Do-it-yourself wooden steps to the porch: calculating the steps. How to build a porch made of wood - a beautiful and functional addition to the entrance to the house Making steps for the porch

It is impossible to imagine a building without an entrance. Any building requires a convenient and practical entrance.

The porch can have a different design, and different materials are used, but all entrance steps have something in common. What should definitely be taken into account when designing the dimensions of the porch is GOST. Moreover, depending on the material, the optimal dimensions of the porch steps are calculated using various standards.

Below we will describe how to correctly calculate the sizes of the elements of the entrance group using simple formulas; We’ll tell you what established construction standards and technical conditions should be relied upon when designing and building an entrance staircase with your own hands; and how to avoid common mistakes and unplanned expenses.

Before we figure out what the size of the porch of a private house should be, let’s consider what parts this structure consists of.

The main elements of the entrance group are:

- steps, which in turn consist of treads and risers;

- area in front of the front door;

- fencing of staircases and landings;

Before calculating the size of the porch, you should decide on the main functions of this object. If the staircase will be the main entrance to the house, then this sets certain design requirements. At the same time, when designing additional, economic approaches to the house, the available capabilities are taken into account rather than the necessary requirements.

Dimensions of the entrance staircase

Regardless of the finish, the entrance group, which will serve the main entrance to the house, must be comfortable, practical and safe. These requirements are not vague, but have very specific physical indicators.

- In order for the staircase to be comfortable for use, before designing the structure, you should familiarize yourself with some construction GOSTs:

- 9818 - 2015 “Marches and platforms of reinforced concrete stairs”

- 23120 - 78 “Steel staircases, platforms and fencing”

- 25772 - 83 “Steel fencing for stairs, balconies and roofs”

- Of course, you should rely on the document that describes structures made from the corresponding material. In addition, the specified GOSTs provide a list of regulatory documents required for review.

- If you are not ready to approach this issue responsibly, then you should abandon the idea of designing it yourself and trust the professionals. Let's try to simplify the task somewhat and write down the main parameters of the porch stairs that should be observed.

steps

As mentioned above, steps have 2 elements:

- tread- horizontal surface (step width);

- riser- vertical part (step height).

On a note! Sometimes, during construction, the vertical part of the step may be open, which is also acceptable when constructing an entrance porch.

There is no such thing as a standard porch step size. There are recommended size ranges, and the calculation of specific structures is always done individually.

The size of the porch steps will depend on:

- span inclination angle;

- staircase construction material;

- way .

Important! When designing, you should take into account the height of the base, which affects the size of the steps for the porch and the slope of the flight of stairs.

Height calculation

According to building codes and regulations, the vertical size of steps for the porch of a house should be in the range from 13 to 20 cm.

- The ideal step height is considered to be in the range of 14 - 18 cm. Specifically for the entrance group, this parameter is determined based on the height of the residents.

- It should be borne in mind that for small children and elderly people, using steps with a high height is quite difficult.

Important! Regardless of the selected tread size, this parameter should be the same throughout the entire flight of stairs.

- The height of the steps may be influenced by the fact that the march must adhere to the rule of an odd number of steps. That is, in order for the movement on the stairs to be comfortable, the ascent or descent must begin and end with one foot.

Therefore, having determined the total height of the porch, it is recommended to divide it into an odd number of steps.

Step width

The size of the tread is directly dependent on the height of the riser. The main criterion for a correctly selected width is the fact that a person’s foot must completely fit on the tiled step. Typically this size is in the range of 25-30 cm.

Changing the overall height of the porch seems quite problematic, but changing the angle of inclination by changing the length of the flight of stairs is not so difficult. What size are the steps for the porch? To make the staircase practical and comfortable, use formulas when calculating.

Safety and convenience

In practice, the size of steps for a porch can be calculated using several formulas.

- More often than others, the so-called “convenience formula” is used: 2H+B=S, where:

- H - riser size (vertical);

- B - tread size (horizontal);

- S is the average step length of a person, usually equal to 63±3 cm.

- This formula takes into account the length of the average step, which is quite important in a situation where the residents of the house have different heights and ages, as a rule, in families where three generations live together.

- If you are building a house where this parameter is not so important, you can calculate the dimensions of the steps for the porch - the dimensions of the tread and riser, using a simpler formula: B-H = 12. This dependence was derived empirically by specialists from the Institute of Psychology. As we can see, this formula does not take into account the difference in the size of the average step.

- There is also a safety formula that determines the dimensions of the steps not from the point of view of comfort, but from the point of view of reliability of movement. That is, the situation in which the foot will not slip off the tread is being calculated. According to this formula, the sum of the size of the tread and riser should be 45 - 47 cm. That is, B + H = 46 ± 1 cm.

What is a porch, why does it exist and what functions does it perform?

The porch is an extension to the house, which, through steps, makes it easier to enter/exit the doors. Since the porch usually has a canopy, this provides additional protection for the doorway from the sun, rain and snow.

In addition, the porch acts as a decorative element that makes the exterior of the house complete and makes its operation convenient.

As a rule, the parameters of the porch are thought out at the stage of building a house, cottage or cottage. But often a porch is attached to an existing structure.

Traditionally, to build a porch in front of a house, the same material from which it is built is used (for example, a wooden or brick house). The porch can be made of wood, concrete, metal, brick. It is important that the selected material (for steps, cladding, porch finishing) is in harmony with the overall design of the house.

Due to the fact that wood is the most popular, as well as accessible and inexpensive material, porches are most often built from wood. Therefore, we will consider in detail (step by step) how to organize the construction of a wooden porch. Another argument in favor of lumber is the ease of working with wood, which makes it possible to make a wooden porch with your own hands.

Wooden porch for a private house - project

Construction begins with the development of a project that takes into account:

Types of porch

Porch design

- built-in porch - built together with the house, has a common foundation with it;

- attached (attached porch) - completed during the operation of the house.

Material for porches in a private house

- tree;

- concrete;

- metal (forging, steel, iron);

- brick (stone).

Methods for constructing a wooden porch

Possible implementation in two versions:

This method is simpler and consists in installing a wooden box (or a porch frame made of a metal profile) on the prepared site, on which steps are installed.

This option is also more budget-friendly; it can be implemented at any stage of construction or operation of the house. A closed wooden porch makes it possible to hide all the flaws that arise during the construction stage;

The peculiarity of this method is that the base frame is prepared only for the lower part of the stringer/string, and the upper one rests on beams or a floor slab. This method of building a porch provides more opportunities for implementing original solutions.

How to make a wooden porch with your own hands without mistakes

Before we tell you how to build a wooden porch, we will describe the main mistakes that novice craftsmen may encounter.

- stylistic errors. The dimensions, appearance, and material of the porch must be in harmony with the general appearance of the building (house design);

- errors in the dimensions of the porch. The porch should be proportional to the main building;

- errors in measurements. Each parameter is measured several times and plotted on the diagram;>

Note. Professionals advise putting on the diagram not only the dimensions of the porch and wooden frame, but also other parameters: the size of the doorway, the distance from the porch to the plants or protruding decorative elements. This information will be useful if necessary to correct the porch drawing.

- excess material consumption. Eliminated through careful planning.

- ignoring the requirements for structural strength. The porch is the most used part of the building. In addition, it is exposed to external factors, which means the material must be selected with a margin of safety and taking into account the dimensions of the porch;

- provide additional protection to a wooden porch. Untreated wood gradually loses its properties, so it needs protection and constant care;

Note. Both open parts of the structure and load-bearing parts need protection, i.e. those that are placed in the ground or rest on a foundation.

- separation of the foundations of the house and the porch (on different (separate) foundations) will lead to uneven shrinkage of the porch and the appearance of a crack between the elements. This can be avoided by a threshold installed at the junction of the porch and the house. Or installing a threshold without a march, with the first step 150-170 mm below the threshold. But this is fraught with injury, since when leaving the door, the user is forced to go down;

- the absence of a foundation leads to the fact that the porch “floats” under the influence of soil displacement (shear);

- jamming of doors (blocking, jamming). Occurs due to geological changes (frozen soil can raise the porch a couple of centimeters).

How to properly build a porch for a house

Material for making a porch

To make a beautiful wooden porch you will need building materials:

- For supports, a beam with a cross section of 100x200 mm is suitable. The size depends on the type of porch, the expected load, the number of supports, etc. When choosing wood for supports, it is better to give preference to larch or pine, due to the presence of resins, they can withstand all-season operating conditions well;

- for the entrance platform from the steps you can use a board 30-50 mm thick;

- ready-made balusters and railings. Or timber and lath for their manufacture. The dimensions of the lumber depend on the parameters of the future product.

- solutions, compositions and impregnations for wood protection;

- cement mortar (concrete);

Note. Using 50 mm boards for both supports and steps will allow you to avoid errors in calculations, reduce waste and, in general, use lumber more efficiently.

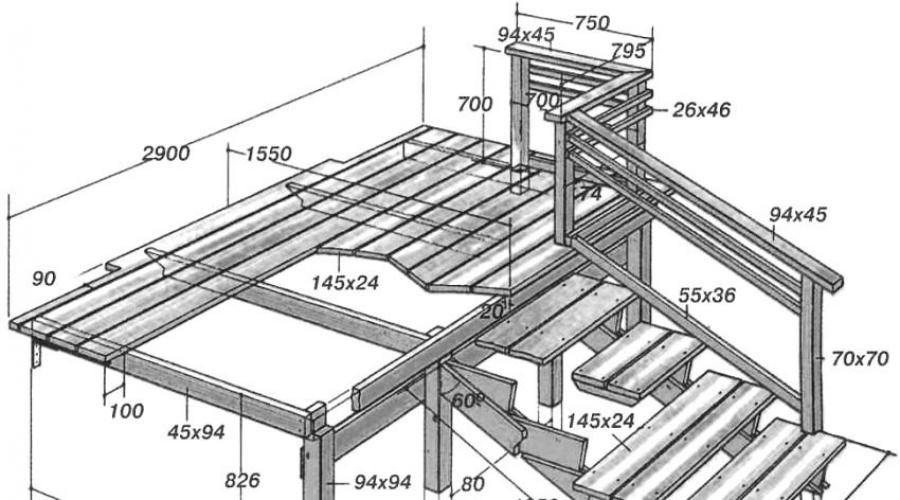

Drawing of a wooden porch

Even a simple (standard) drawing, drawn independently, will help to avoid difficulties during its construction.

The porch drawing must contain the following information:

- appearance of the porch. Makes it possible to visualize the final appearance of the structure;

- the width of the porch should be one and a half times wider than the doorway (you can calculate how wide the porch should be this way: 1.5 times the width of the door, this will be the minimum allowable width). This width will allow you to open the door while on the porch area;

- The width of the stairs to the porch (flight of stairs) must be at least 700 mm. Otherwise, difficulties will arise when moving people and objects along the steps;

- location of the porch platform (flooring). The porch floor should be 30-50 mm below the threshold (doorway). A lowered porch platform will prevent the doors from blocking due to snow or lifting of the porch structure;

- porch angle;

Note. Professionals advise sloping the porch area and steps by 2-3° to avoid water accumulation. An alternative would be to install deck boards with a gap of 2-3 mm.

- foundation. Types, depth, characteristics of the soil underneath;

- number and size of porch steps. The standard recommends adhering to the following dimensions of steps: height - 170-180 mm, step depth (tread) - 300-350 mm. It is desirable that the number of steps be odd. These dimensions will make movement along the steps comfortable;

- presence and installation location of fencing (balusters and railings).

Note. In construction practice, there are no norms and rules regulating the parameters of the porch. The recommendations concern only the parameters of the steps.

Drawing of a wooden porch, as an illustrative example:

Scheme of a wooden porch

It’s convenient when working when the diagram of a wooden porch is made on a large sheet of paper and is always in front of your eyes.

A good alternative would be a life-size cardboard template. A paper template is indispensable when making a flight of stairs on a bowstring.

Foundation for the porch of a house

A correctly selected and poured foundation for a wooden porch is the key to its strength and durability.

A correctly selected and poured foundation for a wooden porch is the key to its strength and durability.

A wooden staircase to the porch can be installed without a foundation. But filling it will prevent the porch from moving due to seasonal soil movement.

When building a porch, you can choose one of the following types of foundation:

Columnar. Well suited for lightweight construction. The number of support pillars depends on the size of the porch.

Columnar. Well suited for lightweight construction. The number of support pillars depends on the size of the porch.

Slab. Structurally, it is a monolithic concrete slab. Designed for heavy (massive) structures. In most cases, a slab foundation does not need to be tied to the foundation of the main structure (house).

Slab. Structurally, it is a monolithic concrete slab. Designed for heavy (massive) structures. In most cases, a slab foundation does not need to be tied to the foundation of the main structure (house).

Tape. It has a significant margin of safety, while requiring less material costs. Connection to the foundation of the house is required.

Tape. It has a significant margin of safety, while requiring less material costs. Connection to the foundation of the house is required.

Material prepared for the website www.site

What kind of foundation is best to pour under the porch?

Some users recommend installing a strip foundation for the porch. In this case, the likelihood of a discrepancy between the porch and the house, as when using a columnar one, is eliminated. It also reduces material consumption compared to slab. The difficulty in arranging this type of foundation is that it needs to be tied to the house.

How to tie (connect) the foundation of the porch and the house?

First of all, adjacent foundations of the porch and house must have the same depth.

It is better not to immediately fill the place where the foundations are attached (fastened, connected), but leave a technical gap (a gap of 20-30 cm), in which there will be connecting elements (studs, reinforcement).

In the old foundation of the house, holes are drilled at a distance of 50-60 mm and studs with expansion anchors are driven in. From the new porch foundation, make a rebar outlet to these studs. Simply fitted (do not twist or weld).

After the new foundation has “settled” (stands) for a year (or at least a winter), preferably under load, the reinforcement can be connected (tied, twisted, welded). Fill the bond with concrete mortar.

The diagram below shows how to make a porch out of wood with the foundation tied to the house.

What is the depth of the foundation for the porch

The depth of the foundation for the porch must correspond to the depth of the foundation of the house and is located below.

A strip foundation is certainly an excellent solution for building a porch. However, not everyone needs a massive structure. After all, most porch staircases are built using stringers or bowstrings. In this case, it is not necessary to pour a strip foundation, but give preference to a pile or columnar foundation. When laying out such a foundation, you need to make concrete “pillows” for the supports and the base of the stringer/string.

The method for constructing a concrete pad is shown in the diagram.

How to build a wooden porch for a house

Let's consider the technology of constructing porches on pillars (piles, supports, beams) made of wood.

The construction of a porch on a foundation in the form of a support cushion for pillars (supporting pedestals) will be justified only if a number of rules are followed:

- the base of the stringer must rest against the waterproofing laid between the foundation and the wood of the stringer;

- for supports it is better to take coniferous wood, it is preferable in conditions of high humidity;

Advice. When choosing lumber for a support, it is better to give preference not to a 100x100 mm beam, but to two 50x100 boards fastened together.

- the wood of the supports should be treated with an antiseptic;

Note. The support should be processed to a height of 150-200 mm from the soil level. In this case, it is undesirable to use roofing felt. It prevents the flow of air, and the process of wood rotting begins from the inside. It is better to use drying oil or used machine oil.

- installation depth of supports is at least 800 mm;

- the wider and more massive the structure, the more supports there should be;

- After the concrete used to fill the supports has dried, you need to check their height. Adjust the height difference;

Note. When making a porch from wood, it is necessary to consider waterproofing and a drainage system. This will avoid distortion of the porch structure.

It is worth noting that there is no fundamental difference in how to build a porch for a wooden or brick house. It is important to make an informed choice of the type of foundation and, if necessary, correctly link it to the foundation of the house.

Flooring the porch landing and installing steps

Users' opinions differ on this issue. Some advise fitting the flooring boards as closely as possible to each other in order to prevent the appearance of cracks typical of dry wood, and also making a slope of 1.5-2° to allow water to flow smoothly from the flooring.

Others recommend leaving a gap of 2-3 mm so that water flows down unhindered. At the same time, they claim that these gaps do not entail the risk of injury when walking on the flooring (except for high-heeled shoes). Wooden steps for the porch - you can buy them ready-made or make them yourself. If the latter option is selected, a detailed description is provided below.

How to make steps for a porch out of wood

The steps are installed starting from the lower edge of the stringer/string. Fastening is carried out using self-tapping screws, which must be sunk into the wood to avoid injury.

The steps are installed starting from the lower edge of the stringer/string. Fastening is carried out using self-tapping screws, which must be sunk into the wood to avoid injury.

First, the riser is installed, then the step. This is due to the fact that it is easier to maintain the dimensions.

When constructing a staircase on a stringer, the steps are attached to it. Options for attaching the steps to the string are shown in the diagram.

Wooden porch fencing

It is important to note that if a flight of stairs has more than 3 steps, it is advisable to equip it with a fence. The fence for the porch can be metal (forged, stainless steel), wood, brick, stone (or concrete). Wooden railings for the porch can become not only a guarantee of safety of movement, but also an additional decoration.

Recommendation. Provide safety elements - anti-slip coating on the porch steps (non-slip, anti-slip, rubber, rubber coating, tiles, mat). After all, frozen moisture (icing) makes movement on them dangerous.

We have sorted out the question of how to make a wooden porch; now it is important to study how to extend its service life.

How to protect a wooden porch - care

A canopy over the porch will protect the wooden steps and the structure as a whole from external factors (sun, snow and rain). A wooden canopy over the porch of a wooden house will look especially good. For buildings made of other materials (for example, for a stone house), polycarbonate, corrugated sheets, tiles or other roofing materials are suitable. The visor can be made with or without stands. The main thing is that the visor supports do not interfere with movement.

Wood processing is divided into pre-operational and operational. The first involves applying special compounds before the construction of the porch begins. The composition of the solutions will reduce the tendency of wood to rot, deform, dry out, etc. And the second will make it possible to preserve the original appearance of the structure. Such processing may include painting, waxing or varnishing.

Painting a wooden porch

- pine wood needs to be exposed (coated) with paint in several layers and the layer periodically renewed;

- Before applying paint, you need to open (treat, impregnate) the wood with a primer;

Advice. The primer will preserve the properties of wood, but the surface will need to be painted every 3-6 years. Without impregnation, the paint will last up to 10 years, but the properties of the wood will deteriorate significantly.

- It is not recommended to coat pine with transparent compounds. Sand and dirt are pressed into the soft rock;

- larch or deciduous wood can be opened with transparent compounds. The impregnation oil Vermeister Deck.Oil has proven itself to be excellent;

- When choosing what to paint a wooden porch on the street, you need to know that the compositions for coating the wood outside and inside the house may differ. To paint a wooden porch from the street (outside), use the following paints and enamels:

- oil-based (due to their pungent odor they are gradually losing popularity);

- water-based (need constant updating);

- alkyd (resistant to moisture and mechanical abrasion);

- polyurethane (used mainly in industrial environments);

- reactive (consist of two components; their distribution is limited by high cost and short time for application after mixing the components).

- Each renewal of the coating on wood is carried out only after stripping the surface of the previous layer of old paint.

How to attach a wooden porch - video

Following the steps listed above will allow you to create a beautiful, reliable and functional wooden porch with your own hands.

A wooden porch is the most common solution for a country house. It is inexpensive, can be built quickly, and even a novice craftsman can work with wood. Although the design seems quite simple, you need to know how to make wooden steps for a porch.

There are many technical subtleties that need to be taken into account during design and construction work.

What does a step consist of and how is it calculated?

Any wooden house needs a porch: due to the high plinth, the door is located quite high from the ground, and it will be inconvenient to enter the house. You will need a porch with at least two steps, and the exact number and size of them depend on the specific features of the house.

- DIY steps for a porch made of wood consist of a tread (horizontal part) and a riser (vertical part). They are built based on the following parameters:

- The height of the step is the size of the riser. Normally, it will be from 16 to 21 cm: a steeper staircase will be inconvenient to climb.

- Depth of steps. This is the width of the tread that should be comfortable to step on. The depth of the step should be at least 27 cm, the optimal size is 32 cm.

- The angle of the porch. An angle starting from 27 degrees is considered normal. The staircase to the house will be gentle, and even a small child or an elderly person can easily climb it. Flights of stairs with a slope of more than 45 degrees can only be attached; such structures are usually used for attics and attics.

Width of the flight of stairs. For one person you need at least 90 cm of width, and on such a staircase it will be difficult for two people to separate.

The porch area should be located a few centimeters below the front door, especially if the house has just been built. During shrinkage, the overall height of the house may decrease, then the door will touch the surface of the porch when opened.

What material is best to make steps from?

When choosing how to make steps for a wooden porch, you should pay attention to coniferous wood. Everyone is familiar with pine and spruce, and they are relatively inexpensive. However, cedar or larch will be more expensive and more reliable - these types of wood do not rot or swell even in high humidity, so the constructed porch will not have to be repaired for a long time.

If you purchased lumber with natural moisture, it must be thoroughly dried. The boards are dried in stacks in a dry room with good ventilation; this may take quite a long time. The wood dries within 3-4 months, during which time the room should not be cold.

Sometimes it is more profitable not to wait, but to immediately purchase dried lumber that has already been processed in special chambers. You can check the condition of the wood by looking at the shavings: if the wood is dry, the shavings will break and not bend. To protect against rot and fungus, the boards should be treated with an antiseptic - it is applied with a brush or roller; you can also dip the boards in the solution.

Before construction, you need to prepare the following tools: an electric planer for cutting boards, a grinder and a circular saw. In addition, you will need a pencil and a ruler to make a template.

The thickness of the boards for the steps is 3-4 cm. The template is applied to the tree and traced, after which steps of the same size are cut out of the board using an electric planer.

It is advisable to process the cut steps. Parquet varnish is most suitable for this: it will reliably protect the wood. It is applied in several layers, and each new layer should be started only after the previous one has dried.

How to make a wooden staircase

The platform for installing the stairs can be not only 4-angled, although this is the most common solution. You can make a porch of a round, hexagonal or other shape, in addition, it can be corner. All the features of each model are reflected in the drawings; the master must clearly understand how the structure will be constructed.

How to build steps to a wooden porch? Work on the construction of the porch begins with concreting the supports. The platform can be supported by 2 or 4 pillars, depending on the size; in some cases, it is supported by a horizontal beam attached to the wall.

For a light porch, you can choose wooden supports from boards: they are placed at one end in the pits, and the base is filled with concrete. The supports must also be soaked in advance with any antiseptic.

In addition, concrete “nickels” should be located in those places where bowstrings or stringers will rest on the ground. This will allow the ladder to support the weight of one or more people. When the base is ready, you can begin assembling the system:

Assembly takes little time, and very soon the ladder will rise to the support platform. You can check the reliability of the steps, after which you need to move on to arranging the parapet and canopy.

Construction of railings and canopy for a wooden porch

It will not be difficult to make wooden steps for the porch with your own hands, but the work on building the stairs does not end there. To make it convenient to use, you need to install railings with handrails, and also take care of installing the canopy.

Railings are fences for the porch, the height of which is about 90 cm. They will require support posts made of timber, balusters (turned posts) and the railings themselves.

Support posts and balusters are attached to the steps using metal pins, after which you need to install the balusters and cover the finished railings with comfortable handrails. Although installing railings is not necessary for your home porch, it is better to take care of your safety.

Railing elements can be ordered ready-made from a turning workshop. Making beautiful balusters yourself is problematic, so it’s easier to purchase them to order in any workshop. The railings and the entire staircase structure can be painted in any color; not a single wooden element should be left unprotected.

Installing a canopy over a wooden porch

It will also be easy to install the visor. It can be very small, just to cover the steps, or you can build a spacious, collapsible canopy that you can take with you when going outdoors. The visor can be made in the following ways:

The canopy must be in harmony in color and shape with the roof of the house so that the architectural composition is unified. It can be single-pitch, gable, hipped, arched, etc., it all depends only on the skill of the owner of the house.

The stringer differs from the bowstring in that it is located not on the sides of the steps, but under them, so it is invisible from the side. It is installed in the same way on the platform and on concrete heels, after which steps and risers are attached to it.

The steps are installed on top of the stringer; for this purpose it is given a special shape, reminiscent of a saw. To attach steps and risers, you can use self-tapping screws, which are closed on top with cork plugs.

If there are two stringers, they must be strictly identical, otherwise the steps will be skewed. To achieve the desired shape, a template is first made taking into account the depth and height of the steps. After this, the template is applied to the boards, and the necessary elements are cut out of them with a jigsaw.

Stairs with stringers are in demand because they look lighter and less cumbersome. They can be built quickly, and they last no less long than bowstring structures.

For a large porch, you can use a metal stringer rather than a wooden one, and the steps for it can be made of wood. From the outside, the ladder will look the same, but it will be much more durable, although heavier.

Metal and concrete stairs with wooden steps

Wood is a warm and pleasant to the touch material, so it is also used if the base of the staircase is made of other materials. If a metal structure is chosen for the house, boards can be laid on the frame of the steps as treads.

They can be painted in any color, and the staircase will look harmonious. A wooden porch will look especially beautiful if you combine metal railings with forged elements with varnished wooden handrails.

Wooden steps for stairs are currently the most popular. Even if the staircase is metal or concrete, the steps are most often made of solid wood. This is because the tree:

- unlike concrete and metal, it is easy to do it yourself;

- conducts heat poorly, so the surface will be warm to the touch, which is important when planning an internal staircase;

- looks aesthetically pleasing;

- durable and reliable. With proper manufacturing and care, it can last for several decades.

Calculation of staircase steps - winders and turns

Calculation of staircase steps is carried out according to standard dimensions:

Step height— length of the vertical part (riser). For internal stairs it should be between 15 and 22 cm.

Step depth — This is the distance from the edge of the tread to the riser. It should provide reliable support for the leg with a full foot, which means it should be no less than 250 and no more than 400 mm.

In some cases, the depth of the tread may vary. For example, on a spiral staircase it is wider at the outer edge of the flight and decreases towards its inner side. Also with turning steps, which have a constant tread depth only in the center and “walking” along the edges, which greatly complicates the calculation of winder steps.

The use of protruding steps allows you to increase the depth of the tread while maintaining the same length of the staircase. Another trick is to remove the risers, this will also provide additional legroom.

Step sizes may vary slightly, but must comply with the basic calculation formula: the sum of twice the size of the riser and tread should be in the range from 60 to 65 cm.

2a + b = 60..65 cm

Step width, that is, the distance between its edges. Varies depending on many factors. For internal stairs, the standard tread width is 90-100 cm. If it is expected that there will be heavy traffic, the width of the flight of stairs increases to one and a half meters.

Tread thickness. Depends on the width of the step and has a ratio of 1:20. That is, with a width of 90 cm, the thickness should be at least 4.5 cm. It is not recommended to take a value less than 3.5 cm. Sometimes, the thickness of the tread increases to 6 cm.

In the case when the step is superimposed on an existing wooden, concrete or metal base, its thickness can be reduced by approximately a centimeter.

Riser thickness usually ranges from 18 to 25 mm.

The optimal angle of inclination of the stairs - how to calculate

The most convenient angle of inclination of the stairs is in the range from 23 to 37°. The steeper the structure, the less space it needs, and accordingly, the flatter the slope, the more space will be needed for its installation.

If the angle is more than 45°, then the staircase will be classified as folding or attached; if it is less than 23°, it can be replaced with a ramp (a flat inclined platform). When the slope of the march is 40°, the descent becomes uncomfortable, and at 45° or more, you can only descend backwards.

Dependence of the size of the steps on the steepness of the stairs

Dependence of the size of the steps on the steepness of the stairs

Calculate the number of steps in a march

Floor height is the distance from the finished floor of the lower floor to the floor of the upper floor, i.e. The size includes the thickness of the coating (tiles, laminate, etc.).

If the staircase design and floor height are known, the number of steps can be set graphically, and then the width of the tread can be determined using safety formulas.

First you need to plot the flight of stairs on graph paper using a convenient scale.

Graphic calculation of stairs with size correspondence table

Graphic calculation of stairs with size correspondence table

The calculation error that occurs when rounding heights should be distributed to the lower frieze step, and all the others should be made the same size.

How to make steps with your own hands from wood

Having completed all the described calculations and measurements with our own hands, we will try to make wooden steps. First of all, you need to choose the right material.

Solid woods are mainly used: maple, beech, oak. When purchasing boards, you need to pay attention to the evenness of the surface. If you have no planing experience, it is advisable that the board has already been planed.

If you want to start making steps “from scratch” and buy raw boards, you must first dry them thoroughly. To do this, wooden boards are stacked in a dry, well-ventilated and not too cold place. To prevent mold from appearing, it is treated with an antiseptic. A board 3–4 cm thick needs four months to dry to the desired condition. In well-prepared wood, the chips break rather than bend. If the material is not completely dried, the steps may become deformed over time.

Tools you will need:- electric planer, if you plan to plan the board;

- circular saw for cutting;

- Sander;

- router for edge processing.

Having made the templates according to the selected dimensions, we begin to cut out the treads and risers from the prepared boards. Difficulties may arise with turning steps, as they have a non-standard shape. Let's look at what winder steps might look like (in the photo the sizes are arbitrary).

Upon completion of the work, protective coatings for wood should be applied to the surface of the resulting parts in at least three layers. It is recommended to use wear-resistant parquet varnish. Now let's start the installation.

Installation of wooden steps - installation on stairs

Fastening wooden steps is carried out in three ways:

- to the stringer;

- to the bowstring;

- pain. This method is considered the most difficult and requires special skills. For those who decide to work with their own hands, the first two options are more suitable.

Let's say you decide to attach the steps to the stringers. In this case, there are several options for connecting the tread and riser:

- using screws in the countersunk area;

- groove connection. A groove of sufficient depth is cut in the tread at the place where the riser should be;

- with the installation of an additional triangle-shaped rail, which plays the role of a support. If the step is made of hardwood, then you can use softwood dowels. The riser and tread connected to each other are installed on top of the teeth and secured.

All three methods assume that the parts to be joined will be additionally glued;

- using steel mounting angles;

If steps for wooden stairs are attached to a bowstring, there are three ways to fix them:

A). using a block;

b). metal corner;

V). in the groove The groove must be deep enough. Additionally, the connection is sealed with glue.

Metal staircase with wooden steps

A metal staircase with wooden steps combines the strength of metal and the sophistication of wood. If you install the steps without the help of professionals, with your own hands, you can save a lot of money.

Fastening the steps of the stairs to the metal frame is carried out using holes made every 15 cm with an indentation of approximately 2 cm from the edge.

No matter how well the welding of metal parts is performed, small differences in height are possible. To level the surface yourself, a backing is glued to the frame using a special adhesive with a filling effect. As a backing, you can use 1 cm thick plywood, which is additionally fixed with self-tapping screws. It is not recommended to use polyurethane foam to secure plywood, since it is not designed for such loads and, after drying, will begin to crumble, which will lead to loosening of the steps.

A wooden tread is secured to the plywood using clamps and secured with self-tapping screws from below or from above, in a hidden position.

A clamp is an auxiliary tool used to secure objects while working with them, or to tightly press surfaces together, for example, when gluing.

It is recommended to make the steps slightly protruding beyond the metal base - such a staircase looks more attractive, hiding the ugly frame of the structure. To prevent chipping at the ends, hard wood is used. The corners are chamfered, giving them a rounded shape. The finished steps are coated with wear-resistant parquet varnish.

Wooden steps on a concrete staircase

Concrete stairs are reliable and durable, but do not have a beautiful appearance. Wood cladding is an excellent option for decorating a structure. Properly executed cladding will delight you with its appearance for a very long time. The only drawback is its high cost. costs approximately twice as much as the same product made entirely from solid wood.

If you have decided in advance to use wood as a covering for the steps, this must be taken into account when calculating - do not forget to include the dimensions of the wooden boards in the overall dimensions. Carefully prepared formwork will make your work easier. After all, a difference in the height of steps of more than one centimeter is very difficult to eliminate in the finished structure.

Before you begin installing the steps, you must allow the structure to dry thoroughly. Working with wet concrete is fraught with deformation of the cladding due to high humidity. And the concrete itself will begin to crumble over time. To prevent this from happening, the staircase, after manufacturing, must stand for at least 3 months. It’s even better if it lasts for one heating period. When the structure is completely dry, you can begin work on its cladding.

No matter how carefully the formwork for the stairs is made, there will definitely be unevenness, distortions, and non-uniform step heights. All this must be leveled using a screed, if the unevenness is significant, or using a self-leveling mixture.

If the riser height difference is more than 1 cm, it is recommended to make plywood formwork around the perimeter.

When the self-leveling mixture or screed is completely dry, the surface must be thoroughly cleaned and primed. Only after this can further work be carried out.

Now the plywood sheets are glued on. This is necessary in order to finally level the surface of the concrete and create a moisture-proofing layer. The plywood is glued with a special mastic and additionally fixed with dowels, as shown in the photo.

Installation of steps begins from the bottom, from the very first riser. In order to secure it to the floor, bolts are screwed into the end so that they protrude by 6 - 8 cm, the caps are cut off, and a place is marked on the floor where they will stand. Holes are drilled in these places, filled with epoxy resin, after which the riser is fixed in them. When it is secured, a tread is laid on top of plywood pre-coated with glue, to which the next riser is already attached using self-tapping screws and glue.

Place a weight on the newly installed step and wait until the glue hardens. This is how the stairs are lined with wood.

Wooden steps for the porch - entrance staircase to the house

Porch stairs are still popular today, especially for cobblestone and log houses. Boards are made mainly from abrasion-resistant hardwoods, such as maple, oak, ash, and beech.

Since the staircase is located outdoors, it is very important to protect it from environmental influences, in particular from moisture. All parts that will come into contact with the ground are impregnated with mineral oils. Open surfaces, including steps for the porch, are covered with hot drying oil, and then treated with varnish or painted with enamels and paint. Alkyd enamels intended for outdoor use are well suited.

Protecting the steps will extend the life of the stairs, but the surface must be checked periodically, since wood will still deteriorate over time. A step damaged by rot, which looks intact on the outside, can cause injury.

The decoration of the porch stairs has its own characteristics. In order to secure the cladding to the concrete base, even at the stage of manufacturing the porch, metal bookmarks are installed in the concrete, to which the steps will subsequently be attached. Next, the wood is processed using protective and decorative wood coatings.

It is important not only to build a large and beautiful house, but also to provide a comfortable, functional and attractive approach to it. Since most private houses are built on a basement, there is a need to add a porch with steps. This is an important stage in construction, since the staircase must be comfortable for movement, safe, and not spoil the appearance of the house.

In this article we will look at the basic standards and technology for constructing a staircase with steps for a porch with our own hands, consider the main materials used for construction, as well as the variety of shapes and designs of these structures.

Installation of stairs for the veranda

The porch is a platform with steps located directly in front of the entrance to the house. The design can be of any shape and size (narrow, or spacious, wide, which is already a full-fledged terrace). For convenient ascent by steps and to ensure the safety of the residents of the house, the platform and stairs can be framed with railings.

Beautiful steps to the porch, photo

Calculation of the size of the structure

To ensure that entry and exit from the house is comfortable for all its visitors, before its construction you should learn how to calculate the dimensions of the structure. There are certain building standards for this.

When constructing a staircase, the following points are taken into account:

- the height of the porch steps is the riser;

- step width - tread depth;

- march inclination angle.

To make it comfortable for a person with any shoe size to climb the stairs, the width of the step should be in the range of 25-30 cm. A comfortable height for climbing is in the range of 12-20 cm.

The angle of the march is also very important. The stairs should not be too steep - this makes it difficult to climb and increases the risk of injury. The permissible tilt angle is 25-45 degrees.

Schematic calculation of steps for a porch

Materials for production

Various materials can be used to construct a staircase; standard and original design options can also be used. Many companies offer ready-made solutions for porches for country houses, but it is quite possible to build steps for a porch with your own hands.

Basic materials for the construction of external porch steps:

- concrete;

If you want to emphasize the environmental friendliness of a house made of natural wood, timber, and preserve its special energy, you can build a wooden staircase to the veranda. The main advantage of wooden porch steps is their presentable appearance, the comfort and warmth that they give to the house. They are also convenient because you can choose material of different price categories (prestigious oak or beech, or inexpensive pine needles).

Advice: For the construction of a wooden structure, it is preferable to use coniferous wood and larch.However, a wooden porch is vulnerable to precipitation and temperature changes. Therefore, it should be treated with a special protective impregnation and additionally varnished on top.

Beautiful wooden steps for the porch, photo

Metal structures are more durable. They are not deformable, can withstand heavy loads, and can be installed even without laying a foundation. The disadvantage of a metal ladder is its susceptibility to rust. Therefore, metal products should be treated with a special anti-corrosion compound, and also periodically tinted. Metal entrance steps can be of any configuration; they cost more than wooden ones.

Metal ladder with forging elements

Please note: if you decide to make porch steps from metal, this will require skills in working with a welding machine.A brick staircase is also reliable and stable. Brick is a durable material that withstands environmental influences well. The cost of this material is slightly higher than wood, and it will take more time to build a porch from it.

Advice: To build steps, it is better to take clinker bricks; they look more presentable.

Unusual, but a completely brick porch looks very beautiful

If you like a durable monolithic coating, build concrete steps for the porch. They are made by pouring mortar into a specially constructed formwork. In terms of cost and volume of work performed, steps for a porch made of concrete are comparable to wooden ones, but in terms of strength they significantly exceed them.

Concrete structure covered with tiles

A new material that can be used as a replacement for wood for the construction of external stairs is wood-polymer composite (WPC). Products made from it do not crack (unlike ceramic ones), do not absorb moisture, do not slip, and do not require additional processing or painting.

Luxurious platform and steps for the porch made of DCP

Staircase decoration

The choice of the type of porch and materials for its construction and decoration should be approached very carefully, because the comfort and convenience of all residents of the house depends on this. In addition, the design must be in harmony with the house.

How to cover porch steps? The naturalness and natural color of a wooden staircase will emphasize the design of a house in a traditional style, while a metal structure is suitable for building a more modern design.

On a note: A combination of light and dark shades, forged inserts in combination with red clinker bricks always looks advantageous.For the cladding of external structures, materials that are resistant to atmospheric influences are most suitable - tiles, stone, porcelain stoneware.

Using ceramic tiles for porch steps, photo

A staircase made of porcelain stoneware will be reliable, durable and safe. The material is very durable, does not slip, does not require additional protection, and withstands bad weather and frost well.

If you want to make a beautiful and practical staircase to the veranda, pay attention to natural stone. Granite steps for a porch can have a different pattern and shade. For external work, plates with special heat treatment are used that do not slip.

Beautiful porch, combination of granite and forging

A brick structure can be decorated with inserts of stone and multi-colored glass. The free space will be filled with hanging flower pots and decorative forged elements.

The style and design of the porch reflects the taste and preferences of the owners of the house

Possible shapes of entrance stages

As for the shape of the staircase, it can be of different types. The span can have a rectangular, trapezoidal, or semicircular shape. More creative solutions are also possible.

DIY semicircular porch steps, paved with paving slabs

The entrance to the house can be equipped not only on one side - staircases for the veranda with two multi-directional flights can be used. And if you add railings to the structure, this will make the platform and stairs safer for children and the elderly.

Step-by-step technology for building concrete stairs

How to make steps on a concrete porch? A flight of stairs can have a stacked or monolithic base. To install a monolith, you should know how to pour the solution into the formwork. It is constructed from beams and boards.

Important: To prevent the structure from deforming under the pressure of concrete, it is strengthened on all sides with spacers.

Construction of formwork for porch steps

At the next stage, the structure is concreted - poured with concrete. After it has completely dried, the formwork is removed and the finishing of the finished staircase begins.

Finishing work - laying tiles on the steps of the porch

Advice: Before covering a concrete surface with tiles or stones, it should be cleaned from the saw and treated with a primer for better adhesion.Step-by-step technology for building a staircase for a wooden porch

Making wooden steps requires certain woodworking skills. Before building the structure, you should draw up a project by determining the dimensions of the porch steps.

For work, you should prepare boards 50-60 mm thick, nails and screws for fastening them, as well as tools (level, tape measure, hammer, screwdriver, saw), as well as special antiseptic and protective agents for wood processing.

First, bowstrings (stringers) are cut out of a wooden board. Then they are attached to the porch and the details of the steps are mounted on them. Nails and screws are used for fastening. At the end, railings and a canopy are installed.

Finished wooden steps are treated with an antiseptic and then varnished

Additional options

In addition to using various types of finishing, you can install floor heating on the porch. The heating system is installed under the flooring before tiling the surface.

Bottom line

Street steps are an important element of the house, because they make the entrance to the home more comfortable and beautiful. By calculating them correctly, choosing the shape and materials for construction and finishing, you will end up with a comfortable and functional entrance to the mansion.