectively) will force the heating boiler to operate in locomotive mode. Limited financial resources for construction + influence (wife, mother-in-law) on the decision to save on thickness guarantees poor sound insulation and high costs for maintaining the house.

The optimal thickness of the walls (width of the timber) means you can avoid wasting money on useless heating of the street. Depending on the profile height, equipment features profiled timber or laminated veneer lumber must be at least 190-200mm wide.

IN wooden house, for visits only on weekends in winter, in the absence of people, it is imperative to maintain a temperature of +10-12Cº. Otherwise, after freezing/thawing, the tree will begin to crack. Upon arrival, heat until comfortable temperature and then maintaining it in timber from 190mm will not be difficult. For gardening summer house 140 or 150mm is enough. For a bathhouse, such a section of timber is theoretically enough, but it is better to cut down a Russian bathhouse. The timber cracks quickly and twists strongly in the wall due to changes in humidity.

The ratio of the width and height of the beam profile has a slight effect on heat loss. Many people are more concerned about the natural cracking that is inevitable when solid wood dries out. Which, contrary to popular belief, chamber drying does not eliminate 100%. Therefore, profiled timber is often given unequal dimensions: the width is greater than the height. Cracks form more intensively on a wider surface and will go deeper into the wall. On visible outer surface(on the short side) there will be few of them.

Most owners timber houses with a wall thickness of 140-150mm, they must understand the inevitability of additional insulation from the facade subsequently. If the house is a permanent residence, the process of throwing money into the firebox can become tiresome after the first heating session. Insulation is done from the outside: the closer the insulation is located to cold side walls. Plus a shift in the “dew point” towards the street.

U houses made of simple timber as opposed to profiled The façade cladding also protects flat joints without a profile lock from water ingress and wind blowing. The most reliable and beautiful lining facade - facing brick. The house looks rich and is well protected from the weather. But the final investment is several times higher than the cost of the additional width of the beam, which is sufficient in terms of heat.

Interesting fact: after cladding timber walls brick, heating intensity does not decrease. This is due to excessive humidity of solid wood due to the lack of possibility of unhindered removal of moisture from interior spaces beyond the wooden walls. The thermal characteristics of the timber deteriorate. The overall thickness of the wall is large, and heating bills are rising.

Balance between cost wall material/ heating costs over the years justify an increase in wall thickness to 190-200mm. You need to understand: the cost of solid wood walls is only 1/4 of general estimate for construction(foundation, roof, communications, finishing). If financial capabilities allow, thicker is always better (warmer). The total heat loss at home also depends on professional assembly; quality of insulation of the attic, floors, ceilings; glazing area.

Large heating costs in winter, due to savings on the cross-section of timber, will gradually negate all the initial benefits. The intense heating makes the expensive wood dark and crack. If you try to preserve the beauty of the array in this case, you will have to sacrifice something, although physically it itself tolerates low air temperatures calmly. Turn down the heating and you will sacrifice human health.

Many believe that the thicker the timber, the better it is suitable for building a house for year-round residence. For such a cottage, it is recommended to choose materials with a cross-section of at least 150x150. But that's not true. On thermal insulation properties influence insulation, window finishing and doorways. The vestibule and hallway will help insulate the room. In this case, you can use timber with smaller parameters.

At “MariSrub” you can order the construction of a house from timber with a cross-section of 140x140 mm. We provide high-quality and reliable finishing and insulation. We use only durable and proven materials. When you order construction from “MariSrub” you will receive warm and cozy housing, which is comfortable both in summer and winter.

The timber is characterized by environmental friendliness, durability and attractive appearance. Houses made of timber look elegant, stylish and graceful. They will stand out favorably against the background of other buildings. The timber is easy to process and lay. You will achieve any architectural forms.

Houses made of timber from the manufacturer

“MariSrub” craftsmen procure raw materials, dry them and produce lumber themselves. We use the latest safe technologies, which preserve the natural properties of wood, reduce the amount of defects and enhance operational properties products.

We offer construction country house from profiled timber. These are environmentally friendly and non-toxic materials of the correct geometric shape, which are easy to install. Installation of a wall kit takes one to two weeks, and construction of a turnkey house will take two to three months.

We organize turnkey construction, which includes the design and production of lumber for the project, construction of the foundation and roof, installation of the log house and finishing. We carry out work on insulating the walls of the house and install communication systems.

We treat wood with antiseptics and other protective equipment in several stages. This will prevent the appearance of cracks, rot and mold on the materials, and will increase the service life of the materials.

We build houses according to ready-made and individual designs. The firm's architect will competently and rationally draw up a project and plan the space of the house. Ideal for permanent residence two-story cottages and houses with an attic with an area of over 100-150 square meters. Projects with terraces and balconies are in demand.

Advantages of “MariSrub”

- Own production and work without intermediaries;

- To produce lumber, we use sustainable winter wood, which undergoes careful selection and safe processing;

- When installing a log house and making timber, we process natural wood protective equipment;

- Affordable prices for timber;

- High quality lumber;

- Creation individual project and construction using ready-made options;

- Staged payment;

- Fixed cost and clear budgeting;

- Shrinkage warranty - one year;

- Free design when ordering turnkey construction.

At the MariSrub company you can order the construction of a house from 140x140 timber from the manufacturer. We offer a full range of works that are needed to build a cottage for permanent residence.