Corrugated stainless steel pipe dimensions. Corrugated stainless steel pipes

Read also

This article will introduce you to the main types of finned and corrugated pipes used in heating systems. It's hard to imagine the pipe leading to the battery as anything other than smooth and straight, isn't it? However, surprises await us.

Dictionary

Let's start with a casual introduction to different types exotic pipes. This is necessary to avoid confusion in the future. For our own convenience, we will roughly divide the pipes into categories according to the material from which they are made.

Cast iron

Here we can meet only one representative of the family. Finned heating pipes are massive pieces of cast iron that are hollow inside, on which coarse fins are cast to increase the heat transfer area. They are equipped with flanges for ease of installation and, as a rule, are assembled into registers of varying complexity and size.

It’s interesting: these pipes are used not only as heating devices, but also as heat exchangers that take excess heat from the furnace gases.

Black steel

A convector can be called a finned tube rather arbitrarily - the fins are not made at the same time as it. Transverse plates are pressed onto the finished pipe to increase heat transfer. The heater can be closed at the front decorative screen; An adjustable damper can be located on top to increase or decrease heat transfer.

Stainless steel

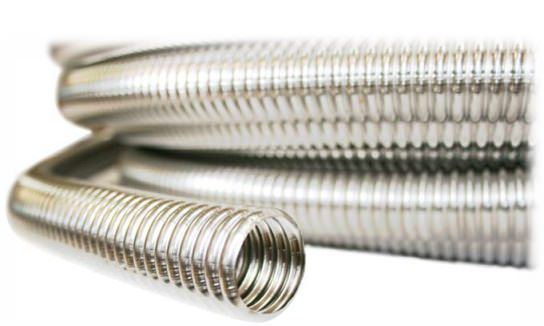

Stainless steel corrugated pipe for heating is a material that appeared relatively recently. The small thickness of the walls ensures flexibility, and the strength of stainless steel ensures a wide range of operating temperatures and pressures.

As an example, here are the parameters with which, according to the manufacturer, Korean corrugated heating pipes Kofulso can work:

- Working pressure - 15 atmospheres.

- The maximum permissible pressure is 50 atmospheres.

- The destruction pressure is 210 atmospheres.

- Operating temperature - from -50 to 110C.

- Minimum bend radius equal to diameter pipes.

Plastic

Flexible corrugated plastic pipe for heating - it would seem nonsense. Plastic does not have high mechanical strength; The corrugated pipe is also thin-walled.

It's simple: the corrugation for heating pipes is not intended for transporting coolant, but for external protection polymer and metal-polymer pipes when laying them in a screed or in-wall installation.

In addition, a corrugated pipe for heating somewhat reduces non-target heat loss.

Attention: do not flatter yourself - it will not replace insulation. If you need to reduce heat loss to a minimum, it is worth protecting the pipes with polyurethane foam shells or at least polyethylene foam.

Corrugated stainless steel: installation method, advantages and disadvantages

If all other materials have been familiar to us for a long time, then we should focus our attention on the corrugated stainless pipe simply because of the relative novelty of the material.

Installation

How to install a heating system from it yourself?

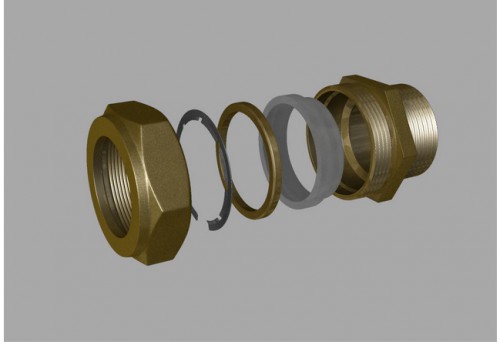

In terms of design, the system does not have any special features and, in principle, is no different from a metal polymer with compression fittings. But the pipes are connected in a different way. For them, fittings without a fitting are used - the pipe is simply crimped on the outside with a gasket made of high-temperature silicone.

The instructions for assembling the connection are extremely simple:

- Cut the pipe in place. It is better to use a special cutter. The price of this device is 700-900 rubles, which is not very much compared to the total cost of heating installation.

- Insert its end into the fitting.

- Tighten the nut on the fitting with gas or wrench. The gasket will tightly seal the pipe, making the connection airtight; corrugation will provide it with strength. Even a very strong person will not be able to tear out the liner section from the fitting.

Advantages

They are very convincing.

- The strength and resistance of the material to pressure surges allows its use in systems central heating together with bimetallic radiators. In this case, the eyeliner will not become a weak link.

- Stainless steel is chemically stable and does not form galvanic couples with aluminum or copper. If one of your neighbors is in common with you heating circuit used copper pipes or put aluminum radiators- none negative consequences It won't matter to you or them.

- The ease of installation of a corrugated stainless steel heating pipe surpasses even the notorious metal-plastic with compression fittings. The tools you need are the simplest - a pair of adjustable or gas wrenches and a cutter, which in principle you can do without. Assembling one connection takes no more than a minute.

- The material has an almost unlimited service life. What’s especially nice is that this period is not reduced when the design temperature of the coolant is exceeded.

Useful: the limit of 110C is quite arbitrary and is associated with the heat resistance of the sealing gaskets, as well as with the thermal expansion of the pipe and fitting. The temperature at which stainless steel noticeably loses strength begins at approximately 800 degrees.

Flaws

There are not many of them.

The appearance of the corrugated surface is, let’s say, not an acquired taste. Metal-polymer pipes probably look better.

The concept of metal fatigue has not been canceled. Stainless steel will withstand a fairly limited amount of deformation. If children constantly swing on the connection to the radiator, sooner or later this will cause its destruction.

Finally, the cost linear meter pipes are quite high: Korean pipes are sold at a price of 170 rubles per linear meter; German - 2-3 times more expensive.

Conclusion

The video at the end of the article will show you more clearly the process of installing a stainless corrugated liner. However, there are no secrets or difficulties in this work. Good luck with the renovation!

Corrugated pipe from of stainless steel, which has maximum durability and a wide temperature range of operation, is best choice for the installation of radiator heating and underfloor heating systems. In aggregate performance characteristics This product is superior to any polymer analogues, and at the same time flexible stainless steel is much cheaper.

This article provides an overview of corrugated stainless steel pipes. We'll look into them functional purpose, specifications, advantages and disadvantages, and study the technology of connecting corrugated pipes.

Contents of the article

Types of corrugated stainless steel pipes

Corrugated stainless steel pipes, depending on the manufacturing technology, are classified into two types - annealed and pipes that have not undergone heat treatment. In practice, the differences between them lie in ductility and mechanical strength - annealed finned tube is more flexible, it tolerates deformation better and can withstand without damage large quantity compression/extension cycles.

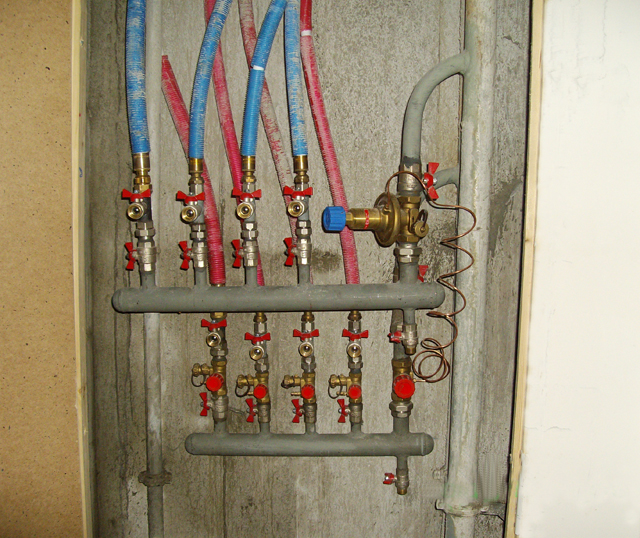

Corrugated stainless steel pipe can be used in systems:

- hot and cold water supply;

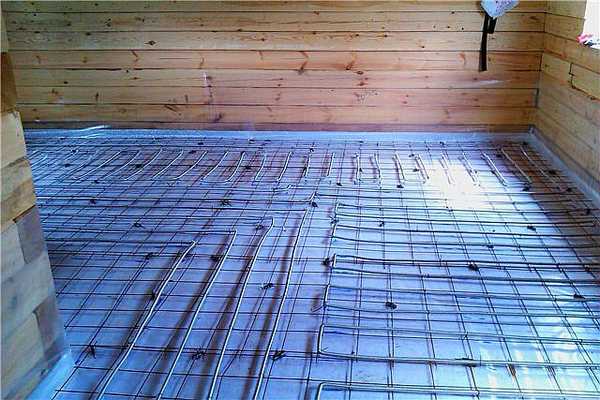

- heated floors, radiator-type heating communications;

- in pipelines for transporting gas and hot steam.

According to GOST requirements, for the manufacture of any types of corrugated pipes must AISI 304 stainless steel used. The production of corrugated pipes is carried out using the following technology:

- a sheet of stainless steel is fed to the production line, which falls into forming machines, where the workpiece is given a cylindrical shape;

- V gas chamber longitudinal welding of the cylinder is performed, due to gases it is achieved minimum percentage burning off alloying components from steel, which ensures the absence of corrosion problems weld during system operation;

- the workpiece is fed into a sizing mill, where it passes through a line of press rollers, giving the product a characteristic corrugated texture.

Upon completion of calibration, finned tubes are considered suitable for use - thus products are manufactured without heat treatment. When implementing the technology for the production of annealed pipes, the corrugated product enters an electric or gas furnace. There, in an oxidizing environment, the pipe warms up to a temperature of 600 degrees. After this, the annealed pipe is subjected to forced cooling.

There are no visual differences between the two types of pipes, however, annealed corrugation has greater strength - creases can form, whereas this does not happen when using heat-treated steel. Annealed products, on average, cost 30-40% more - this is the best option for heated floors.

Advantages and disadvantages

The performance characteristics of corrugated stainless steel pipes place them on a par with more expensive copper products. The benefits include:

- Wide operating temperature range, from -50 to +110 degrees. Pipes can withstand freezing of the circulating medium without damage, which is the main cause of destruction of polymer pipelines.

- Corrugated stainless steel can withstand serious pressure surges in the transported flow, which makes it possible to use it in gas supply pipelines. The maximum pressure for stainless steel products is 50 Bar (for comparison, for plastic ones - 20 Bar), destructive pressure - 210 Bar (at a temperature of 20 0), in heating systems (coolant 110 0) pipes can withstand a pressure of 15 Bar.

- Steel heating pipes made from corrugated stainless steel have high elasticity; they can be used to make pipelines with a minimum number of fittings, which has a positive effect on the reliability of the system as a whole. Bending does not require the use of special tools, minimum permissible radius bending is 3 line diameters(at ∅ 20 mm - 60 mm).

- The service life of steel heating pipes is not limited by their durability, it depends on the integrity of the fittings used to connect the pipes to each other. The service life of fittings reaches 30 years.

- Corrugated stainless steel pipes have smooth walls (roughness coefficient - 0.008), which ensures high hydraulic characteristics of the pipes and noiselessness.

- A stainless steel pipeline is not afraid of linear expansion, which is important when installing a heated floor. The tension in the material is compensated by the corrugated structure.

- Stainless steel is resistant to corrosion due to moisture and is internal walls are not covered with formations and growths that worsen throughput pipeline.

However, corrugated stainless steel pipes also have their disadvantages, which include low resistance to mechanical damage (if the risk is allowed shock impacts, the line must be laid in protective casing) and the impossibility of concreting the pipeline inside the wall, which is also typical for any pipes that are connected using fittings that require periodic maintenance.

Note that stainless steel has high thermal conductivity (17.5 W/mK, polymer products, on average, 0.35 W/mK) which causes significant temperature losses by the coolant during circulation. Laying heated floors or making radiator heating the pipeline must be insulated with thermal insulation material.

Corrugated pipe connection technology

While bending corrugated stainless steel does not present any difficulties and is done manually, to cut pipes into sections of the required sizes you will need special tool— a pipe cutter, the cost of which varies between 1-5 thousand rubles.

The pipe cutter is selected according to the diameter of the pipes used, The standard pipe cutter is designed for products with a diameter of 15, 20 and 25 mm. A pipe cutter can be replaced with a grinder, but in this case you may not get a perfectly even cut, which determines the quality of the connection between the pipe and the fitting.

To join segments together, they are used compression fittings, installation of which is carried out using a wrench.

The technology for connecting corrugated stainless steel pipes is extremely simple to implement:

- using a pipe cutter, the pipe is cut into sections of the required length, the cut point is made with a file or sandpaper cleared of burrs;

- a crimp nut and an o-ring are placed on the pipe;

- the pipe is put on the fitting fitting and the crimp nut is tightened.

In a similar way, the transition from the usual steel pipe on a corrugated one - a fitting is cut into the pipeline, a stainless steel is connected to it and tightened with a crimp nut. When attaching a corrugated stainless steel pipeline to the walls, the increased elasticity of the material must be taken into account; the pitch of the fixing clips should not allow kinks, optimal distance between the clamps - 30-40 cm.

Features of operation of corrugated stainless steel pipes (video)

Features of choosing corrugated pipes and review of manufacturers

When choosing a pipe for a heated floor, pay attention to the pitch of the corrugation - it should be uniform along the entire length of the product, also look at the quality of the weld; the slightest visual flaws (irregularities, notches) can cause pipeline leaks. It is recommended to straighten it several times, so that no deformations or bends should form on it.

It is recommended to connect products using brass fittings, when choosing them, pay attention to the quality of the O-rings, they should be thick enough. It’s easier to choose a pipe cutter - ask the seller to show you the tool in action and everything will become clear, also make sure that the pipe cutter does not have excessive play.

To the market sanitary products Stainless steel corrugated pipes are supplied by a fairly large number of companies. Let's consider the main ones:

- Lavita, a leading manufacturer with a large market share, is distinguished optimal ratio prices and quality;

- Kofulso is one of the first companies to sell corrugated pipes in Russia, the cost of products is higher than that of Lavita, the quality is on average similar;

- Hydrosta - like Lavita, the company occupies the middle price range; consumers often complain about fittings leaking (about 5 pieces per hundred) due to the pressure ring pushing through the pipe walls;

- Meibes - quality products at a fairly high, largely unjustified, price.

Judging by reviews on non-specialized forums, the best option are products from the company Lavita. The company produces the following types products for underfloor heating and heating systems:

- Lavita A - corrugated pipe in diameters 15, 20, 25 and 32 mm;

- Lavita M - fired corrugated pipe, similar dimensions;

- Lavita P - corrugated pipe in a protective PVC sheath, diameters 15, 20, 25 mm (Lavita PM - fired pipe in a PVC sheath).

The company also supplies a range of brass fittings of various configurations (double, angle, tees, crosses) for the installation of pipelines.

Stainless steel corrugated communications are mainly used where short products with a small passage diameter are required. It is very easy to install such pipes in the bathroom, kitchen and boiler room.

Also, this type of plumbing is used for installation of the following engineering systems:

- hot and cold water supply;

- underfloor heating system;

- water heating;

- fire extinguishing and internal gas distribution system;

- channel for electrical cable.

Today, corrugated products can be used not only in newly constructed buildings, but also to replace worn-out structures in old ones.

![]()

Advantages and disadvantages

- Unlimited service life. If a stainless steel pipe can be used for an indefinite amount of time, then O-rings will last about 30 years.

- Installation for minimal amount time. Installation of corrugated communications will not require preparatory work and complex instruments.

- Excellent combination of ductility and rigidity. Despite various mechanical influences, the pipeline system remains as rigid and flexible. Corrugated plumbing fixtures can withstand strong water hammer.

- Flexibility of the material. The pipeline bends very easily without closing the flow area. Such light flexibility does not cause microcracks and mechanical stresses to appear in the metal structure.

- Corrosion resistance. Corrugated pipeline does not corrode and does not leave various deposits on its walls.

- Environmental friendliness of the material. When installing a pipeline for drinking water, no need to pre-process it.

- Durability and reliability. After laying communications, they do not require further supervision, so they can be easily laid under concrete or various decorative panels.

- Original appearance. Corrugated stainless steel products are suitable for any room decoration.

- Ease and simplicity of installation.

The disadvantages of corrugated pipes include their additional insulation when used in chimneys.

Production technology

In the production of corrugated products, two main materials are used: spring and stainless steel foil. In turn, the foil must be wound onto the spring in strips that are connected to each other by special couplings.

Thus, the pipeline becomes flexible and ductile. The quality of the seam must be checked using a laser. To give the material greater flexibility, it must undergo special heat treatment. Final stage production, consists of checking the presence of microcracks in the metal.

This process must take place in liquid medium and under pressure. The pipe can be turned 180 degrees and the length can be increased (can reach three meters).

The best manufacturers

- KOFULSO. A South Korean company that produces multifunctional corrugated products with a unique shape. They can withstand high water pressure and sudden temperature changes. The diameter of these communications ranges from 15 to 50mm. This type of plumbing fixtures is made from steel, on top of which polyethylene is applied. The price for 1 m of kofulso pipe ranges from 150 to 2000 rubles.

- NEPTUN. Russian company, producing stainless steel pipes with a diameter of 15-32mm. This is a universal product with high heat transfer, does not corrode and costs between 85 and 650 rubles per meter.

- INOFLEX. This is a German division of MEIBES, whose range offers products with a diameter from 12 to 40 mm. All products are produced in coils up to 80 meters long. The cost of one meter of pipe ranges from 700 to 2000 rubles. Corrugated pipes from this manufacturer can withstand temperatures up to 200 degrees. This pipe system can be used in solar installations.

- LAVITA. This is a South Korean manufacturer of corrugated stainless steel pipes that can withstand powerful water hammer. Products are produced in annealed and unannealed form, with a diameter of 8-50mm. The price of Lavita corrugated products ranges from 100 to 1100 rubles.

Criterias of choice

When choosing a corrugated pipe, you must remember that it must fit all household plumbing fixtures. First of all, you need to pay attention to the diameter of the products that will fit all home communications.

At the same time, the cross-section of the pipes must be correlated with the power of the entire equipment. An important point when choosing stainless steel products is the grade of steel.

You should also pay attention to the manufacturing technology of products, on the basis of which annealed and unannealed types are distinguished. For example, annealed types are excellent for installation heating system, and unannealed ones are used for the manufacture of connecting elements.

Another criterion for choosing corrugated products is their design. After all, the ability of the pipeline to withstand high pressure depends on the design features.

High-quality corrugated products must have the following parameters:

- holding maximum pressure, which is 50 atm;

- presence of connecting elements;

- holding temperature regime from 50 to 110 °C;

- small degree of elongation (about 2% of the total length of the product).

Installation of corrugated pipelines

To install the pipeline, you will need the following tools: pipe cutter, wrench, clips and drill. The entire installation process takes place in several stages:

- At first you need to cut a piece of pipe to the required length. This can be done with a hacksaw or an electric disk pipe cutter. During the cutting process, it is necessary to ensure that the material is completely smooth, without burrs.

- We join fittings to consuming equipment using sealing materials.

- We give pipe to the desired configuration and tighten wrench union nut until it stops. This way we fix the communication in the fitting.

- Checking installed pipeline for leakage. To do this, you need to supply water and carefully check all pipes. In case of leakage, you need to additionally tighten the union nut using a wrench.

If the pipe has even slight mechanical damage, it can no longer be used for installation.

Selection of fittings

High-quality fittings must have the following technical characteristics:

- Maximum working temperature+200 degrees;

- The pressure range is from 4 to 16 bar;

- The working medium is water, or its mixture with glycol (40%).

Advantages:

- easy and high-quality installation;

- temperature stress compensation;

- application of fittings without the use of special tools;

- reusability in connections;

- the edge does not require additional processing.

It is better to select fittings and corrugated communications made of stainless steel of the same brand.

Corrugated pipe LAVITA

Corrugated pipes for heating are a new product on the market. They were invented in Japan, then they moved to Europe, and now they are conquering our market: the combination of the properties of stainless steel and the flexibility of corrugation turned out to be very successful, and installation is also very easy. Moreover, they can be used completely for wiring the system and only be built in small areas: connections to the boiler, radiators and other elements of the system (replace a leaky piece, for example).

Advantages and disadvantages

This type of material is becoming increasingly popular. And all because many problems are solved at once:

There are many advantages. And they are all valid. Now let's move on to the disadvantages:

As we can see, there are some shortcomings, but they have ways to be eliminated or leveled out, and they don’t look so scary.

How to make a corrugated pipe from stainless steel

The starting raw material is stainless steel metal strip SUS(AISI)304. This strip is fed into forming machines, from which it comes out cylindrical blank. Next, it is welded automatically in the environment of special gases, which prevent the burning of alloying metals (it is they that give the “stainless” properties of steel, and when welding in an oxygen-containing environment, they evaporate, due to which the seams are destroyed in several years, and maybe months, depending on the conditions operation and transported environment).

The resulting pipe can be used and is called unannealed because the next stage is annealing. In this case, the corrugation is heated to high temperatures and then cooled. The result is an annealed corrugated stainless steel pipe. It has better strength characteristics (holds its shape better, the metal becomes more ductile, bends/unbends a large number of times without deformation or destruction), but it is also more expensive. Externally there are no differences, but when bending unannealed products, distortions may appear, but this does not happen with annealed products. It is impossible to distinguish them by appearance, but the lack of markings on the pipes is also disappointing, and how, in fact, can one apply inscriptions to the “wavy” surface. The covers for the coils are marked, but they are easy to replace, and the difference in price can be quite significant. So in this case, you can only hope for the seller’s integrity (well, try bending it several times and see what comes out of it and, based on this, determine the type of product).

In this video, a section of a corrugated pipe is pressure tested. Impressive.

Manufacturers and what to look for when purchasing

There are currently the most Korean companies in our market:

- KOFULSO (“Kofulso”) – according to experts’ reviews best quality, since the first one appeared on the market and has enough great experience production. It has twice the thickness of the seal rings in the fittings, and the weight of the fittings and coils of pipes of the same name is greater. So the increased cost (compared to Hydrosta and Lavita) is justified.

- Lavita (“Lavita”) - performs quite well, but there may be problems in the fittings - sometimes when tightening, the metal ring cuts through the wall (may be due to an installation error - tightening the clamping ring), which causes leaks (per 100 fittings 1-2) - costs less than Cofulso.

- Hydrosta (“Hydrosta” or “Hidrosta”) - in one price category with Lavita, but there are complaints about leaking fittings: per 100 installed, 5-7 pieces leak.

- Neptune (“Neptune”) – characteristics and reviews could not be found;

- Meibes (Meibas) - there are no complaints about the quality, but there are some for the price - very expensive with approximately equal parameters to those given above in the list.

The reliability data was taken from the installer’s post on the forum, this is the result of several years of use: first we worked with Cofulso, then switched to the cheaper Lavita and Hirostat, after replacing fittings and, accordingly, customer complaints, we weighed, looked, and returned to KOFULSO.

What’s good about stainless corrugated pipe is that there are no fakes yet. Maybe because a lot of equipment is required, and the technology is quite complex. Or maybe because the market is just developing, and there is no frantic demand for such products yet.

The video shows the production process of stainless corrugated pipe.

To calculate the volume of the heating system, you may need information about the amount of water contained in a linear meter of corrugated pipe:

- 15mm - 0.219l;

- 20mm - 0.447l;

- 25mm - 71l;

- 32mm - 0.982l.

And about the area of a linear meter of corrugation of the corresponding diameter:

- 15mm - 0.064652m2;

- 20mm - 0.095004m2;

- 25mm - 0.121394m2;

- 32mm - 0.15218m2.

What to pay attention to when purchasing: first, the pitch of the corrugation should be the same, the seam should be even and intact, there should be no chips, cracks or other damage. You can bend/unbend it several times - there should be no deformation or other consequences. When purchasing fittings, also pay attention to the appearance and completeness, Special attention pay attention to the condition and quality of the seal rings. The assortment of fittings is almost standard: all imaginable options are available in nature, but whether they will be available at each specific outlet is a question.

Installation of stainless corrugated pipe for heating

In addition to very good performance characteristics, this material is attractive for the quick and easy assembly of pipelines. All you need is fittings and a wrench. To all heating devices connection is made using them. Select the required type (angle, tee, cross, etc.) and start connecting:

The transition from a regular pipe to a corrugated one occurs in a similar way: first, attach the appropriate fitting to the riser or branch, and then insert a corrugated stainless steel into its other end and tighten the ring. And no special adapters are needed.

The only thing you need to consider when installing corrugated stainless steel is that it is still flexible. Therefore, install fasteners more often than when laying conventional pipe shapes. This will have little effect on the cost - one fastener costs ten or two rubles, depending on the company, and even if you install them twice as often, the maximum that threatens you is an overrun of 200-300 rubles with an average length of the heating line.

Corrugated stainless steel appeared only a few years ago. Therefore, all operating experience amounts to several years. The maximum that we could find on the forums was 7 years. What is typical is no negative reviews– there are no reviews from those who have installed such pipes. There is a lot of negativity from specialists who produce other products from other materials, but they are all theoretical and speculative. Some are more true, others less so. The most plausible drawback is greater resistance than smooth-walled ones. water flow. Although none of those who installed flexible pipes for stainless steel heating, did not note the need for more powerful circulation pumps. For many, this system works with wall gas boilers. Moreover, heated floors and conventional wiring are used.

There is a message from the owner of an apartment in Moscow: he shares his impressions of the installation - just a year and a half ago he changed the wiring: the flight is normal, there are no problems. He also cites the words of the installers, whom he identified as competent specialists (according to the criteria: speed of work + skills). So, they said that they have been installing corrugated stainless steel hoses for 8 years (reported 1.5 years), there were no problems/calls for repairs. When choosing between Kofulso and Lavita, they recommend “Kofulso” - the quality is better.

There are some recommendations (use experience) for “high-temperature” applications in environments above 110 o C. It is advised to periodically, approximately once a year, check the condition of the gaskets. Through specified period Over time they become “woody”. To avoid leaks, it is recommended to replace it (it costs a few rubles), the replacement itself takes a couple of minutes to unscrew, assess the condition and, if necessary, install another one and tighten it. They just recommend not to overdo it when tightening - if you use a wrench, do it without fanaticism at all - high-quality fittings hold well even when tightened by hand, but if the gaskets are pinched, they lose elasticity much faster.

There is experience in using such stainless corrugation in a bathhouse floor screed: two circuits (30m and 15m). One of the pipes is braided (recommended to eliminate problems with the reaction of metal to concrete) and one without - in pure form. There are no problems - they have been lying around for 5 years. Considering the conditions in the bathhouse: very high humidity And heat, periodic freezing/thawing, then corrugated pipes for laying heating in the floor in an ordinary apartment/house can definitely be used, because the conditions are much better than in a bathhouse.

Another owner of heated floors made from stainless corrugated pipes advises doing it according to the principle - one bay - one circuit and not sealing the fittings tightly, but installing combs. He used an unannealed pipe, which he tied to a grate (photo).

There is another warm floor made of 20mm corrugation with a pitch of 20cm. It also operates without problems.

The situation is similar with Kofulso pipe piping and Lavita fittings in the boiler room - for two years of operation there were no accidents or leaks (the fittings were taken from another company due to the fact that they metal gaskets, which seemed to the owner more reliable than polymer ones).

Some even make radiators from it. This is what it looks like (see photo). They say that it heats well, because the heat transfer area is large. It will be problematic to wash such a radiator, but the solution is to install a protective decorative screen.

Results

Judging by the reviews, the picture is even too rosy: no one is complaining. This is even a little alarming. But maybe it’s just that not much time has passed: they began to actively install stainless corrugated pipes for heating just a few years ago and the “sides” have not yet come out. Although, if there were serious problems, they would have already shown themselves, and negative messages would definitely appear: a person is more inclined to describe why he does not like the product than to write about problem-free operation.

Whether or not to install stainless steel corrugation for heating is up to everyone to decide for themselves, but everything looks quite attractive: prices, characteristics and ease of installation. Even the reviews are encouraging.

PROMOTION! WITH 17.07.2017 prices for corrugated stainless steel pipes for fittings have been reduced, please contact our managers for prices.

Depending on the volume of the order, DISCOUNTS are provided!

Check with the managers for details!

|

Name |

Conditional Designation |

Nominal diameter |

Coil length |

Price, |

Price, |

|---|---|---|---|---|---|

| 96,00 | |||||

| 118,00 | |||||

|

Corrugated stainless steel pipe steel, polyethylene coated |

150,00 | ||||

|

Corrugated stainless steel pipe for metal hose |

15AEl |

15 mm |

50 m |

84,00 | |

|

15MEl |

15 mm |

50m |

105,00 | ||

|

Corrugated stainless steel pipe |

165,00 | ||||

|

Corrugated pipe, annealed stainless steel |

195,00 | ||||

| 217,00 | |||||

|

20AEl |

20 mm |

30m |

134,00 | ||

|

Corrugated steel pipe, annealed, for metal hose |

20MEl |

20 mm |

30m |

168,00 | |

|

Corrugated stainless steel pipe |

202,00 | ||||

|

Corrugated pipe, stainless steel steel, annealed |

259,00 | ||||

|

Corrugated pipe, stainless steel steel, polyethylene coated |

- | ||||

|

Corrugated stainless steel pipe for metal hose |

25AEl |

25 mm |

30 m |

171,00 | |

|

Corrugated steel pipe, annealed, for metal hose |

25MEl |

25 mm |

30m |

222,00 | |

|

Corrugated stainless steel pipe |

480,00 | ||||

|

Stainless steel corrugated pipe, annealed |

534,00 |

(A)- flexible pipe for connecting water or gas

Annealed stainless steel corrugated pipe (M)- the pipe is softer in contrast to the corrugated pipe with markings A, malleable to change in shape.

Corrugated stainless steel pipe with polyethylene coating (P)- soft corrugated pipe category M with polyethylene coating, for water or gas.

Corrugated stainless steel pipe for metal hose (AEl)- flexible pipes are used as a cable channel for electrical wiring or other communications.

annealed for metal hose (Mel)- flexible pipes from mild steel, are used as a cable channel for electrical wiring or other communications.

Corrugated pipe A, M, P(except for AEl, MEL - AISI 201) made of high-alloy stainless steel (stainless steel) SUS 304 which allows it to be used in the food industry.