A sensor is called active if it converts. What is a sensor? Oil pressure sensor - functions, failure

Read also

Elements of automatic control systems

Automation- a branch of science and technology about the management of various processes and control of their progress, carried out without direct human participation.

Managing various processes without human intervention is called automatic control, and the technical means by which it is carried out - by means of automation.

Parameters of the production process that must be constantly maintained or changed according to a certain law are called controlled quantity.

A set of technical means designed to automate production processes is automatic system.

Depending on the functions performed, automatic systems are distinguished control, management and regulation.

Systems consist of a control object and an automatic control device. If the input influences for the control device are only external influences, the system is called open(without feedback), if external and internal - closed(with feedback).

Depending on the method of generating control signals, systems are divided into continuous And discrete(digital).

Automation systems consist of a number of interconnected elements that perform certain functions and provide a comprehensive control process.

In accordance with the functions performed, all elements of the automatic system are divided into three groups:

1) measuring

2) transformative

3) executive

Measuring The group consists of various types of sensors.

Transformative— amplification devices, regulators, digital and microprocessor devices.

Executive— electric motors, contactors, control valves, etc.

Automation elements are called structurally complete devices that perform certain independent functions of signal conversion in automation systems.

Each element converts the energy received from the previous element and transfers it to the next one. Elements can be electrical or non-electric: hydraulic, pneumatic, mechanical, etc.

The most important requirement for automation devices is high reliability. Unreliable operation of the automatic control system (failure or error) can lead to disruption of the production process and other serious consequences.

Of particular importance is the use of automatic systems in those areas where human capabilities are not able to provide the proper level of control over the technological process. This may apply to both rapidly occurring processes (for example, voltage changes) and harmful factors (for example, nuclear reactions, chemical production).

Automation of various technological processes, control of various machines and mechanisms require numerous measurements of various physical quantities. Information about the parameters of the controlled system or device is obtained using sensors or otherwise sensors.

Sensor is a device that converts the input effect of any physical quantity into a signal convenient for further use (most often into an electrical signal).

That. sensors convert your favorite value into an electrical signal, which is convenient to transmit, process, display, etc.

The sensors used are very diverse and can be classified according to various criteria:

1) Depending on the type of input (measured) quantity, there are: mechanical displacement sensors (linear and angular), pneumatic, electrical, flow meters, speed, acceleration, force, temperature, pressure sensors, etc.

Currently, there is approximately the following distribution of the share of measurements of various physical quantities in industry: temperature - 50%, flow (mass and volume) - 15%, pressure - 10%, level - 5%, quantity (mass, volume) - 5%, time - 4%, electrical and magnetic quantities - less than 4%.

2) Based on the type of output value into which the input value is converted, non-electrical and electrical sensors are distinguished. Most sensors are electrical.

3) Based on the principle of operation, sensors can be divided into two classes: generator and parametric (modulator sensors). Generator sensors directly convert the input value into an electrical signal. Parametric sensors convert the input value into a change in any electrical parameter (R, L or C) of the sensor, therefore they require a power source for operation.

Based on the principle of operation, sensors can also be divided into ohmic, thermometric, photoelectric, inductive, capacitive, etc.

There are three classes of sensors:

Analog sensors that produce an analog signal proportional to the change in the input value;

Digital sensors that generate a sequence of pulses or a digital code;

Binary (binary) sensors that produce a signal of only two levels: “on/off” (in other words, 0 or 1).

Ohmic (resistive) sensors—the operating principle is based on a change in their active resistance when the length changes l, cross-sectional area S or resistivity p, i.e.

R=pl/S (1.1)

In addition, the dependence of the active resistance value on temperature, contact pressure and illumination is used. In accordance with this, ohmic sensors are divided into: contact, potentiometric (rheostat), strain gauge, thermistor, photoresistor.

Contact sensors are the simplest type of resistor sensors that convert the movement of a primary element into an abrupt change in the resistance of an electrical circuit. Contact sensors are used to measure and control forces, movements, position, temperature, dimensions of objects, etc. Contact sensors include travel and limit switches, contact thermometers and so-called electrode sensors, which are mainly used to measure limit levels of electrically conductive liquids.

The disadvantage of contact sensors is the limited service life of the contact system, but due to the simplicity of these sensors they are widely used.

Rheostatic The sensors are a resistor with varying active resistance. The input value of the sensor is the movement of the contact, and the output value is the change in its resistance. The moving contact is mechanically connected to the object whose movement (angular or linear) needs to be converted.

The most widely used is a potentiometric circuit for connecting a rheostat sensor, in which the rheostat is connected according to a voltage divider circuit (Fig. 1.1). A variable resistor connected according to a voltage divider circuit is called a potentiometer.

The output value U out of such a sensor is the voltage drop between the moving and one of the fixed contacts. The dependence of the output voltage on the movement “x” of the contact U out = f(x) corresponds to the law of resistance change along the potentiometer.

Figure 1.1 — Potentiometric circuit for switching on a rheostat sensor

Typically, rheostatic sensors are used in mechanical measuring instruments to convert their readings into electrical quantities (current or voltage), for example, in float liquid level meters, various pressure gauges, etc.

Strain gauges are used to measure mechanical stress, small deformations, and vibration. The action of strain gauges is based on the strain effect, which consists in changing the active resistance of conductor and semiconductor materials under the influence of forces applied to them.

Thermometric sensors (thermistors) - resistance depends on temperature.

Thermal resistors are used as sensors in two ways:

1) The temperature of the thermistor is determined by the environment; The current passing through the thermistor is so small that it does not cause the thermistor to heat up. Under this condition, the thermistor is used as a temperature sensor.

2) The temperature of the thermistor is determined by the degree of heating by a constant current and cooling conditions. In this case, the established temperature is determined by the conditions of heat transfer from the surface of the thermistor (the speed of movement of the environment - gas or liquid - relative to the thermistor, its density, viscosity and temperature), so the thermistor can be used as a sensor of flow speed, thermal conductivity of the environment, density of gases, etc. P.

Figure 1.2 - Using a self-heating resistor as a flow sensor

For example, to measure the volume of air consumed in automobile engines, a self-heating resistor is installed in the air duct. The resistance of such a resistor changes due to cooling by the air flow, as a result of which the resistor acts as a flow sensor (Fig. 1.2).

Inductive sensors are used to obtain contactless information about the movements of the working parts of machines and mechanisms.

The principle of operation of the sensor is based on a change in the electromagnetic field when metal objects enter the sensor’s coverage area (the sensor does not respond to non-metallic materials). Inductive sensors are mainly used as proximity switches (does not require mechanical action) for position determination (limit and limit switches).

Figure 1.3 shows examples of the use of inductive sensors as position, angle, and speed sensors.

Figure 1.3 - Examples of using an inductive sensor (VBI - non-contact induction switch)

The disadvantages of inductive sensors are their short response distance and relatively low sensitivity.

Capacitive sensors - the principle of operation is based on the dependence of the electrical capacitance of the capacitor on the size, relative position of its plates and on the dielectric constant of the medium between them.

For a double-plate flat capacitor, the electric capacitance is determined by the expression:

C = e 0 eS/h (1.2)

where e 0 is the dielectric constant;

e is the relative dielectric constant of the medium between the plates;

S is the active area of the plates;

h is the distance between the capacitor plates.

The dependence of capacitance on the area of the plates and the distance between them is used to measure angular displacements, very small linear displacements, vibrations, movement speed, etc.

Widely capacitive sensors are used to monitor the level of liquids and bulk materials. In this case, it is possible to place the sensors outside the tank or hopper. Material entering the working area of the sensor causes a change in the dielectric constant e, which changes the capacitance and triggers the sensor (Fig. 1.4).

| A) | b) |

Figure 1.4 - Capacitive sensor

a) distribution of the electric field of the capacitor,

b) example of minimum and maximum level control

In addition, sensors for the thickness of a layer of non-conducting materials (thickness gauges) and control humidity and composition of the substance work to measure the value of dielectric constant e.

The advantages of capacitive sensors are simplicity, high sensitivity and low inertia. Disadvantages - the influence of external electric fields, the relative complexity of measuring devices.

Induction sensors convert the measured value into induced emf. These sensors include tachogenerators, whose output voltage is proportional to the angular speed of rotation of the generator shaft. Used as angular velocity sensors.

The tachogenerator (Fig. 1.5) is an electrical machine operating in generator mode. The controlled object is mechanically connected to the tachogenerator rotor and causes it to rotate. In this case, the generated EMF is proportional to the rotation speed and the magnitude of the magnetic flux. In addition, with a change in rotation speed, the frequency of the EMF changes.

Figure 1.5 — Tachogenerator

a) design, b) diagrams of input and output EMF

Temperature sensors are the most common; a wide range of measured temperatures, a variety of conditions for using measuring instruments and requirements for them determine the variety of temperature measuring instruments used.

The main classes of temperature sensors for industrial applications: silicon temperature sensors, bimetallic sensors, liquid and gas thermometers, temperature indicators, thermocouples, resistance thermal converters, infrared sensors.

Silicon temperature sensors use the temperature dependence of semiconductor silicon resistance. The range of measured temperatures is -50…+150 0 C. They are mainly used to measure the temperature inside electronic devices.

A bimetallic sensor is a plate made of two dissimilar metals that have different temperature coefficients of linear expansion. When heated or cooled, the plate bends, opening (closing) electrical contacts or moving the indicator needle. The operating range of bimetallic sensors is -40 to +550 0 C. They are used to measure the surface of solids and the temperature of liquids. The main areas of application are heating and water heating systems.

Thermal indicators are special substances that change their color under the influence of temperature. Produced in the form of films.

Resistance thermal converters (thermoresistors) are based on changes in the electrical resistance of conductors and semiconductors depending on temperature.

As the temperature rises, the resistance of metals increases. For the manufacture of metal thermistors, copper, nickel, and platinum are used. Platinum thermistors allow you to measure temperatures in the range from -260 to 1100 0 C.

Semiconductor thermistors have a negative or positive temperature coefficient of resistance. In addition, semiconductor thermistors, with very small sizes, have high resistance values (up to 1 MOhm).

They are used to change temperatures in the range from -100 to 200 0 C.

A thermocouple is a connection (junction) of two dissimilar metals. The work is based on the thermoelectric effect - in the presence of a temperature difference between the junction T 1 and the ends of the thermocouple T 0, an electromotive force occurs, called thermo-electromotive (abbreviated thermo-EMF). In a certain temperature range, we can assume that thermo-EMF is directly proportional to the temperature difference ΔT = T 1 - T 0.

Thermocouples make it possible to measure temperatures in the range from -200 to 2200 0 C. The most widely used materials for the manufacture of thermoelectric converters are platinum, platinum-rhodium, chromel, and alumel.

Thermocouples are cheap, easy to manufacture and reliable in operation. Measuring multimeters are equipped with thermocouples.

Infrared sensors (pyrometers) - use radiation energy from heated bodies, which allows you to measure surface temperature at a distance. Pyrometers are divided into radiation, brightness and color. They allow you to measure temperature in hard-to-reach places and the temperature of moving objects, high temperatures where other sensors no longer work.

Piezoelectric The sensors are based on the piezoelectric effect (piezoelectric effect), which consists in the fact that when some crystals are compressed or stretched, an electric charge appears on their faces, the magnitude of which is proportional to the acting force.

Used to measure forces, pressure, vibration, etc.

Optical (photoelectric) The sensors operate either on the basis of the internal photoelectric effect - a change in resistance when the illumination changes, or they produce a photovoltage proportional to the illumination.

Distinguish analog And discrete optical sensors. With analog sensors, the output signal varies in proportion to the ambient light. The main area of application is automated lighting control systems.

Discrete type sensors change the output state to the opposite one when a set illumination value is reached.

Photoelectric sensors can be used in almost all industries. Discrete sensors are used as a kind of proximity switches for counting, detection, positioning and other tasks.

Figure 1.6 - Examples of using photoelectric sensors

Registers a change in the light flux in the controlled area associated with a change in the position in space of any moving parts of mechanisms and machines, the absence or presence of objects.

Optical proximity sensor consists of two functional units: receiver and emitter. These units can be made either in one housing or in different housings.

There are two methods for detecting an object using photoelectric sensors:

1) Beam crossing - in this method, the transmitter and receiver are separated into different housings, which allows them to be installed opposite each other at a working distance. The operating principle is based on the fact that the transmitter constantly sends out a light beam, which is received by the receiver. If the light signal from the sensor stops due to obstruction by a foreign object, the receiver immediately reacts by changing the output state.

2) Reflection from an object - in this method, the receiver and transmitter are located in the same housing. During the operating state of the sensor, all objects falling into its working area become a kind of reflectors (reflectors). As soon as a light beam reflected from an object hits the sensor receiver, it immediately reacts by changing the output state.

Homework

1) Name what types of sensors and explain why they can be used as position sensors.

2) Name what types of sensors and explain why they can be used as speed sensors.

3) Name what types of sensors and explain why they can be used as sensors - flow meters.

4) The figure shows an inductive sensor.

Write down which sensor parameters and in which direction will change when the anchor moves:

1) up; 2) down; 3) to the right; 4) left.

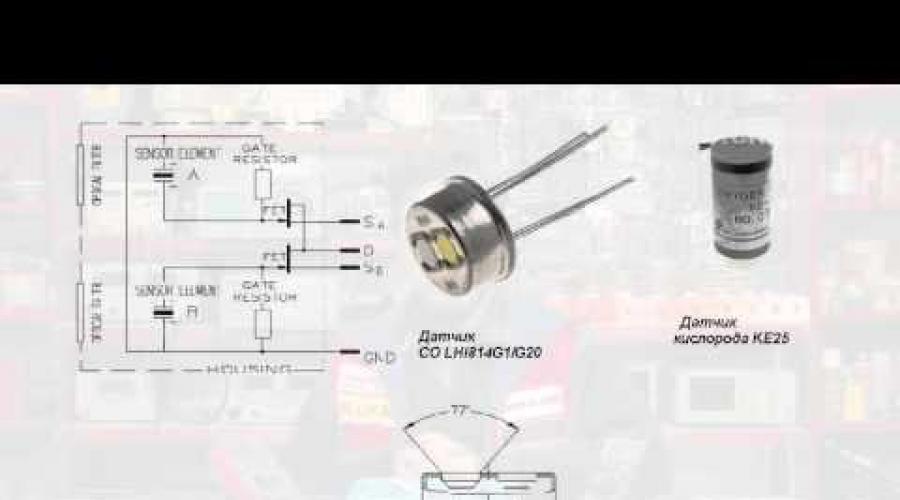

5) Explain the purpose of the sensor shown in the figure (left).

6) Explain the purpose of the sensors shown in the figure (right). Why are two sensors used?

What is a sensor?

Surely you have heard the word “sensor” more than once. Obviously, this word means some kind of technical device. What is a sensor and how does it work? What types of sensors are there? Let's consider all these questions in more detail.

Sensor concept

Currently, a sensor is usually called an element that converts information received from the environment into an electrical signal for the purpose of further transmitting information to some other device. Typically, the sensor is a structurally separate part of the measuring system.

Sensors are used everywhere: in cars, heating systems, water supply, in production, in medicine, even in catering establishments to measure temperature in order to determine the degree of readiness of a dish.

Sensor classification

There are several types of sensor classification. We will present the most basic ones.

By type of measurement:

- Pressure Sensors;

- Flow sensors;

- Level measurement sensors;

- Temperature measurement sensors;

- Concentration sensors;

- Radioactivity sensors;

- Motion sensors;

- Angle position sensors;

- Sensors for measuring mechanical quantities;

- Vibration sensors.

Classification by manufacturing technology:

- Elemental sensors;

- Integrated sensors.

Classification according to operating principle:

This includes:

- Optical sensors that use electromagnetic radiation and respond to water vapor, smoke and various types of aerosols. Refers to non-contact sensors. The principle of their operation is based on the detection by a sensitive sensor of the influence of an irritant, for example, water vapor. These sensors are widely used in automated control systems.

- Inductive sensors. They are non-contact sensors and are designed to calculate the position of an object. Inductive sensors are excellent at detecting fluctuations in the electromagnetic field. Their design is based on a generator, which creates an electromagnetic field, the effect of which on a metal object generates vibration amplitudes to which the sensor responds. Such sensors are widely used in metal detectors, as well as in various types of electronic locks.

- Capacitive sensors. These sensors are used in cars as rain sensors, touch buttons on household appliances, and liquid measurement sensors. The principle of their operation is to respond to the influence of liquid. The insulator of such sensors has a dielectric constant. The liquid, acting on the insulator, causes the appearance of an electrical signal, which is converted into information. Such sensors are widely used in household appliances.

- Load cells. Strain gauges are a device for measuring force, pressure, torque, acceleration or displacement. The mechanism of their action is based on the principle of elastic force. Such sensors are widely used in various types of scales. They convert the amount of deformation into an electrical signal, in other words, the sensor detects the impact of any force on it, after which the elastic element is deformed and the resistance of the strain gauge, which is built into such a sensor, changes. Next, the information is converted into an electrical signal and transmitted to another device, for example, a display.

- Piezoelectric sensors. Such sensors are widely used in microphones and sonar. Their operating principle is based on the polarization of the dielectric under the influence of mechanical stress. In other words, piezoelectric sensors detect changes in the electric field that have been mechanically affected. For example, in a microphone this is the influence of the voice. The result of the deformation will be the conversion of the received signal into an electrical one and its transmission to another device. These sensors were born thanks to Jacques and Pierre Curie in 1880.

- Magnetic-electric sensors. These are sensors whose operating principle is based on the so-called Hall effect. These sensors are used in smartphones as the basis for the operation of an electronic compass, in electric motors, and in current meters.

- Nano sensors. Currently under development. The most popular areas for them should be medicine and robotics. It is expected that these sensors will become a new class and will find widespread use in the future. Their operating principle will be similar to many other sensors (hence the names nano-piezoelectric sensors, nano-strain gauges, etc.), but their sizes will be many times smaller

To learn more about sensors, read these articles.

- These are sensors that operate without physical and mechanical contact. They operate through electric and magnetic fields, and optical sensors are also widely used. In this article, we will analyze all three types of sensors: optical, capacitive and inductive, and at the end we will do an experiment with an inductive sensor. By the way, people also call contactless sensors proximity switches, so don't be afraid if you see such a name ;-).

Optical sensor

So, a few words about optical sensors... The principle of operation of optical sensors is shown in the figure below

Barrier

Remember those scenes from movies where the main characters had to walk through optical beams without hitting any of them? If the beam touched any part of the body, an alarm was triggered.

The beam is emitted through some source. There is also a “beam receiver”, that is, the little thing that receives the beam. As soon as the beam is not on the beam receiver, a contact in it will immediately turn on or off, which will directly control the alarm or anything else at your discretion. Basically, the beam source and the beam receiver, correctly called the beam receiver “photodetector,” come in pairs.

Optical displacement sensors from SKB IS are very popular in Russia.

These types of sensors have both a light source and a photodetector. They are located directly in the housing of these sensors. Each type of sensor is a complete design and is used in a number of machines where increased processing accuracy is required, down to 1 micrometer. These are mainly machines with a system H and verbal P programmatic U board ( CNC), which work according to the program and require minimal human intervention. These non-contact sensors are built on this principle

These types of sensors are designated by the letter “T” and are called barrier. As soon as the optical beam was interrupted, the sensor was activated.

Pros:

- range can reach up to 150 meters

- high reliability and noise immunity

Minuses:

- at long sensing distances, precise adjustment of the photodetector to the optical beam is required.

Reflex

The reflex type of sensors is designated by the letter R. In these types of sensors, the emitter and receiver are located in the same housing.

The operating principle can be seen in the figure below

Light from the emitter is reflected from some light reflector (reflector) and enters the receiver. As soon as the beam is interrupted by any object, the sensor is triggered. This sensor is very convenient on conveyor lines when counting products.

Diffusion

And the last type of optical sensors is diffusion - designated by the letter D. They may look different:

The principle of operation is the same as that of a reflector, but here the light is already reflected from objects. Such sensors are designed for a short response distance and are unpretentious in their operation.

Capacitive and inductive sensors

Optics are optics, but inductive and capacitive sensors are considered the most unpretentious in their operation and very reliable. This is roughly what they look like

They are very similar to each other. The principle of their operation is associated with changes in the magnetic and electric fields. Inductive sensors are triggered when any metal is brought close to them. They don't bite on other materials. Capacitive ones react to almost any substance.

How does an inductive sensor work?

As they say, it’s better to see once than to hear a hundred times, so let’s do a little experiment with inductive sensor.

So, our guest is a Russian-made inductive sensor

We read what is written on it

Brand of VBI sensor blah blah blah blah, S – sensing distance, here it is 2 mm, U1 – version for temperate climates, IP – 67 – protection level(in short, the level of protection here is very steep), U b – voltage at which the sensor operates, here the voltage can be in the range from 10 to 30 Volts, I load – load current, this sensor can deliver a current of up to 200 milliamps to the load, I think this is decent.

On the reverse of the tag there is a connection diagram for this sensor.

Well, let's check out the sensor's performance? To do this, we attach the load. Our load will be an LED connected in series with a resistor with a nominal value of 1 kOhm. Why do we need a resistor? The moment the LED is turned on, it begins to frantically consume current and burns out. In order to prevent this, a resistor is placed in series with the LED.

We supply the brown wire of the sensor with plus from the power supply, and the blue wire with minus. I took the voltage to 15 Volts.

The moment of truth comes... We bring a metal object to the working area of the sensor, and our sensor immediately triggers, as the LED built into the sensor tells us, as well as our experimental LED.

The sensor does not respond to materials other than metals. A jar of rosin means nothing to him :-).

Instead of an LED, a logic circuit input can be used, that is, when the sensor is triggered, it produces a logical one signal, which can be used in digital devices.

Conclusion

In the world of electronics, these three types of sensors are increasingly used. Every year the production of these sensors is growing and growing. They are used in completely different areas of industry. Automation and robotization would not be possible without these sensors. In this article, I analyzed only the simplest sensors that give us only an “on-off” signal, or, to put it in professional language, one bit of information. More sophisticated types of sensors can provide different parameters and can even connect directly to computers and other devices.

Buy an inductive sensor

In our radio store, inductive sensors cost 5 times more than if they were ordered from China from Aliexpress.

Here You can look at the variety of inductive sensors.

Until the 70th year of the last century, any car was equipped with a maximum of three sensors: fuel level, coolant temperature and oil pressure. They were connected to magnetoelectric and light display devices on the instrument panel. Their purpose was only to inform the driver about engine operating parameters and the amount of fuel. Back then, the design of car sensors was very simple.

But time passed, and in the 70s of the same century, car manufacturers began to reduce the content of harmful substances in the exhaust gases coming off their car assembly lines. The car sensors necessary for this no longer communicated anything to the driver, but only transmitted information about engine operation to the driver. The total number of them in each car has increased significantly. The next decade was marked by the struggle for safety when using machines, for which new sensors were designed. They were designed to operate anti-lock brakes and deploy airbags during traffic accidents.

ABS

This system is designed to prevent the wheels from completely locking when braking. Therefore, the device necessarily contains wheel speed sensors. Their designs are different. They can be passive or active.

- Passive sensors are mostly inductive sensors. The sensor itself consists of a steel core and a coil with a large number of turns of thin enameled copper wire. In order for it to perform its functions, a steel toothed ring is pressed onto the wheel drive or hub. And the sensor is fixed so that when the wheel rotates, the teeth pass close to the core and induce electrical impulses in the coil. Their repetition frequency will be a proportional expression of the speed of rotation of the wheel. The advantages of a device of this type: simplicity, lack of power and low cost. Their disadvantage is that the pulse amplitude is too small at speeds up to 7 km/h.

- Active, which come in two types. Some are based on the well-known Hall effect. Others are magnetoresistive based on the phenomenon of the same name. The magnetoresistive effect consists of a change in the electrical resistance of a semiconductor when placed in a magnetic field. Both types of active sensors are distinguished by sufficient pulse amplitude at any speed. But their design is more complex and the cost is higher than passive ones. And the fact that they need food cannot be called an advantage.

Lubrication system

Automotive sensors that monitor the operating parameters of this system are of three types:

Engine cooling

A car with a carburetor engine was equipped with two temperature sensors. One of them included an electric radiator fan to maintain operating temperature. The display device took readings from the other. The cooling system of a modern car equipped with an electronic engine control unit (ECU) also has two temperature sensors. One of them uses a coolant temperature display device in the instrument cluster. Another temperature sensor is required for the ECU to operate. Their structure is not fundamentally different. Both of them are thermistors having a negative temperature coefficient. That is, their resistance decreases as the temperature decreases.

Intake tract

- Mass air flow sensor (MAF). Designed to determine the volume of air entering the cylinders. This is necessary to calculate the amount of fuel to form a balanced air-fuel mixture. The knot consists of platinum threads through which an electric current is passed. One of them is located in the air flow entering the motor. The other, the reference one, is away from him. The currents passing through them are compared in the ECU. The difference between them determines the volume of air entering the motor. Sometimes air temperature is taken into account for greater accuracy.

- Intake manifold absolute air pressure sensor, also called MAP sensor. Used to determine the volume of air entering the cylinders. It can be an alternative to a mass air flow sensor for turbocharged engines. The device consists of a body and a ceramic diaphragm coated with a strain-resistive film. The volume of the body is divided into 2 parts by the diaphragm. One of them is sealed, and the air has been pumped out of it. The other is connected by a tube to the intake manifold, so the pressure in it is equal to the pressure of the air pumped into the engine. Under the influence of this pressure, the diaphragm is deformed, which changes the resistance of the film on it. This resistance characterizes the absolute air pressure in the manifold.

- Throttle position sensor (TPS). Produces a signal proportional to the opening angle of the air damper. It is, in essence, a variable resistor. Its fixed contacts are connected to ground and to the reference voltage. And the output voltage is removed from the movable one, mechanically connected to the throttle valve axis.

Exhaust system

Oxygen sensor. This device plays the role of feedback to maintain the desired ratio of air and fuel in the combustion chambers. Its operation is based on the principle of operation of a galvanic cell with a solid electrolyte. The latter is ceramics based on zirconium dioxide. The electrodes of the design are platinum sputtering on both sides of the ceramic. The device begins to work after heating to a temperature of 300 to 400 ◦ C.

Heating to such a high temperature usually occurs by hot exhaust gases or a heating element. This temperature regime is necessary for the conductivity of the ceramic electrolyte to occur. The presence of unburned fuel in the engine exhaust causes the potential difference sensor to appear on the electrodes. Despite the fact that everyone is accustomed to calling this device an oxygen sensor, it is more of a sensor of unburnt fuel. Since the appearance of the output signal occurs when its surface comes into contact not with oxygen, but with fuel vapor.

Other sensors

Electronic sensors (meters) are an important component in the automation of any technological processes and in the control of various machines and mechanisms.

Using electronic devices, you can obtain complete information about the parameters of the controlled equipment.

The operating principle of any electronic sensor is based on converting monitored indicators into a signal, which is transmitted for further processing by the control device. It is possible to measure any quantities - temperature, pressure, electrical voltage and current, light intensity and other indicators.

The popularity of electronic meters is determined by a number of design features, in particular it is possible:

- transmit measured parameters to almost any distance;

- convert indicators into digital code to achieve high sensitivity and speed;

- transfer data at the highest possible speed.

Based on their principle of operation, electronic sensors are divided into several categories. Some of the most popular are:

- capacitive;

- inductive;

- optical.

Each option has certain advantages that determine the optimal scope of its application. The operating principle of any type of meter may vary depending on the design and monitoring equipment used.

CAPACITIVE SENSORS

The operating principle of an electronic capacitive sensor is based on changing the capacitance of a flat or cylindrical capacitor depending on the movement of one of the plates. An indicator such as the dielectric constant of the medium between the plates is also taken into account. One of the advantages of such devices is their very simple design, which allows them to achieve good strength and reliability.

Also, meters of this type are not subject to distortion of indicators due to temperature changes. The only condition for accurate indicators is protection from dust, humidity and corrosion.

Capacitive sensors are widely used in a wide variety of industries. The devices are easy to manufacture, have low production costs, and at the same time have a long service life and high sensitivity.

Depending on the design, devices are divided into single-capacity and spirit-capacity. The second option is more difficult to manufacture, but is characterized by increased measurement accuracy.

Application area.

Most often, capacitive sensors are used to measure linear and angular displacements, and the design of the device may vary depending on the measurement method (the area of the electrodes or the gap between them changes). To measure angular displacements, sensors with a variable area of capacitor plates are used.

Capacitive transducers are also used to measure pressure. The design provides for the presence of one electrode with a diaphragm, which bends under pressure, changing the capacitance of the capacitor, which is recorded by the measuring circuit.

Thus, capacitance meters can be used in any control and regulation systems. In energy, mechanical engineering, and construction, linear and angular displacement sensors are usually used. Capacitive level transmitters are most effective when working with bulk materials and liquids, and are often used in the chemical and food industries.

Electronic capacitive sensors are used to accurately measure air humidity, dielectric thickness, various strains, linear and angular accelerations, ensuring accuracy in a wide variety of conditions.

INDUCTIVE SENSORS

Non-contact inductive sensors operate on the principle of changing the inductance of a coil with a core. The key feature of meters of this type is that they react only to changes in the location of metal objects. The metal has a direct effect on the electromagnetic field of the coil, which causes the sensor to operate.

Thus, using an inductive sensor, you can effectively monitor the position of metal objects in space. This allows the use of inductive meters in any industry where monitoring the position of various structural elements is required.

One of the interesting features of the sensor is that the electromagnetic field changes differently depending on the type of metal, this somewhat expands the scope of application of the devices.

Inductive sensors have a number of advantages, of which the absence of moving parts deserves special attention, which significantly increases the reliability and strength of the structure. The sensors can also be connected to industrial voltage sources, and the operating principle of the meter guarantees high sensitivity.

Inductive sensors are manufactured in several form factors for the most convenient installation and operation, for example, dual meters (two coils in one housing).

Application area.

The scope of use of inductive meters is automation in any field of industry. A simple example - the device can be used as an alternative to a limit switch, and the response speed will be increased. The sensors are housed in a dust- and moisture-proof housing for use in the most difficult conditions.

Devices can be used to measure a wide variety of quantities - for this they use converters of the measured indicator into the amount of movement, which is recorded by the device.

OPTICAL SENSORS

Non-contact electronic optical sensors are one of the most popular types of meters in industries that require effective positioning of any objects with maximum accuracy.

The operating principle of this type of meters is based on recording changes in the light flux when an object passes through it. The simplest circuit of the device is an emitter (LED) and a photodetector that converts light radiation into an electrical signal.

Modern optical meters use a modern electronic coding system that eliminates the influence of extraneous light sources (protection against false alarms).

Structurally, optical meters can be made either in separate housings for the emitter and receiver, or in one, depending on the principle of operation of the device and its field of application. The housing additionally provides protection from dust and moisture (special thermal casings are used for operation at low temperatures).

Optical sensors are classified depending on their operating scheme. The most common type is barrier, consisting of an emitter and receiver located strictly opposite each other. When a constant light stream is interrupted by an object, the device generates a corresponding signal.

The second popular type is a diffuse optical meter, in which the emitter and photodetector are located in the same housing. The principle of operation is based on the reflection of a beam from an object. The reflected light flux is captured by a photodetector, after which the electronics are triggered.

The third option is a reflex optical sensor. As in a diffuse meter, the emitter and receiver are structurally made in the same housing, but the light flux is reflected from a special reflector.

Usage.

Optical sensors are widely used in automated control systems and are used to detect objects and count them. The relatively simple design ensures reliability and high measurement accuracy. A coded light signal provides protection from external factors, and electronics make it possible to determine not only the presence of objects, but also their properties (dimensions, transparency, etc.).

Optical devices are widely used in security systems, where they are used as effective motion sensors. Regardless of type, electronic sensors are the best option for modern control systems and automatic equipment.

High accuracy and speed of measurement ensure proper functioning of the equipment with minimal deviations. Moreover, most electronic meters are non-contact, which increases the reliability of the devices several times and guarantees a long service life even in difficult production conditions.

© 2012-2020 All rights reserved.

The materials presented on the site are for informational purposes only and cannot be used as guidelines or regulatory documents.