What is a CP sheet in construction? Cement particle board - characteristics of the material, application in construction and finishing. Composition of the CBPB board

Read also

Cement particle board - high quality and safe material, which is actively used in modern construction.

Let’s talk about what it’s good for, what materials can be replaced with it, and most importantly, how to use it.

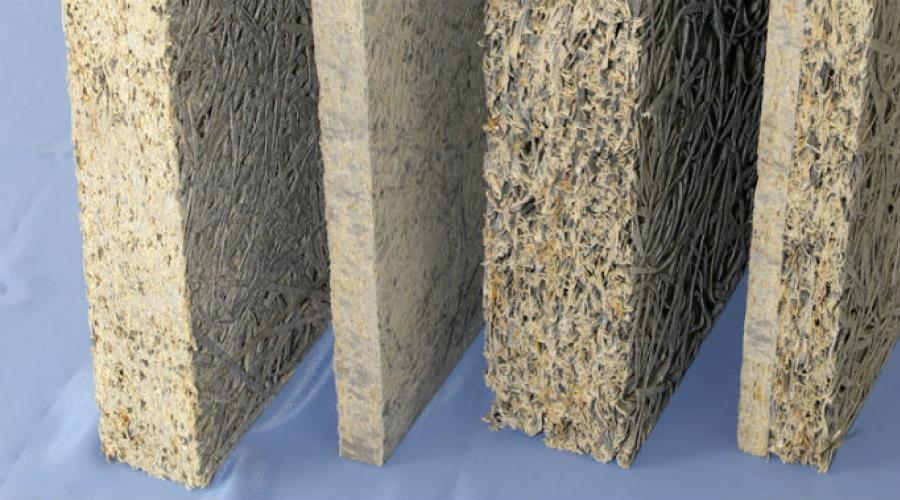

DSP is a building material, the peculiarity of which is its unique structure.

Cement particle boards consist of crushed pine needle shavings, which are small in thickness but impressive in length.

Length may vary. Feature- at the edges the chips are located along the slab, and inside - across.

This primarily affects the strength indicators.

Advantages of cement bonded particle boards

DSP can be used in areas high humidity, as well as in conditions characterized by a dry climate.

However, this is not the most important advantage of the material. Among other advantages it is worth highlighting:

- versatility. DSP is universal, both in conducting external repairs, and performing work on finishing the premises inside the house;

- high thermal insulation rates. If we, in which it is not planned to carry out heating, in the spring and autumn period the house will remain warm;

- cement bonded particle boards are easy to install;

- does not require complex processing, is sold ready-made (thanks to this, there is no need to maintain proportions or add impurities, thereby increasing your own chances of error and damage to materials);

- Bacteria do not multiply in the DSP. The environment that is created in the pores of the material, although safe for humans, is unfavorable for microorganisms;

- can be finished in any way, using any materials (painted, pasted over, plastered, and so on);

- lack of flammability. This can be achieved due to the fact that the CBPB contains cement;

- climate and temperature regime do not affect the structure of materials;

- DSP is not interesting for pests;

- does not contain formaldehyde and other toxic substances that continuously have a negative impact.

As a rule, DSPs are sold in certain sizes. There are 7 size options in total, which differ in length, width and thickness (and, of course, weight, respectively).

Where are cement bonded particle boards used?

How the slabs will be used directly affects the material. It is important to understand that there are two types of DSP: rough and smooth.

They can be used:

- for flooring;

- creating a warm floor;

- like partitions;

- DSP can be used as permanent formwork;

- sheathe frame house;

- room decoration.

A little about smooth... This type of slab is great for interior decoration. It is comfortable, easy to install, covers almost any type of finish for interior design.

If we're talking about about gluing wallpaper, it’s easy to prepare a DSP for this. In addition, wallpaper adheres well to slabs.

Similarly, DSP is used to create. The floor will be smooth, warm, reliable. If you cover both the walls and the floor with slabs, you can get an almost flat room.

By the way, the use of this material is also typical for the bathroom, since smooth slabs are usually impregnated with a special substance that protects the coating from moisture. No matter how humid the air is, the slabs do not deform.

DSP board with rough surface used outside the rooms of the house.

With its help, you can decorate the walls, leveling them and finishing them to your taste. Plates are used to form roofing pie, formwork, when constructing structures with a obviously small load during use.

By the way, sandwich panels are also made from DSP. This material is suitable for creating paths and paths, which, again, will not withstand heavy loads.

Cement particle boards are also suitable for creating furniture, large warehouse structures, and erecting fences.

Partitions made of cement-bonded particle boards

DSP can be used to create partitions. What is the advantage of these boards compared to the so popular drywall?

The latter is not resistant to moisture, and does not retain heat, but transmits sound perfectly, which can be called quite negative point.

In combination with DSP mineral wool or fiberglass can increase sound insulation several times.

It lends itself very well to cutting, which is a plus in areas where pipes and wiring pass through.

Finishing the premises with cement bonded particle boards

Along with the wide choice of applications for the slab, one can note the particular popularity of using it indoors.

Among slab and sheet materials, used for finishing and constructing partitions and various design elements, one cannot ignore cement-bonded particle board or DSP. Of course, in terms of popularity it is inferior to drywall, but, as practice shows, it is also suitable modern world there is a place. Most often, the DSP board is used by builders as formwork. It is smooth, with good strength, plus - with its help, it is much faster to assemble formwork than from boards.

Many may doubt that the use of DSP is advisable for the construction of formwork. After all, it can be replaced, for example, by metal or plywood, which are also used. This is probably true, but a slab with a thickness of 24-26 mm can withstand quite serious loads. In addition, if you install permanent formwork using cement-bonded bonding material, then, in fact, you will get a finished foundation or other structural element building. And this is a big plus in many situations.

In addition, it is necessary to take into account the conditions under which the room being finished will be used. For example, if this is a gym, then there can be no talk of any drywall. He just can't withstand the ball's impact. And the DSP boards will hold up. They can be used for strapping and sheathing frame houses. Today you cannot find better material for this value. Another advantage is the ability not only to paint the cement-bonded particle material, but also to use it as finishing. Fortunately, manufacturers today offer huge assortment with registration under different materials, as shown in the photo above.

DSP production technology

From the name itself it becomes clear that the main components of this material are cement (65%) and wood shavings (24%). All this is mixed with water (8.5%), and various additives are added to the resulting mixture that improve specifications slabs (2.5%).

In the process of producing CBPB, two types of particle boards are used. They differ in size: small and medium. The plate itself has three-layer structure, so medium-sized chips are poured into the second layer, and small chips into the first and third. The production process itself takes place in the following sequence.

- The shavings are mixed with hydration additives.

- Cement grade M500 is added to the resulting mixture.

- Water is pouring in.

- The solution is thoroughly mixed until a homogeneous mass is obtained.

- The first layer of fine chips is poured into the mold.

- The second layer with medium-sized shavings.

- And the third layer.

- Pressing is in progress.

- After which the semi-finished material is heated to +90C for eight hours.

- Then, for 13-15 days, it is dried in natural conditions.

- After which, depending on the batch, it is either polished or simply stored.

Specifications

What is it durable material, understandable, because it includes cement component. But it is also moisture resistant due to the use of hydration components. Plus, DSP boards have excellent bearing capacity, which cannot be said about gypsum board or plywood. But a lot will depend on the parameters of the stove.

As for the width, it is standard - 1.2 m. But the thickness and length are dimensions that vary over a fairly wide range. As for the length, the manufacturer can cut it to any size if the order batch is large. But there are also standard values: 2.7; 3.0; 3.2 and 3.6 m.

As for thickness, there is a fairly decent range here too: from 8 to 40 mm. Accordingly, the weight of the product will increase with increasing thickness. For example, a slab 2.7 m long and 8 mm thick weighs 35 kg. With a thickness of 40 mm, the weight will increase to 176 kg.

With a DSP length of 3.2 m and a thickness of 8 mm, its weight will be 41 kg. With the same length and thickness of 24 mm, the weight will be 124 kg.

There are no rounded edges or chamfers in the design of the DSP boards. The edges are straight and cleanly cut, so there shouldn't be any problems with joining panels and fitting. They do not need to be treated with antiseptic compounds before finishing, because during the manufacturing process an antiseptic is added to the raw solution.

Other technical characteristics according to GOST:

- Withstands large subzero temperatures. In this case, the defrosting process can occur up to 50 times. After which the strength of the slabs decreases by only 10%.

- The error on the outer plane is 0.8 mm.

- The difference in the lengths of the diagonals can be 0.2%. This is practically no more than 5 mm for a length of 2.7 m.

- Thickness error (permissible) is no more than 0.8 mm. This is for unsanded material, for sanded material 0.3 mm.

- Water absorption is 16%, while per day at high humidity the slab should not increase in size by more than 2%.

- Withstand tensile loads - 0.4 MPa, bending loads 9-12 MPa, depending on the thickness of the product. The thicker it is, the less it can withstand bending loads.

Manufacturers today offer two types of cement-bonded particleboard material, which differ from each other in quality characteristics. These are TsSP-1 and TsSP-2. The first one is better.

There is an opinion that slabs of this type are inferior to plasterboard in many respects. You should not compare these two materials, they have different purposes and different areas applications. The examples described above confirm this. Of course, DSP has its drawbacks, which we’ll talk about.

- Compared to plasterboard, cement-bonded particle boards cost almost twice as much. But gypsum board cannot be used for exterior decoration, and it’s better not to sheathe a frame house with it.

- The weight of each slab can be terrifying, especially those with a thickness of more than 16 mm. You won't be able to work with them alone. Under them you will have to build a strong and reliable frame. And the foundation will have to be strengthened if they are used to cover a frame structure.

- In addition, the cement component gives the material increased strength, so it is difficult to process. Therefore, pruning must be carried out with a grinder or a hand-held circular saw, and it is not easy to use cutting tool, but diamond.

- The frame has already been mentioned, but it must be added that profiles for drywall are not suitable here, especially if we are talking about exterior decoration DSP slabs. A standard steel profile is required here.

- When cutting slabs, it releases a large number of dust, so this operation should only be performed outdoors.

Construction materials are constantly replenished with new products, or old ones are modified, becoming owners of higher technical and operational characteristics. In this article we will talk about one unique building material - cement bonded particle board. So, what is a DSP board: dimensions and price, characteristics and scope of application.

This material is made from two main components: shavings with the addition of liquid glass and other chemical additives. The photo below shows the proportions in which all the ingredients are used.

The production technology of CBPB is very similar to the production of boards. Here is the sequence of operations:

- The shavings are mixed with liquid glass and other chemical additives.

- Cement and water are added.

- The slabs are formed under a press pressure of 2−6 MPa.

- Heat treatment is carried out.

- The ends and sides of the slabs are treated with protective substances.

- For 14 days, the products are stored at a certain temperature and humidity up to completely dry and polymerization of binder components.

Attention! All factory-produced CBPB boards must comply with GOST 26816-86 and be certified.

Technical characteristics of CBPB boards and their application

The technical characteristics of this building material, like all others, determine its quality condition. Therefore, the table contains all the main parameters that affect the service life of the slab and its ability to withstand certain loads under operating conditions.

| Characteristic | Unit change | Index |

| Density | kg/m³ | 1100−1400 |

| Humidity | % | 9 |

| Water absorption | % in 24 hours | 16 |

| Swelling by thickness | % in 24 hours | 2 |

| Flexural strength (not less): thickness: | MPa | |

| 10,12 and 16 | 12 | |

| 24 | 10 | |

| 36 | 9 | |

| Tensile strength | MPa | 0,4 |

| Thermal conductivity | W/m K | 0,26 |

| dB | 46 | |

| Flammability class | G1 (low-flammability) | |

| Life time | years | 50 |

The ratio of the dimensions of the CBPB sheets: length, width and thickness with the weight of the slabs and their price

Now let's move on to the analysis of dimensional indicators. DSP is available in standard sizes:

- 2700×1250 mm;

- 3000×1250 mm;

- 3200×1250 mm.

Depending on the thickness of the panel, the volume of the material and its weight change. Both indicators are important to consider when transporting and calculating the load on bearing structures buildings in which CBPB boards will be used. Let's consider how the two indicators change depending on the thickness. The table will indicate panels with dimensions of 3000x1250 mm.

| Thickness, mm | Weight, kg | Volume of CBPB board, m³ |

| 8 | 41,6 | 0,032 |

| 10 | 52 | 0,04 |

| 12 | 62,4 | 0,048 |

| 16 | 83,2 | 0,064 |

| 20 | 104 | 0,08 |

| 24 | 124,8 | 0,096 |

| 26 | 142,2 | 0,104 |

At what prices can you buy cement bonded particle board?

Depending on the dimensional parameters, the price of the products also changes.

csp plate

It should be noted that CBPB boards of the same thickness differ slightly in price, for example, 16 mm. The difference is only 50 rubles. But if the volume of material used is large, then the difference will be considerable.

Attention! Dimensional parameters: length and width when ordering by individual projects can be adjusted during the production process to the required parameters. The thickness remains unchanged within the limits established by GOST.

Where are CBPB boards used?

The scope of application of cement bonded particle boards is quite wide:

- : regular and ventilated;

- : floor, ceiling, walls;

- construction;

- as permanent formwork for pouring various building structures;

- during construction.

Advantages and disadvantages

Let's start with positive aspects material:

Now the disadvantages:

- The weight of the DSP boards is decent; even a small sheet of 10 mm thickness weighs more than 50 kg. It is beyond the power of one person to lift it and install it where required. And lifting material to the upper floors will require the use of lifting equipment, which increases the cost of the work performed.

- If DSP panels are used outdoors, their service life is reduced to 15 years.

Processing rules - what you can use to saw and drill CBPB boards

Whatever one may say, CSP is a concrete stone filled with shavings ( wood filler). Therefore, when the question is raised about how to process the material of this type, cannot be mentioned hand tool. Cutting and drilling can only be carried out with electric tools.

So, we considered the topic of CBPB boards. This is actually an interesting building material, which has recently been gaining popularity, especially among residents northern regions. If you have any questions about installation technology, prices and types, we are ready to answer them. Write in the comments, and our editors will definitely answer.

We will send the material to you by e-mail

The consumer market focused on construction and renovation work DSP board, the dimensions and prices of which allow it to be used for various purposes. We invite you to evaluate the advantages of a relatively new building material, study its technical characteristics and size range. You will learn about the basic rules DSP applications during floor installation, as formwork or a basic element in production. Features of installation using DSP will be considered, and it will also be proposed short review main producers of this material.

Facades finished with DSP acquire a stylish modern look

DSP is a cement-bonded particle board. On English language sounds like “cement bonded particle board”. Refers to a variety of sheet composite material intended for use in the construction industry.

Characteristics of CBPB boards: sheet dimensions and price, thickness, weight

Thanks to the variety of technical indicators that meet modern requirements, cement-bonded particle boards seriously compete with the common ones, flat slate and other sheet materials.

DSP board: technical characteristics, application

The main document that regulates the characteristics and use of CBPB boards is GOST 26816-2016. According to its provisions, two brands are distinguished - TsSP-1 and TsSP-2. They have some differences in the values of technical parameters.

Table 1. Technical characteristics of the DSP

| No. | Characteristics | Units | Indicators |

|---|---|---|---|

| 1 | Density | kg/m3 | 1100−1400 |

| 2 | Flexural modulus | MPa | |

| TsSP-1 | At least 4,500 | ||

| TsSP-2 | At least 4,000 | ||

| 3 | Bending strength | MPa | |

| TsSP-1 | 9−12 | ||

| TsSP-2 | 7-9 | ||

| 4 | Tensile strength | MPa | |

| TsSP-1 | Not less than 0.5 | ||

| TsSP-2 | Not less than 0.35 | ||

| 5 | Impact strength | J/m2 | Not less than 1,800 |

| 6 | Thickness swelling due to temperature and humidity influences, measured after 20 cycles. | % | No more than 5 |

| 7 | Reduction in flexural strength due to temperature and humidity influences, measured after 20 cycles. | % | No more than 30 |

| 8 | Swelling, measured by thickness, after 24 hours in water. | % | No more than 1.5 |

| 9 | Water absorption per day | % | No more than 16 |

| 10 | Hardness | MPa | 45-65 |

| 11 | Thermal conductivity | W/(m×˚C) | 0,26 |

| 12 | Specific heat | kJ/(kg×˚C) | 1,15 |

| 13 | Soundproofing ability | dB | 45 |

| 14 | Flammability group | - | G1 - slightly flammable |

| 15 | Flammability group | - | B1− difficult |

| Flammable | |||

| 16 | Flame Spread Index | - | 0 – no propagation occurs |

| 17 | Fire resistance limit | min | 50 |

| 18 | Smoke generation group | - | D - toxic substances are not released |

| 19 | Resistance exhibited when removing screws from a slab, in specific terms | N/m | 4-7 |

| 20 | Humidity | % | 6−12 |

| 21 | Frost resistance without damage, determined by the alternation of thawing and freezing | The number of cycles | 50 |

| 22 | Biostability class | - | 4 |

| 23 | Surface roughness | µm | |

| ground slabs | No more than 80 | ||

| unpolished | No more than 320 | ||

| 24 | Operating duration (dry conditions) | years | 50 |

The scope of application of cement bonded particle boards is quite extensive and includes several areas:

Weight of CBPB boards

Weight is most often assessed building materials, if you have to build a low-rise building on your own. This indicator has direct proportional dependence with the thickness and dimensions of the material.

If we consider a cement particle board with a length of 2700 mm and a width of 1250 mm, then the weight indicators depending on the thickness will have the following values.

With a length of 3200 mm and a width of 1250 mm, the weights will be as follows.

Note! Analyzing the indicators, it can be noted that with a thickness of 36 mm, the slabs become 4.5 times heavier than their eight-millimeter counterparts. Even 10 mm DSP has a fairly impressive weight, so it will be difficult for one person to work with such material.

Advantages and disadvantages of cement bonded particle boards

The popularity of DSP is based on a wide list of advantages of this material compared to analogues:

- Fire safety. Finishing made of cement-bonded particle boards does not support combustion. If a strong fire occurs nearby, they do not emit dangerous toxic elements.

- Multifunctionality. Possibility of using the material in different roles: partitions, finishing, creating a rough foundation.

- Biostability. Cement particle boards are not colonized by fungi. They are resistant to rodents and various bugs.

- Frost resistance. This characteristic becomes especially important when using the material in regions with severe winters.

- Reliability. Even in conditions of frequent temperature fluctuations of the slab long time are not subject to deformation.

- Noise insulation. The structure of the slabs allows you to protect living spaces from external sound influences.

- Moisture resistance. Even when used for finishing external facades, the material withstands atmospheric conditions well.

- Quick installation. If a private house is being built, then finishing it using DSP is carried out at a rapid pace, thanks to large area sheets.

Among the disadvantages is the high weight of the material, which makes it difficult to use on upper floors without special equipment. Another inconvenient factor is the abundant formation of dust during the process of sawing slabs.

What and how are CBPB boards made from?

The composition of cement bonded particle boards includes the following components:

- Portland cement −65%;

- wood shavings −24%;

- water −8.5%;

- additional impurities - 2.5%.

Aluminum sulfate is used as a supplement, liquid glass. It is necessary to pay attention to the product passport, which reflects these indicators. Also included is a certificate of certification and a quality passport.

The technological process consists of several stages:

- The chip component is mixed with hydration additives.

- Water and cement fraction are added.

- A slab is forming required sizes under pressure.

- It should be heated to 90 degrees and hardened under such conditions for eight hours.

The slabs are then aged to achieve their final hardness levels under natural conditions for two weeks. The last stage is grinding if it is provided for in the technological map.

Slab manufacturers have special equipment, conveyor lines, comply with GOST standards, carry out necessary control quality.

Main sheet sizes, prices and where to buy cement bonded particle board

GOST 26816-2016 regulates two standards for the length of CBPB: 3200 and 3600 mm. And also two width options: 1200 and 1250 mm. Among the assortment different manufacturers the most popular products are 2700 cm long with standard width. Thickness values starting from 8 mm are graded in 2 mm increments. GOST reflects the possibility, if necessary, to order the manufacturer to produce slabs with other sizes.

The price of building materials also depends on the main dimensions. Below is an overview of the cost of the most popular types of cement bonded particle boards.

With a length of 2700 cm and a width of 1250 cm, prices vary within the following limits depending on the thickness.

| Thickness, mm | 8 | 10 | 12 | 16 | 20 | 22 | 24 | 36 |

|---|---|---|---|---|---|---|---|---|

| price, rub. | 677− 703 | 816− 875 | 917− 987 | 1154− 1192 | 1421− 1440 | 1500− 1548 | 1560− 1580 | 1 605− 1700 |

The price for dimensions 3200x1250 mm is the following average values.

| Thickness, mm | 8 | 10 | 12 | 16 | 20 | 22 | 24 | 36 |

|---|---|---|---|---|---|---|---|---|

| price, rub. | 714− 738 | 838− 898 | 946− 1019 | 1166− 1178 | 1419− 1576 | 1608− 1634 | 2173− 2185 | 2193− 2198 |

Price for dimensions 3600x1200 mm.

| Thickness, mm | 8 | 10 | 12 | 16 | 20 | 22 | 24 | 36 |

|---|---|---|---|---|---|---|---|---|

| price, rub. | 755− 950 | 970− 1200 | 1150− 1250 | 1360− 1550 | 1365− 1600 | 1850− 2005 | 2350− 2650 | 2700− 2885 |

Based on average prices, you can calculate how much it will cost modern material necessary for carrying out the planned work. For example, the price of a 16 mm DSP board with a length of 3600 mm is 1500 rubles. To cover the facade, 35 slabs will be required. Therefore, you will have to spend 52,500 rubles on the purchase.

You can purchase cement particle board in stores specializing in the sale of building and finishing materials. Here you can get the necessary advice on choosing the right variety.

You can find many offers in online stores both from manufacturers and from representatives of companies producing this modern and popular material.

Handling rules - how to cut CBPB

Cement particle boards, which are superior in hardness, cause virtually no difficulties during processing. They drill and mill well. For example, to drill a hole, use screw drills, and the work is performed at high speed.

If it is necessary to cut CBPB, then at home they use different instruments. Be sure to wear safety glasses and a mask over your mouth and nose, as large amounts of dust are generated.

Expert's point of view

Dmitry Kholodok

Technical director of the repair and construction company "ILASSTROY"

Ask a Question"Can be used electric jigsaw, but you should select special files designed for cement. They are equipped with carbide tips.”

To reduce the amount of dust formation, it is recommended to irrigate the cutting area with water from time to time. You can remove dust immediately using a vacuum cleaner, which should be held by an assistant.For slabs thicker than 12 cm, it is advisable to use an electric disk tool.

Advice! Select discs that are designed for working on concrete, stone or brick. They are diamond coated. Preference is given circular saw, since when working with it, less dust is generated than from an angle grinder.

Scope of application of DSP in construction and repair

Considering the characteristics of DSP, the scope of its application is quite extensive. When using, recommendations for selecting material thickness are taken into account.

DSP façade finishing

Facades finished with cement-bonded particle boards become presentable appearance, the coating made of cement-bonded particleboard imitating brick looks especially attractive.

This building material does not require additional coating, reliably protecting the building from external influences. You can purchase cladding with the texture of stone, marble and other types of crumbs.

If the goal is insulation, then a material with a thickness of 8–16 mm is used, under which the insulation is first laid. Then the sheathing is formed and the facing slabs are fixed. A ventilation gap is provided.

Application of DSP boards for flooring

DSP is becoming a popular material when laying floors. If you plan to directly lay the DSP on the floor along the joists, the thickness of the material is selected in the range from 20 to 26 mm. This provides good strength with an average lag pitch of 0.6 meters.

The result is a smooth rough base, ready for finishing. Self-tapping screws are used as fasteners.

Often, 12mm DSPs are used to level a floor structure whose structure is multilayer. In such a situation, logs, waterproofing, and plank covering are laid on the subfloor. The next layer is DSP, providing not only a flat floor surface, but also sound insulation.

If you use DSP with decorative front layer, then you can immediately get a clean floor without the need to lay other materials on top. This material is also used for installation. When constructing utility and storage buildings, laying slabs with a thickness of 24-26 mm is allowed directly on leveled bulk soil.

Production of SIP panels from DSP

An improved version of the new generation of building materials are SIP panels, the basis of the design is DSP.IN production process a sandwich is formed, for which insulation is placed between two cement-bonded particle boards, fixed under high pressure using glue.

The resulting structure is highly durable and does not require additional operations to insulate the building after installation. Using quality species heat-insulating layers SIP panels are environmentally safe and resistant to fire.

Article

DSP board (cement particle board)- popular construction and finishing material, consisting of wood chips, Portland cement, water and special additives that provide the necessary performance characteristics.

The slabs are made by pressing. The result is durable sheets with smooth surfaces and ends, which allows you to significantly save time during their installation. This non-flammable material, therefore it is recommended for widespread use in construction.

DSP is used:

- as cladding of columns, internal and external cladding walls, entrance door trim

- for the construction of moisture-resistant partitions and wall cladding in wet rooms

- as a front covering for floors, ceilings, window sills, creating a base for roofing

- as permanent formwork for building foundations

Technical characteristics of cement bonded particle board

DSP, whose technical characteristics are among the best among wood-based panel materials, is wide application in construction, agriculture and other areas of our lives. In this table you can see the main technical characteristics of cement bonded particle boards.

| Index | Unit | Meaning |

|---|---|---|

| Modulus of elasticity in bending, not less | MPa | 3000-3500 |

| Impact strength, not less | J/m² | 1800 |

| Density | kg/m³ | 1100-1400 |

| Tensile strength perpendicular to the slab layer, not less | MPa | 0,35-0,4 |

| Humidity | % | 9±3 |

| Water absorption in 24 hours, no more | % | 16 |

| Reduction in bending strength (after 20 cycles of temperature and humidity influences), no more | % | 30 |

| Thermal conductivity (m-°C) | W | 0,26 |

| Flame Spread Index | 0 (flame does not spread over the surface) | |

| Smoke generation group | D (does not emit toxic gases and vapors) | |

| Warranty period of operation in building structures | years | 50 |

| Flexural strength | MPa | 7-12 |

| Hardness | MPa | 45-65 |

| Specific resistance to pulling screws out of the formation | N/m² | 7 |

| Frost resistance cycles | 50 | |

| Swelling in thickness in 24 hours, no more | % | 2 |

| Swelling in thickness (after 20 cycles of temperature and humidity influences), no more | % | 5 |

| Specific heat | kJ (kg-°C) | 1,15 |

| Fire resistance limit | min | 50 |

| Biostability class | 4 | |

| Flammability group | G-1 (hard to burn) |

Advantages of DSP

- Environmental friendliness. Cement particle boards do not emit into the atmosphere toxic substances and do not contain components hazardous to human health.

- Fire safety. Does not spread combustion and does not ignite within 40-50 minutes of exposure to fire.

- Compatible with other materials. The DSP sheet has smooth surface, so you can lay tiles on top of it, glue wallpaper, and paint without preliminary leveling.

- Water resistance. The material has low water absorption and retains its original dimensions after drying.

- Biostability. Not susceptible to mold and mildew, does not attract insects and rodents.

- Durability. The material has high mechanical strength and retains performance characteristics for at least 50 years.

Dimensions of DSP

Look at the sizes and thicknesses of the CBPB sheets:

| Manufacturer Tamaksky plant | Manufacturer Kostroma plant | ||

|---|---|---|---|

| 2700x1250x8 mm | 3200x1250x8 mm | 3200x1200x8 mm | 2700x1200x8 mm |

| 2700x1250x10 mm | 3200x1250x10 mm | 3200x1200x10 mm | 2700x1200x10 mm |

| 2700x1250x12 mm | 3200x1250x12 mm | 3200x1200x12 mm | 2700x1200x12 mm |

| 2700x1250x16 mm | 3200x1250x16 mm | 3200x1200x16 mm | 2700x1200x16 mm |

| 2700x1250x18 mm | 3200x1250x18 mm | 3200x1200x18 mm | 2700x1200x18 mm |

| 2700x1250x20 mm | 3200x1250x20 mm | 3200x1200x20 mm | 2700x1200x20 mm |

| 2700x1250x24 mm | 3200x1250x24 mm | 3200x1200x24 mm | 2700x1200x24 mm |

Where to buy cement bonded particle boards

You can buy a DSP board on our warehouse complexes in Moscow and Moscow region. You can order delivery of material with payment on the spot. It is possible to form prefabricated machines with