Circulation pump Gilex compass. Compass pumps. The main reasons for the pump not working and options for eliminating them

Circulation pumps are used for heating, air conditioning, water supply and ventilation systems. The units circulate liquid in the network. Thanks to this property, heat or refrigerant spreads throughout the system, maintaining the temperature.

A trusted equipment manufacturer includes the company Gilex, which specializes in the production pumping equipment. The brand of circulation pumps is called Gilex Compass.

1 Purpose

Gilex Compasses are used for forced movement of liquid in the system (heating, water supply, air conditioning). The units do not have the functions of raising water to a height and increasing pressure. The devices are capable of increasing the speed of movement of the working fluid.

In Gilex heating systems, Compasses are used to move water from the heating boiler through the heating element into the system. This maintains and evenly distributes the water temperature in the circuit. Devices with higher power are used in industry, while devices with lower power are used for domestic purposes.

1.1 Model range

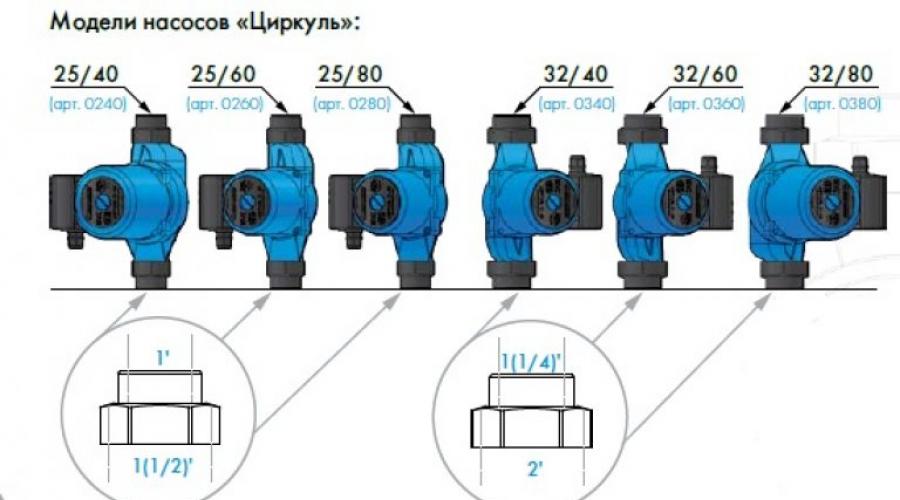

Depending on the cross-section and pressure of the units, there is a division into models. Characteristics of the model ranges:

1.2 How to choose a device?

Selection sequence:

- before you start choosing a circulating device, you need to study information about them;

- the second stage is the required section. The Gilex company produces mechanisms with two section sizes: thirty-two and twenty-five millimeters;

- created pressure. For Compass pumps, the indicator varies from three to eight meters. Therefore, each user will select a pump in accordance with the required indicators;

- choice of rotor type. Devices with a dry type of rotor differ in the coefficient useful action equal to 80 percent. However, they are not durable due to frequent overheating and breakdowns. A wet rotor has an efficiency of fifty percent. Such devices are suitable for private use and have a long service life.

1.3 Pump advantages

Gilex circulation pump has a number of advantages:

- Thanks to the wet rotor, installation of the device does not require additional costs for pressure sensors and protective devices motor.

- Due to their compactness, the devices can be installed in any system.

- The case material is selected in such a way that corrosion does not threaten the device.

- Availability of units. The units can be purchased at any professional store.

- Availability warranty period and service.

1.4 CHARACTERISTICS OF THE CIRCULATION PUMP “CIRCUL” GILEX (VIDEO)

2 Installation

Installation rules and description:

2.1 How to deal with problems?

During operation, breakdowns occur that you can deal with yourself:

- Noisy during operation. The reason is air entering the system or rapid fluid flow. To eliminate this, air is removed or the flow rate is reduced;

- the device does not turn on. The reason is a broken capacitor, lack of voltage. To eliminate this, the integrity of the cable and the voltage level in the network are checked;

- after starting, the device stops. Limescale– the cause of the problem. To eliminate this, wash the device.

2.2 Mark recognition

The units differ in cross-section and pressure. The first number in the model name means the cross-sectional size, the second means the pressure created. For example, circulation pumps Compass 32/40 have a cross-section equal to 3 centimeters two millimeters, the pressure is four meters, and pumps Compass 32/80 have the same cross-section, but the pressure creates eight meters.

Compass units are different high-quality production, reliability and wide model range. The reliability of the pumps is confirmed by reviews.

Modern heating systems come with natural and forced circulation water. The liquid heats up at one point and moves along a closed circuit, giving off its heat to the premises. In this case, each narrowing, linear fittings and pipeline bends create hydraulic resistance. A circulation pump will help to surpass it. It will provide a given speed of movement of the coolant in the network and will allow the use of a heating circuit of any complexity and ramifications.

The effect of using a circulation pump:

- stable circulation and recirculation liquid media free of solid particles and fibers in closed systems;

- uniform temperature distribution in the heating circuit;

- increasing the speed and quality of room heating (radiators in all rooms heat up equally quickly);

- reducing the load on the boiler.

Design, types and principle of operation of circulation pumps

The circulation pump is equipped with an electric motor housed in a steel housing. The rotor transmits rotation through the shaft to the impeller, which creates a vacuum at the inlet pipe by drawing in the coolant. During movement, the blades eject liquid under pressure into heating circuit, which occurs under the influence of centrifugal force. As a result, pressure is created, which is so important for stable and efficient work heating systems.

When choosing, consider the type of circulation pump. They are:

- With a “dry” rotor. Sealed by means of a mechanical seal, used primarily on industrial enterprises, require regular service. Efficiency - 80%.

- With a “wet” rotor. They do not have gland seals. The engine is lubricated and cooled by the fluid being moved. Service maintenance not required, efficiency is about 50%. Scope of application - household systems heating.

It is equally important to consider the following characteristics before purchasing a circulation pump:

- heating area;

- functional features of the heater;

- temperature conditions of premises operation;

- pressure in the circulation system;

- type of coolant used, its viscosity parameters;

- temperature difference between supply and return;

- specific features of the heating system at the facility, pipe diameter;

- technical characteristics of the circulation pump (installation dimensions, performance and pressure, power consumption, housing material, connecting dimensions, number of speeds).

Do right choice Thermal engineering calculation will help. With a well-designed circuit, you will ensure maximum performance and save up to 30% of energy for heating the room.

Features of installation of circulation pumps

The following requirements apply to the installation of circulation pumps:

- The installation site must be freely accessible, protected from cold and well ventilated.

- Closing valves are placed before and after the circulation pump, which will prevent the entire system from emptying in the event of repairs.

- The equipment is placed on the return line in front of the boiler (no air jams, appliances run longer with less hot water).

- The impeller is installed horizontally and operates under the fill; the alignment and direction of the arrow are observed.

- The pipes at the installation site must not be under tension.

- Connection of circulation pumps is carried out in accordance with current rules operation of electrical installations.

Before putting the pump into operation, you must carefully study the passport and strictly follow the installation rules.

The Compass pump is not designed to work with viscous and aggressive liquids, alkalis or acids.

1. The pump is strictly prohibited from being used without water. This is due to the fact that the pump is cooled by the liquid flowing through it. When used without water, the pump's ceramic bearings will wear out quickly. As a consequence, this will lead to Working wheel will stop. In addition, wear of ceramic bearings cannot be repaired under warranty.

2. In order for the device to operate without problems and noise, it is necessary to provide it with normal operating conditions, namely:

- The pressure at the outlet of the water column must be at least 9 m.

- Temperature - no more than +110 C

Main parameters of the Gilex Compass pump

The Gilex heating circulation pump can operate in some modes, switching between which occurs exclusively manually.Advantages of working with such a switch:

- Energy saving;

- Reduced level of operational wear;

- Minimum noise level.

Device installation

The Compass pump can only be installed in a well-ventilated and warm room. In cold conditions, the device may not work correctly or may not work at all.It is important to note that the Compass pump can only be used when welding and other work on the heating system is completely completed.

The manufacturer recommends installing closed valves not only before, but also after the pump. This will help avoid water leakage if the pump itself is replaced.

The pipes must be installed in such a way that the pump does not experience pressure from them due to their mass. In addition, the pipes should not be initially under tension.

The Gilex Compass pump is installed directly into the pipeline. Thus, the axis of the circulation pump will be coaxial with the pipeline.

The compass is only allowed to be placed in a flat part of the pipeline. This will avoid unnecessary vibrations and noise during operation.

There is an arrow on the Gilex pump body that indicates in which direction the coolant will move. Therefore, the flow of coolant must follow the direction of this arrow.

It is best to have the pump at hand or installed in convenient location. Thus, if necessary, he will always be there and you won’t have to waste time on preparatory work or repair.

The circulation pump is installed so that the coolant cannot damage the motor of the device.

Start of operation

Each Compass pump is equipped with a rotor that operates in water. The rotor is installed by the manufacturer in special bearings, so before starting work with the device, it is necessary to bleed air from it and pour coolant into the pump.Important! When releasing air from the device, you need to be careful and attentive. It is then necessary to ensure that water from the pump does not fall on its electrical elements. This important point safety precautions.

Air is released from the pump as follows:

WITH reverse side The electric pump motor has a bolt that needs to be unscrewed.

You will be able to literally immediately notice that the air gradually begins to escape. As soon as all the air is released and water begins to flow out of the pump, the bolt must be quickly returned to its place, tightened tightly.

The valves on both sides of the pump must be opened.

During operation (depending on the system), the pump can become very hot in a very short time.

Remember! Pumping out air and turning on the pump should be done at low speeds.

For safe operation device, and also for personal safety, it is not recommended to touch even the pump housing during operation. This will protect you from possible burns.

Speed setting

As already mentioned, the Gilex Compass pump operates in several speed modes. There are three of them. Switching between modes is possible thanks to a switch located directly on the body.

Before preparing the Compass pump for operation, it must be completely disconnected from the network. It is also important to ensure that an unauthorized person does not have access to turn the device on and off.

After you notice that the pump has become very hot during operation and has reached its maximum speed operation, it must be turned off immediately and wait until it cools down completely.

Failure to follow these safety instructions will result in consequences and injury.

Under normal operating conditions, the device does not require repair or even maintenance for many years.

If Compass for a long time is not used, it may become blocked. But this does not mean that it can no longer be used.

The manufacturer offers an unlocking scheme that will allow you to get the most out of your device in the future.

Unlock scheme:

1. Turn off the pump, disconnect from the electrical network2. Unscrew the valves on both sides

3. Unscrew (completely) the bolt for pumping out air

4. Take a screwdriver, insert it into the shaft, and turn it until the shaft turns freely

5. Now you can return the bolt to its place.

The Gilex Compass pump is strictly forbidden to be used by people who have no experience, people who have not been instructed, and also children.

The main reasons for the pump not working and options for eliminating them

1. The most common problem that a user may encounter is the device simply not starting. If the Compass pump does not start, the reasons for this may be:- Absence electrical voltage;

- Lack of power supply;

- Rotor blockage due to plaque;

- Non-working capacitor.

- Check the presence of power and voltage in the network, check the pump cable for faults.

- Try to unlock the circulation pump using the method described above.

- Try turning on the device at first speed.

- If all else fails, contact service center for professional help.

2. Another problem that may arise is the high noise level of the pump.

The reasons for this may be the following:

- There is a lot of water in the pump that it cannot handle.

- Air was not completely released before operation and entered the system.

- Set the minimum operating speed.

- Bleed the system completely

- The excess air that got into the system was, again, not completely pumped out before the heating circulation pump started operating.

4. Another common problem is the situation when, after starting the pump, it immediately turns off without starting to perform its functions.

The reason for this is the layer of plaque that has formed between the rotor and stator. In addition, plaque can form between the device body and the pump impeller.

To fix the problem you need to:

- Completely disassemble the circulation pump.

- Rinse it thoroughly, getting rid of plaque.

Gilex circulation pump reviews indicate that users are completely satisfied with the functions that the device performs, as well as its high-quality, silent and efficient operation.

You can buy a Compass pump in any professional store or online store.

Gilex Compass pumps are used for pumping hot water or coolant in heating systems. Moreover, these pumps can be used for transportation cold water in systems not associated with drinking water supply.

Design and operating principle

The main design elements of the circulation pump are shown in the figure.

Pump Compass, like most centrifugal pumps, does not have self-priming, that is, before starting it must be filled with liquid. When power is supplied to the drive motor 1, the rotor 2 begins to rotate, which is connected to the shaft 3, driving the impeller 4, which acts on the liquid, directing it from the suction channel 5 to the discharge line 6. The structural elements are located in a collapsible housing 7.

Characteristics of pumps Compass

Let's look at the main characteristics of the Compass series pumps.

Connection size and maximum pressure.

Pump characteristics Compass 25-40

The figure shows the flow characteristics of the Compass 25-40 pump.

Pump characteristics Compass 25-60

Pump characteristics Compass 25-80

Pump characteristics Compass 32-60

Pump characteristics Compass 32-80

Installation dimensions

The installation size of Compass pumps is 180mm.

Installation and maintenance of pumps Compass

Circulation pumps may be installed in the following positions.

Do not install pumps in the following manner.

All circulation pumps must be primed before starting. To completely fill the pump, you can unscrew the plug.

Possible problems

Pump noise

The causes of noise may be:

- Increased fluid resistance in the pipeline

- Air in the pump

In the first case the noise may be caused by too much high speed currents, in this case, you can (if the system allows it) reduce the speed by switching the corresponding switch on the pump.

Also, the presence of air in the heating system can create noise. In this case, it is necessary to remove air from the system.

The second common cause of noise is the presence of air in the pump. In this case, you need to fill the pump with water, unscrew the plug, and wait for the water to flow out. When performing these actions, it is necessary to de-energize the pump and secure electrical connections from getting wet. Be careful the system may be full hot water. When working with the pump, generally accepted safety standards must be observed.

Circulation pumps Gilex Compass provide accelerated movement of the coolant in heating system, which prevents the water in the pipes from cooling until it returns to the boiler. This eliminates the need to reheat it. In addition, the settings ensure that the room warms up much faster with an even temperature distribution.

Technical Advantage of Jeelex Product

If we compare the design Compass with competitive equipment similar in action and purpose, with which this market segment is crowded today, you can see a certain superiority:

- economical electricity consumption;

- the presence of a three-speed special switch ensures low noise reproduction;

- both the housing box and all nuts are made of materials that are not susceptible to corrosion;

- air deflates easily because pumps have a corresponding built-in valve.

Models of installations of this line Gilex It is advisable to use it in relation to old-type communications, where the main lines consist of a pipeline of impressive diameter. Without outside help it will not be possible to ensure natural full circulation. But this problem is completely solvable with this unit.

Circulating The device forces the coolant into the desired movement forcibly. Acceleration (speed) is calculated in such a way that the coolant in the system, when returning from the pipes to the boiler, has a temperature of maximum performance. Thus, owners of premises (residential and non-residential) save money on heating.

How to choose the right product

Before buying pump type units famous manufacturer from this series, you need to think through a certain list of parameters. Particular attention should be paid to:

- power indicators;

- connecting dimensions;

- dimensions in general;

- electrical energy consumption;

- functionality: there are various modifications of products provided within the same line. They all have their own optional kit. This will help you choose the required device that matches your needs and capabilities.

Do not forget about such indicators as the size of the heating area, individual characteristics heating systems, in particular pipe diameter, differential temperature regime between water supply and return. Correctly made calculations in terms of selection and competent circuit design will help you save about thirty percent on heating (a fact confirmed reviews users).

You can ask questions in the online chat. You can buy a suitable variation of the unit from us at affordable price. Descriptions and parameters of each product are in the catalog.