Heating circulation pump with flow sensor. Water flow sensors for gas boilers and pumps. Devices with three cameras

A water flow sensor is a device that regulates the pressure inside a water supply system. It is connected to the pumps through pipes. The main parameters of devices should include not only the maximum pressure, but also output voltage. Manufacturers also indicate without fail throughput. Today there are many types of modifications. To understand the issue in more detail, you should first study the design of the water flow sensor.

Model device

The standard water flow sensor circuit includes a relay and a set of plates. Inside the modification there is a wide chamber. The flask is always stationary. There is a small float inside it. There is a feed channel at the outlet. Many modifications are made with an adjustment valve, which is installed at the outlet. Models with valves are equipped with movable fittings. They use magnetic force to operate.

Sensor: do it yourself

Making a water flow sensor with your own hands is quite simple. First of all, it is recommended to install the camera. A small one will do for this. plastic container. Then you will have to cut three plates that are installed in a horizontal position. Ultimately, the flask should not come into contact with them. If we consider simple model, then one float is enough. It is more expedient to install the fitting on two adapters. The valve must withstand a pressure of at least 5 Pa.

Types of modifications

By design, only relay and fitting devices are distinguished. Additionally, modifications are divided according to pressure level. Devices for circulation pumps are included in a separate subcategory.

Relay models

Relay water flow sensor for gas boiler Suitable for low power pumps. As a rule, models are produced with one camera. Many experts say that they have low conductivity. However, it is worth noting that there are devices with vertical arrangement plates Their maximum pressure is at least 5 Pa. Protection systems are quite often used in the P48 series. All this suggests that water leaks are rarely observed. The modifications are characterized by excellent stability. Their suction force is at least 3 N. Faucets are very rarely found in models.

Fitting devices

The most common devices for pumps are fitting modifications, which are produced with a single chamber. Their plates are usually located in a horizontal position. Some modifications are equipped with two valves. And their maximum pressure parameter is approximately 5 Pa. Protection systems of the P58 class are quite often used. In this case, the conductivity depends on the size of the fitting. Some modifications can boast high speed pumping. Their connections are quite often of the threaded type. There are also clip-on sensors on the market, which are not very popular.

Low pressure devices

Modifications low pressure Well suited for centrifugal pumps up to 4 kW. Their conductivity depends on the size of the chamber. The most common type on the market is a water flow sensor for a two-float pump. In this case, the pumping force averages 5 N. Protection systems are used different classes. Many sensors are installed through pads. The output contacts are designed for wire adapters. It's also worth noting that there are many inexpensive models on the market.

High pressure modifications

Models high pressure, as a rule, are produced with one oblong fitting. The plates on the water flow sensor for the pump are most often installed in a horizontal position. If you believe the reviews of experts, the models are excellent for centrifugal pumps. When choosing a modification, it is important to pay attention to the throughput of the devices. The dimensions of the devices are also taken into account. Many models are produced with two cameras. However, they only use one valve. If we consider the standard model, the maximum pressure on average is no more than 6 Pa. The protection system in the devices is of class P70. It is very rare to find models with a tap. Basically, conventional switches are installed.

Devices for circulation pumps

Sensors for circulation pumps are in great demand. Distinctive feature modifications are considered to have low reducibility. The maximum pressure is on average 3.3 Pa. Protection systems are used most various classes. Devices with two cameras are very rare. When choosing a model, it is important to pay attention to the shape of the fitting. It should have a wide head and a narrow channel. Otherwise, leaks will occur frequently. Additionally, it is worth noting that float-based devices are available on the market. Their contacts are designed for adapters.

Features of models with two cameras

Sensors for two chambers, as a rule, are distinguished by their large dimensions and high pressure parameter. There are many two-valve models on the market. They have a suction force of 4 N. Protection systems are used in the P88 series. The sensor plates are always installed in a horizontal position. If we talk about the disadvantages of devices, it is important to note that they use very large output channels. The models are not uniquely suitable for pumps with a power of up to 8 kW. There are devices on the market with and without taps. Additionally, there are modifications based on contactor switches.

Devices with three cameras

Sensors for three chambers are connected for centrifugal pumps. Their ultimate compressive force is very high. It is also worth noting that models are produced with short channels. Their valves are of the rotary type. They are protected by a special membrane. According to experts, conductivity depends on the size of the chamber. If we talk about designs, it is worth noting that there are models on the market with elongated fittings. They have extremely low suction power. However, they can last a long time. Devices with switches are very rarely found in stores. As a rule, three-chamber models are produced with small taps.

Models for low-power pumps

A water flow sensor for low-power pumps should be selected only among fitting modifications. Its maximum pressure indicator should be about 5 Pa. The protection system is of class P48. Many experts praise devices based on two cameras. Their suction force is approximately 4 N. Relay modifications for low-power pumps are not the best fit.

Modifications with vertical plate arrangement

Devices of this type perform well on centrifugal pumps. They have good conductivity and no problems with high blood pressure. However, do not forget about the disadvantages of modifications. First of all, their channel is often clogged. If we consider an inexpensive water flow sensor, then it may have problems with the valve. For normal operation of the system, it is more advisable to select devices with 12 V output contacts. The protection system must be installed to class P55. Experts also say that the water flow sensor should have a contactor switch.

Devices with horizontal plates

The water flow sensor for a boiler of this type is suitable for a wide variety of pumps. The conductivity of models depends on the dimensions of the chamber itself, as well as the channel. Additionally, the diameter of the fitting is taken into account. Many experts recommend installing two-chamber modifications. Their pumping force, as a rule, does not fall below 5 N. The protection system is quite often used in the P50 series. All this means that the manufacturer guarantees high degree sealing and overall reliability.

When choosing a device, it is important to evaluate the valve parameters. If it is made of ordinary plastic, then it is not able to last long. Copper analogues perform well, but are expensive. The main bulb of the sensors is made of plastic. Modifications with transition contacts are very rare. Relay modifications can boast high conductivity. They are not afraid of overloads. And they are used quality systems protection.

Now we will figure out why a water flow sensor is needed (also called a “flow switch”) and look at the principle of its operation. You will also learn what types of these sensors there are and how to install it yourself.

Find out the price and buy heating equipment and related products you can find here. Write, call and come to one of the stores in your city. Delivery throughout the Russian Federation and CIS countries.

In everyday life, sometimes an emergency switching on of a pump without water occurs, which can lead to equipment breakdown. Due to the so-called “dry running,” the engine overheats and parts are deformed. In order for the pump to function with maximum efficiency, it is important to ensure the water supply without interruption. To do this, you need to equip the heating and hot water supply system with a device such as a water flow sensor.

Water flow sensor

Design and principle of operation

A water flow sensor is a device that monitors the pressure inside the water supply system; it is connected to the pump via pipes.

Standard circuit of a water flow sensor:

- relay;

- set of plates;

- There is a wide chamber inside the device;

- float small size, which is placed inside a stationary flask;

- outlet feed channel;

- Most models are equipped with an adjustment valve installed at the outlet.

Operating principle of the sensor: when there is no liquid flow, it automatically pauses pumping station and does not allow dry running, and when water appears, it starts the device.

Application area

Water flow sensors are usually found in devices where it is necessary to constantly monitor the life support system and observe a certain operating mode.

Most often, water flow sensors are used in boilers operating on gas. Modern gas boilers equipped with such sensors are used for both heating and water heating.

Device located on the supply line tap water when water enters, it sends a signal to the boiler control board and operation circulation pump stops. Then the board turns on the nozzles responsible for heating running water, and the water in the heat exchanger begins to heat up. When the tap closes, the sensor notifies that the water supply has been stopped.

Most households are equipped with systems autonomous water supply, thanks to which you can have the most comfortable conditions.

The function of the water flow sensor is that when you turn on any of the devices connected to the water supply system, the sensor turns on the pump and water begins to flow.

When choosing a water flow sensor, be sure to consider the throughput of the devices and their size.

Types of water flow sensors

According to the type of design, relay and fitting devices are distinguished. In addition, there are varieties based on pressure levels.

Relay type water flow sensor used for pumps with low power. Typically these models are single-chamber. Experts note their low conductivity. Models with a vertical arrangement of plates are available, their maximum pressure is at least 5 Pa.

Protection systems are often used in the P48 series. Thanks to all these indicators, there are practically no water leaks, and such devices are also characterized by good operating stability.

The most widely used water flow sensors for pumps are fitting models. Their plates are usually placed horizontally, and some samples are equipped with two valves. Maximum pressure they have approximately 5 Pa. Protection systems are most often class P58. Conductivity is directly dependent on the size of the fitting.

Low pressure sensors are applicable for pumps with a power of no more than 4 kW. The size of the chamber affects the conductivity. Most often on the market you can find a water flow sensor for a pump with two floats. Their price is low and you can easily choose the right model.

High pressure models are usually available with one extended fitting, the plates are mounted horizontally. Experts advise installing such samples in centrifugal pumps. Maximum pressure does not exceed 6 Pa, protection system class P70.

Also, according to the mechanism of action, it is divided into:

- a water sensor based on the operating principle of a Hall sensor: it signals not only the flow of water, but also the speed of its supply;

- a reed switch sensor operating on the principle of a magnet: inside it there is a magnetic float, which, as the water pressure increases, moves around the chamber and affects the reed switch.

Design and principle of operation of a reed switch water flow sensor

DIY installation and manufacturing

Most water flow sensors are included in the design of the devices, so they need to be installed only in the event of a breakdown and the need to replace them. However, there are cases when the water flow sensor must be mounted separately, for example, if it is necessary to increase the water supply pressure. This is due to the fact that in the system central water supply, the pressure is low and does not reach the norm. And in order to turn on a gas boiler in hot water supply mode, you need good pressure.

In such situations, an auxiliary circulation pump , which is equipped with a water flow sensor. First the pump is installed, and then the sensor. It follows that as soon as water starts flowing, the sensor will turn on the pump and the pressure will begin to increase.

Pressure booster pump for Grundfos UPA 15-90 water supply system with built-in water flow sensor

Making a water flow sensor with your own hands is not difficult. First you need to install the camera, then you need to cut out three plates, they should be mounted horizontally, there should be no contact between them and the bulb. For a simple design, one float will be enough.

It is rational to install the fitting on two adapters; the valve must withstand a pressure of at least 5 Pa.

Manufacturers

| Manufacturer | Characteristic |

|---|---|

| Water flow sensor for Grundfos pump UPA 120 (Denmark) | Designed to provide water supply individual house, apartments equipped individual system water supply The sensor automation is turned on when steady flow liquids in the range of 90-120 liters per hour. The main function is to protect the pump from idling. The pump starts at a water flow rate of 1.5 liters per minute. The operating voltage of the sensor is 220-240 V. Maximum current consumption is 8 A. Power consumption – up to 2.2 kW. Degree of protection - IP 65. Price - about 1,800 rubles. |

| Water flow sensor GENYO - LOWARA GENYO 8A (Poland) | Used to control the pump household system water supply based on actual water consumption. The main feature of the sensor is to monitor the pressure in the water supply system during operation. The pump starts at a water flow rate of 1.5 liters per minute. Operating voltage – 220-240 V. The frequency of current consumption is 50-60 Hz. The maximum current consumption is 8A. Power consumption – up to 2.4 kW. Operating temperature range - 5-60 degrees Celsius. Degree of protection - IP 65. Price - about 1,800 rubles. |

| Flow sensor 1.028570 (Italy) | Designed for installation in gas double-circuit boilers trademark Immergas. Compatible with models: Mini 24 3 E, Victrix 26, Major Eolo 24 4E | 28 4E. Designed for installation in gas boilers Immergaz trademark chimney and turbocharged versions. Made in a plastic case with a threaded connection. The Hall sensor 1.028570 allows you to obtain water at a stable temperature at the outlet of the hot water supply circuit. Price - approximately 2,400 rubles. |

Thus, the water flow sensor is designed to protect the operation of boilers and pumping equipment.

general description

The Grundfos UPA water pressure booster pump is a sealless pump with " wet rotor". For pumps with a “wet” rotor, the motor is completely immersed in the pumped water, which lubricates the parts and at the same time cools the engine.

The UPA pump's electric motor is cooled by the pumped liquid and, thanks to well-absorbed vibration, the pump operates silently.

The electric motor of this pump is separated from the stator by a protective sleeve made of of stainless steel. The unique ceramic bearing system gives the UPA pump unsurpassed durability and reliability.

The pumps are available in two versions:

- with a cast iron body having an internal anti-corrosion coating(UPA 15-90);

- with stainless steel housing (UPA 15-90 N).

Example UP A 15 - 90 N 160

Type range - UP

Automatic start/stop via flow switch - A

Nominal diameter of suction and discharge pipes (DN), [mm] - 15

Maximum pressure [dm] -90

Housing version - Cast iron N - stainless steel

Key Features and Functions

- Operating range Delivery up to 1.5 m3/h

- Head up to 8 m

- Supply voltage 1 x 230 V

- Temperature of the pumped liquid from 2°C to + 60°C

- Temperature environment from 2°C to + 40°C

- Max. operating pressure 6 bar

- Connection G 3/4"

- Protection class: IP 42.

- Insulation class: H.

- The pump is equipped with a cable.

- The electric motor is equipped with short circuit current protection.

- The pump noise level does not exceed 43 dB, which corresponds to EEC

UPA circulation pumps are designed to increase pressure in existing system water supply for private houses, apartments, etc. First of all, they are used to create pressure in front of water heaters ( geysers And instantaneous water heaters), washing and dishwashers. Compact UPA pumps can also be used to increase water pressure in showers or other water points.

UPA water pressure booster pump are used in open systems, and can also be connected directly to the water supply network.

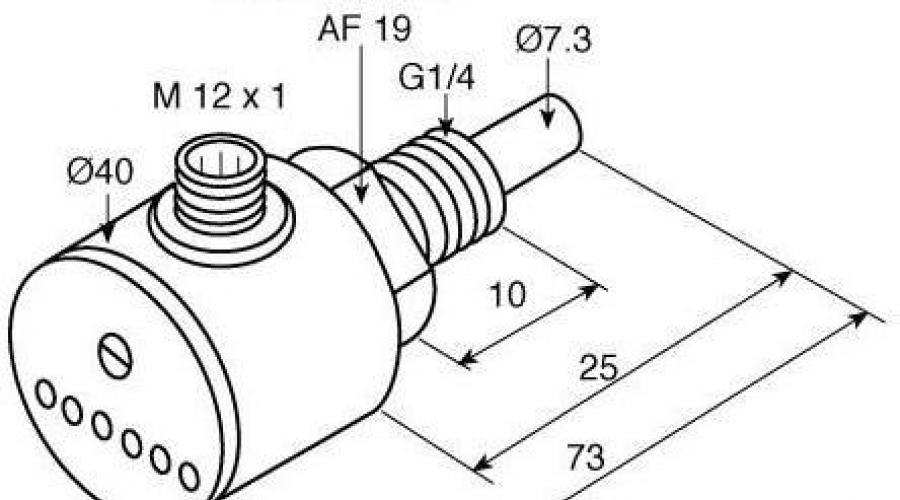

UPA 15-90 (N) are equipped with a flow sensor to automatically turn on/off the pump when the tap is opened at the water collection point. To provide additional protection The electronic unit is equipped with a built-in temperature sensor. When overheating, the engine turns off; when the temperature decreases, the motor automatically turns on.

Using a switch on the terminal box, the pump is set desired mode work. The small dimensions and weight of the pump allow it to be mounted directly on pipelines.

Add. Information

Grundfos UPA pumps are designed to require no additional effort. maintenance, and will not cause difficulties in care.

The high-quality performance of pumps in the UPA model line is confirmed by certificates and has a quality guarantee.

The main task of any water supply system is not only to provide water to the consumer, but also to ensure its uninterrupted operation in automatic mode without breakdowns. The commonly used pressure and dry-running switches and float devices for controlling the liquid level are designed for this purpose. In addition to automating the operation of the system, these devices protect the pump from dry running and, as a consequence, from overheating and failure. Water flow switches for the pump are less known and widespread, but are also designed to automate the operation plumbing system and protect its main equipment from failure.

The flow switch is designed to monitor the flow of liquid in cold and hot water supply systems, heating systems, treatment and cooling plants.

Its main purpose is to protect electric pumps, motors and other devices from operating in conditions of absence or small amount of water in the system, leading to overheating and equipment failure.

Fig.1 External view of the flow switchThe relays are designed for installation in pipelines and allow you to automate the process of controlling the supply of liquids in systems for domestic and industrial use.

The water flow sensor for the pump is used in the following cases.

- If the system does not have a hydraulic accumulator. This does not allow the installation of a pressure sensor designed to work in conjunction with expansion tank, to protect the electric pump it is better to use a flow sensor.

- In low pressure systems. The minimum response threshold for standard models of pressure sensors is 1 bar, that is, at a lower pressure in the system, the pump will always be turned off. Flow devices have a wider spectrum of action, which can be expanded through adjustments. This allows the devices to be used to protect equipment in systems with reduced pressure.

To adjust to work with a wide range of pressures, some petal models are equipped with petals different sizes, providing different resistance water flow. Sometimes notches are applied to the blade indicating the length. During installation, it is cut to obtain the required response pressure according to the table with various combinations petal length and inner diameter of the pipeline.

Figure 2. Flow relay with adjustable blade length

Figure 2. Flow relay with adjustable blade length - The vast majority of flow relays are designed to operate in heating systems, therefore the temperature of their working fluid can be 100 C or more.

Design and principle of operation

The operating principle of the flow switch is based on the mechanical effect of the water flow in the pipeline on the sensor that controls the electronic circuit for turning on and off the electric pump. Relays have different principle work and depending on the design of the sensor are divided into several types.

Petal relays

One of the most common types, the main elements are a petal sensor with a magnet located in the water flow and a reed switch placed in the device body and securely insulated.

Fig.3 Petal mechanical relay

Fig.3 Petal mechanical relay When a water flow passes through a pipeline, a vertically located petal sensor rotates along its axis and deviates from vertical position, bringing the built-in magnet closer to the reed switch. Its contacts inside the cylinder are closed and the pump is connected to a source of electricity through a triac (double symmetrical thyristor).

If there is no water in the pipeline, the petal returns to its original position, moving the magnet away from the reed switch and thereby opening its contacts.

This leads to the cessation of supply voltage to the pump through the semistor, as a result of which it turns off.

Fig.4 Appearance of a relay with a reed switch and a semistor

Fig.4 Appearance of a relay with a reed switch and a semistor Rotary relays and flow type sensors

Rotary sensors are mainly used to measure and control fluid flow. Structurally, they are made in the form of a paddle wheel rotating in a fluid flow, its rotation speed is recorded touch sensors. Electronic circuit allows for analog, frequency or discrete control of equipment operation.

Fig.5 Rotary sensors

Fig.5 Rotary sensors Piston devices

The piston is placed in the valve seat and, under the influence of water pressure, moves in the vertical direction to a height proportional to the force of the flow. Permanent magnet, mounted on the piston, approaches the reed switch and the contacts close in it. Piston devices can be installed on horizontal and vertical pipelines thanks to the built-in return spring that returns the piston to initial position when there is no flow.

Rice. 6 Operating principle and appearance piston relays

Rice. 6 Operating principle and appearance piston relays Water flow switches, unlike pressure switches and dry running switches, float switches, are not so widely used for automatic control water electric pumps in systems domestic water supply. This is due to the fact that they cannot work independently in the water intake system - to turn them on, it is necessary to create a water flow and turn on the pump by other devices. Relays are designed to turn off electric pumps and are often built into electronic water supply control units together with other automation.

To extend the life of liquid flow devices, it is recommended that they be regularly inspected, refurbished and major renovation. But sometimes this is not enough for the pumps to work smoothly. A water flow sensor will come in handy. The protection relay prevents damage to the motor of surface and deep-well pumping equipment. Let's consider the types of equipment, conditions correct selection and do-it-yourself installation and adjustment technology.

In domestic water supply systems, there is a problem of lack of water, which leads to “dry running”. The incoming liquid cools the system elements, serves as a lubricant and provides normal work. If there is no water, the system runs dry, causing deformation and breakage of parts, and equipment failure. The problem occurs in pump models of any configuration.

Causes of dry running:

- incorrect choice of pumping equipment performance;

- violation of installation technology;

- deformation, pipe break;

- reduced water flow pressure;

- lack of control over the liquid level;

- debris in the pumping pipe.

An automatic or mechanical water flow sensor for the pump is needed to eliminate the threat of dry running. The device carries out measurements in a given mode, carries out control and maintains a constant level water flow. If a failure occurs in the station system, the sensor is triggered, the pump turns off in independent mode, and when the flow level resumes, it turns on.

Types of water flow switch

The most common water flow switch configuration for a pump is a petal switch. The classic circuit of the device consists of the following elements:

- inlet pipe;

- valve (petal) located on the wall of the inner chamber;

- isolated switch;

- springs of a certain diameter.

The reed switch opens and closes the power supply circuits that operate the compression spring. The principle of operation of the sensor in a water flow: when the chamber is filled with liquid, the flow forcefully displaces the valve from its axis, affecting the magnet, which operates the switch. The contacts close and the pump turns on.

There are several types of sensors with their own operating characteristics and application possibilities.

Mechanical paddles

The device is a device equipped with a blade that is built into the pipeline. The principle of operation is standard: when a flow enters, the blade deflects and acts on a magnet. The contacts close, the switch sensor is activated. The simplicity of the unit explains the wide range of applications. In addition, such sensors are practically not subject to wear and do not require maintenance - there is nothing to break in them.

Mechanical piston

The device operates on the basis of a magnetic piston system. Operating principle: when a flow enters, the piston with a magnet rises, closing the contacts - the relay is triggered to start. Without flow, the piston drops to its original position, preventing dry running. The main advantage of the device is the variety of designs that allow the device to be mounted in any position. Mechanical piston relays are used in high pressure systems.

Thermal

The device is equipped with a meter for the level of thermal energy dissipation from the built-in heating element. Depending on the change in the heating rate of the liquid, the flow itself and its flow rate are recorded. The thermal sensor is used only for safe species liquids. Due to the use of the hot-wire principle, it is prohibited to use the relay to measure flammable substances, as well as liquids that change composition when heated.

Advice! When choosing a device, you should remember that not all units operate with constant changes in flow. Thermal sensors require cleaning of sensitive elements.

Ultrasonic

The universal pulse water flow sensor operates on the principle of the acoustic effect. The device transmits an ultrasonic pulse through the flow, determining the liquid level. The most common are products whose functionality uses the movement of vibrations of a moving fluid. The devices are suitable for any substances, including flammable ones, and are easy to install and maintain.

How to choose a water flow sensor-relay

Before purchasing the unit, you must carefully read technical characteristics, scope of application, capabilities of the device.

What to pay attention to:

- wide operating temperature range;

- amplitude of pressure level indicators;

- diameter of threads and mounting holes;

- protection class;

- application features;

- manufacturing material.

The easiest way to handle is a metal water flow switch; the price of units starts from $25-30, but it all depends on the type of device. The metal body and working elements are characterized by high strength, which means that the device will withstand long-term pressure loads from the liquid flow.

Important! The pressure indicator is selected according to the power of the pumping system - the characteristic affects the parameters of the fluid flow passing through the pipeline system.

Particularly practical are devices with two springs, one of which controls the operation of the station at the upper, and the second at the lower pressure level. taken into account climatic conditions operation and recommended humidity level. Limit maximum permissible loads indicated in the protection class specifications.

The diameter of the thread sections and mounting holes is checked for subsequent installation of the device. If it perfectly matches the pipeline elements, joining will not cause any difficulties, and there will be no leaks during equipment operation.

Review of famous manufacturers and prices

Several models are considered the most famous and reliable price category 30-40$:

- Genyo Lowara Genyo 8A. Manufacturer – Poland. The main direction of the company is the production of electronic equipment for control systems. The relay is designed to work in water pipes household use and is characterized high quality, long service life. By monitoring the flow pressure in the pipes, the sensor starts pumping system with a water flow rate of 1.6 l/minute. The unit requires an electrical connection and consumes 2.4 kW/hour. Worker temperature regime+5..+60 C.

- Grundfos UPA 120. Manufacturer's plants are located in Romania and China. The device has small dimensions, is convenient to install and is indicated for individual water supply systems. That is, it can be used both in private buildings and apartments. The device starts up at a liquid flow rate of 1.5 l/minute, completely preventing the functionality of the system for Idling. Extreme indicator operating temperature+60 C.

The models have been tested and adapted to domestic operating conditions. Numerous reviews characterize metering sensors as durable and practical units at an affordable price.

Installation of a relay on a pump or station

If installation of the device is required, the work can be done independently, especially if you have to be away and there is no way to constantly monitor the operation of the pumping equipment.

When you do not need to install a relay:

- if water is pumped from a well with a large volume, that is, liquid reserves are not limited, and the pump power is minimal;

- It is possible to turn off the installation when the water level drops.

Equipment installation rules:

- It is important to monitor the membrane - the part must take a vertical position.

- Installation is carried out to the drain pipeline section using threaded couplings. There is a special slot for this.

- Before starting work, the threads are sealed with flax or other plumbing thread. Winding the thread towards the end clockwise will increase the reliability of fastening and fixation.

- Factory sensors are equipped with an arrow drawn on the body - this is the direction of flow, which must match during installation.

- When installing relays in water supply pipelines with dirt particles, cleaning filters are first installed. Mount them better nearby with sensor to extend the life of the device.

Testing of the installed device is carried out with connection to the power supply:

- the free ends of the contacts are connected to the wire core;

- grounding is mounted to the screw;

- the device is connected by connecting the device with a wire (watch the color of the corresponding wires);

- system functionality is checked.

Worth knowing! If the device is connected correctly, the pressure mark on the pressure gauge will begin to increase, and then the pump will turn off automatically as soon as the pressure gauge needle goes beyond the limit value.

Self-adjustment of the water movement sensor

The factory device is equipped with bolts, by tightening or loosening which you can increase/decrease the spring compression. Bolts will be required if you need to install the sensor at a certain pressure level at which the mechanism is triggered.

Algorithm of actions:

- drain the liquid from the system;

- wait until the pressure mark reaches zero;

- start the pumping unit;

- run the water back in the slowest mode;

- remember the flow pressure indicator when the pump relay is turned off;

- drain the liquid again, recording the indicators when the system starts operating.

Now you need to open the relay, use the bolt to adjust the compression level of the larger spring - this will trigger the device when the pump starts. The adjustment is made taking into account that strong compression will increase the degree of pressure, and weak compression will decrease it. Then the compression force of the smaller spring is adjusted - here the limit of the maximum pressure level is set, upon reaching which the relay will automatically turn off the pump.

As soon as the adjustment is completed, start the system, evaluate the results of the work when filling the pipeline and draining the flow. If adjustment changes are necessary, repeat the procedure. Checking functionality and adjusting operating parameters is an annual procedure that extends the life of the device.