What is a jack? Which jack to choose, what to pay attention to? Tips and tricks. Automotive rack and pinion jack

Read also

The hydraulic jack has a device and operating principle based on the physical properties of liquids that retain their volume during the compression process.

A hydraulic jack is a portable lifting device designed for heavy objects.

Purpose of a hydraulic jack

A hydraulic jack is a stationary, portable or mobile lifting device designed for heavy objects. It is used when performing repair and construction work and as part of cranes, presses, and lifts.

Modern designs of hydraulic devices are used in the oil refining industry, facilities in the energy sector of industry, and in agriculture. The high level of performance and efficiency, ease of operation and maintenance allow the use of hydraulic jacks in the domestic sphere.

This type of equipment can easily function in both horizontal and vertical positions, which has found its application on sites for installation and construction work. The unit is used for tensioning reinforcement structures made of stressed concrete.

Hydraulic lifting device design

The unit is designed as follows:

- frame;

- working fluid;

- working piston.

The design of the device can have an elongated or short body, for the manufacture of which hardened special steel is used. The body of the device is assigned to perform several functions. It is a guide cylinder for the working piston and serves as a reservoir for storing working fluid.

A screw with a lifting heel is capable of being screwed into the plunger using a special thread. By unscrewing it, you can change the maximum lifting height of the jack heel. Hydraulic devices are equipped with working pumps that have a manual, foot or air drive. The design provides for the installation of safety valves and some structural elements that ensure long-term and trouble-free operation of the lift.

The hydraulic pump and cylinder with piston are designed in such a way that they provide extension and lifting of the special platform. After the rod has been extended, the return to the initial position is carried out using a bypass valve.

There are several different modifications of hydraulic lifting units, which have their own areas of application.

The most common are:

- bottle type devices;

- rolling-type devices;

- hydraulic jacks of hybrid design;

- hook-type units;

- diamond aggregates.

Various designs of hydraulic jacks have their own characteristics in the device, which are determined by the scope of application of the device.

Each type of hydraulic jack is designed differently, however, the operating principle is the same for all.

The operating principle of a hydraulic jack is based on the use in the design of the apparatus of communicating vessels with a working fluid, the role of which is played by a special oil. Before use, the device must be placed on a flat, hard surface and the bypass valve must be closed. After installing and preparing the unit, you can use it for work.

The rod and heel are lifted using a pump that forces working fluid into a special cylinder.

Due to the property of the liquid to resist compression when the pressure increases, the piston moves in the working cylinder. This leads to the movement of the rod with the lifting heel. The latter is released by opening the bypass valve counterclockwise.

Pumping of working oil is carried out by a drive pump and a lever mounted on it. Oil moves from the pump to the working cylinder through a special valve.

The return of liquid during operation of the device is prevented by two valves: discharge and suction.

To install the lift in its original position, a special valve is provided in its design, when opened, the working fluid flows from the cylinder into the pump of the unit.

The presence of a screw in the jack device under the working heel allows you to expand the possibilities of using the device.

To carry out lifting, a special heel is made of high-strength steel. The hydraulic jack force is adjusted using a built-in pressure gauge.

Advantages and disadvantages of hydraulic jacks

The physical properties of the liquid allow for smooth lifting and lowering of the load and fixing it at a certain height. Hydraulic jacks provide a high efficiency rate, which reaches 80%. The load capacity of the unit is due to the presence of a large gear ratio between the cross-sectional parameters of the pump and working cylinder and plunger.

It is necessary to regularly wash the hydraulic jack, as well as change the oil and pump it.

Hydraulic lifts have a number of disadvantages. First of all, it should be noted that any model of this equipment has a certain starting height for lifting the load, below which the device cannot be operated. The disadvantage of this equipment is also the inability to accurately adjust the lowering height. In order to ensure uninterrupted operation of the device, it is recommended to constantly monitor the cleanliness, quality and level of oil in the jack reservoir. The normal operation of the device is ensured by the tightness of the valves and seals used in the design of the unit. The device must be transported and stored exclusively in a vertical position; if this requirement is violated, the working fluid may leak out of the device’s reservoir.

One of the disadvantages is the slowness of the units in operation. The disadvantages also include the weight of the device, its large size and high cost. In addition, single-plunger devices have a small stroke of the working rod, which is another disadvantage.

Possible malfunctions in the operation of the hydraulic jack

In any case, hydraulic jacks require care and maintenance, which consists of adding oil to the working reservoir of the unit. In addition, after a certain period of operation it is necessary to wash the device, change the oil and pump it. Oil from the working reservoir can leak through the oil seals and various seals used in the design of the device. In addition to leakage, during operation of the device, malfunctions such as jamming when lifting and the impossibility of lowering the rod may occur.

To eliminate oil leakage during operation of the device, seals and seals are replaced. For this purpose, specially designed repair kits are used. During the repair process, the unit is disassembled, seals are replaced, the hydraulic jack is assembled, after which it is filled with working fluid and pumped.

To eliminate jamming, the device is disassembled and its components are inspected for corrosion and contamination. If the first is detected, special treatment is carried out and the dirt is washed away.

What is a jack, types of jacks, jack design, operating principle of a hydraulic jack

What is a jack? This is a stationary, portable or mobile lifting mechanism for lifting and fixing heavy objects at a given height. The jack can be used as an independent device when performing repair or construction work, or as part of more complex mechanisms (cranes, lifts, presses, etc.)

As a rule, many people associate a jack with changing car wheels. In fact, it is used much more widely. The jack can perform both complex operations, such as moving bridge spans, and easier ones: lifting and holding the car body during repair work. Also, with the help of a modern jack, you can tension wires on high voltage lines, compress a powerful spring, push a water pipe through the ground, destroy an old ceiling in a building, and much more. Without a jack, it is impossible to lift and move large blocks or individual parts of mounted structures, components or equipment parts. Unlike other similar devices (for example, winches), it is more compact, easy to maintain, and reliable in operation. Another difference is that during operation the jack is always located directly under the load.

Based on the type of drive, jacks are divided into manual and electric. According to the operating principle and design features, jacks are divided into rack and pinion, screw, hydraulic (including special) and pneumatic. The lifting capacity of some jacks reaches hundreds of tons, the lifting height varies from a few centimeters to several meters.

Simple and convenient rack and pinion jacks :

The main part of a rack jack is a load-carrying steel rack with a support cup for the load. An important feature of the rack jack is the low location of the lifting platform. The lower end of the rack (foot) has a right angle for lifting loads with a low supporting surface. The load lifted on the rail is held by locking devices.

Based on the type of transmission mechanism, rack and pinion jacks are divided into lever and gear. In the first case, the rack is pulled out by a swinging drive lever, in the second - by a gear rotated by a drive handle. Jacks with a lifting capacity of up to 6 tons have a single-stage transmission, from 6 to 15 tons have a two-stage transmission, and over 15 tons have a three-stage transmission.

Jacks work in both vertical and horizontal positions. These devices are simple and easy to maintain, and their maintainability is high. Their advantages also include a large working stroke and lifting height, compactness, smooth running, and high efficiency (up to 0.85).

Reliable and stable screw jacks:

The main part of a screw jack is a screw with a hinged load-bearing cup, driven by a handle. The role of load-bearing elements is performed by the steel housing and the screw. Depending on the direction of rotation of the handle, the screw raises or lowers the folding arm. The load is held in the desired position by braking the screw, which ensures safe operation. To move the load horizontally, a jack on a skid equipped with a screw is used. Loading capacity of screw jacks is up to 15 tons. The main advantages of screw jacks: significant stroke and lifting height, low weight, low price. In most cases, a screw jack is reliable in operation. This is due to the fact that the load is fixed by a trapezoidal thread and when it is lifted, the nut rotates idle. In addition, the advantages of these tools include strength and stability, as well as the fact that they can work without additional stands.

Powerful hydraulic jacks:

Hydraulic jacks, as the name suggests, they operate on liquid. Such jacks differ in design (single and double plunger) and type of drive (manual intermittent action or electric continuous action). The main load-bearing elements: housing, retractable piston (plunger) and working fluid (usually hydraulic oil). The housing is a guide cylinder for the piston and a reservoir for the working fluid. The force from the drive handle is transmitted through the lever to the injection pump. when moving upward, liquid from the reservoir is supplied to the cavity of the pump, and when pressed, it is pumped into the cavity of the working cylinder, moving the plunger. The reverse flow of liquid is prevented by the suction and discharge valves.

The advantages of hydraulic jacks include structural rigidity, stability, smooth running, braking accuracy, high load capacity, compactness, less force on the drive handle, high efficiency (0.75-0.8). The design of a hydraulic jack allows you to lift loads from a minimum height of almost foundations of the structure. This expands the scope of its application compared to a mechanical jack. The disadvantages include low speed, low lifting height in one working cycle, and complexity of the design (a hydraulic jack can only be transported and stored in a vertical position, otherwise the working fluid may leak out of the tank). Another difficulty is that it is impossible to accurately adjust the lowering height. In addition, these jacks can suffer significantly more serious failures than mechanical lifting devices.

The lifting capacity of hydraulic jacks ranges from 2 to 200 tons. There are many variations of the mentioned devices - these are classic bottle jacks (single-rod and telescopic), rolling jacks, and special jacks - diamond-shaped, two-level and hook-type. The fundamental difference between special hydraulic jacks and conventional ones is that they are designed for lifting heavy loads to a significant height, reaching several meters. Moreover, special-purpose jacks allow you to fix and hold loads at this height.

The bottle-type hydraulic single-rod jack is distinguished by its simplicity of design and ease of operation, which expands its scope of application and allows it to effectively perform work of any complexity.

A type of hydraulic jack is a rolling jack. A lever with a lifting foot extends from a low steel case on wheels using a plunger. As a rule, such a jack is equipped with a long drive handle, due to which the working force is reduced. But the rolling jack only works on flat and hard surfaces. In order for jacks, as well as other hydraulic tools, to serve for a long time and reliably, you must strictly follow the operating rules. It is precisely because of violation of instructions that the overwhelming number of breakdowns occur. In particular, you need to ensure that dirt and sand do not get into the working fluid, and also monitor the oil level in the tank.

Pneumatic jacks and glass jacks:

Pneumatic ones are indispensable in the case of a small gap between the support and the load, for small movements, for precise installation, and if there is work to be done on loose, uneven or swampy soil. Pneumatic jacks are actively used during repair, construction and installation work at any site. The pneumatic jack is a favorite tool of car enthusiasts. In terms of minimal physical costs, perhaps no other similar device can compare with it. The main disadvantage of pneumatic jacks is their high cost. It is influenced by the relative complexity of the design, mainly associated with sealing joints, and the expensive technology for manufacturing hermetic shells. To complete the picture, it’s probably worth talking about glass jacks, or in common parlance, suction cups. They are used for carrying and mounting glass, glazed tiles and plastic. The glass jack is a plastic body with a rubber sole. Depending on the number of suction cups, these devices are divided into one-, two- and three-section ones.

Which jack do you prefer?

When choosing, it is necessary to take into account the load capacity - the maximum force developed by the jack. Of no small importance is the height of the pick-up - the vertical distance from the supporting platform to the pick-up in its lower working position.

Other important characteristics: lifting height, working stroke. You need to pay attention to how much effort is required when lifting the load. It is necessary to take into account how stable the jack is, that is, how capable it is of maintaining its working position under the influence of various factors. Will it fall due to improper installation, uneven working surface, strong gust of wind, etc. Stability mainly depends on the area of the supporting platform and on the rigidity of its connection with other parts of the jack.

And finally, one more important point. One type of jack or another should be chosen depending on the type of work that needs to be done. In addition, this instrument, like any other, requires not only skill, but also careful handling.

Common characteristics of jacks:

Jack lifting capacity- characterizes the maximum possible weight of the load being lifted.

Pickup height is the minimum distance between the supporting surface (ground, floor) and the pickup (support point of the jack) in the lower working position, respectively, the lower edge of the load. In automotive terms, this is ground clearance.

Lifting height - the maximum distance from the supporting surface to the pick-up in the upper working position.

Working stroke - the distance between the lower and upper working position of the pick-up.

Dead weight - the weight of the jack in working condition.

For some types of jacks, the characteristic of the gear ratio is also relevant - for example, the ratio of the area of the plunger of a hydraulic pump to the area of the lifting plunger in hydraulic jacks. The force on the handle of a jack with manual pumping or the power of the motor of an electric pump depends on it.

Hydraulic jack device.

Operating principle of a hydraulic jack.

As the name suggests, the principle of operation of such jacks uses liquid, or more precisely, the principle of communicating vessels. The working fluid is usually used hydraulic oil. Let's look at the diagram:

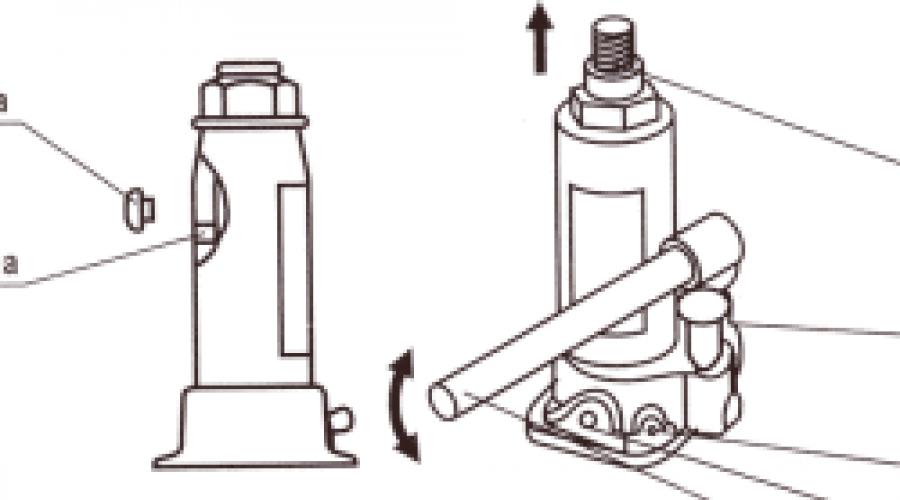

The illustration shows a typical design of a so-called hydraulic bottle jack. By pumping the pump manually or electrically, the user fills the bottom of the cylinder with oil and pushes the piston up. A characteristic and necessary part of such a jack is a bypass valve, which in turn consists of a suction and discharge valve. They allow you to create and maintain pressure in the working cylinder. The suction valve is located on the reservoir nozzle and prevents the liquid from returning to the reservoir when the pump plunger is lowered. The pressure one, respectively, is located on the cylinder pipe; it prevents hydraulic fluid from leaving the cylinder when the pump plunger is lifted. By opening the valve with a screw, the pressure can be released and the load can be lowered to the ground. Actually - a reliable and time-tested design.

Advantages.

An important feature of hydraulics is the incompressible working material, that is, liquid. This results in smooth lifting and lowering, fixation of the load at the required height and precise braking. In addition, hydraulic jacks have high efficiency, up to 80%, and significant lifting capacity, up to 100 tons or more, with a relatively low force on the pump plunger.

Flaws.

As is usually the case, the disadvantages stem from the advantages. Hydraulic jacks are relatively slow - one pump cycle corresponds to a small lifting height. Another disadvantage is the difficulty of storage and transportation. A vertical hydraulic jack can only be stored and transported in a vertical position, otherwise the working fluid may leave the volume allocated to it and randomly spread throughout the surrounding reality.

A jack is a mechanical device designed to lift loads resting on it. It is often used to lift cars and other vehicles when replacing wheels and brake pads. The device is also included in more complex mechanisms where it is necessary to create a compressive force. Jack-like structures are found in wood splitters, tire cutters and pipe benders.

How to choose a jack

When choosing a jack, there is not much difference in how the lifting force of the mechanism is provided. Design features only affect the comfort of using the device, as well as its dimensions, weight and reliability.

When choosing equipment, the first thing that matters is:

- Minimum pick-up height.

- Maximum lift height.

- Load capacity.

Such a characteristic as minimum pick-up height indicates the initial working height of the jack. For example, if the lifting height is 40 cm, then it is impossible to use the device to lift a car whose distance from the road surface to the bottom is 30 cm. The lower the minimum lifting height, the more universal the jack will be and will be suitable for a larger number of cars. It should be taken into account that the pick-up height is directly proportional to the lifting rate. Low jacks lift to a small height, which is often not enough, especially if you need to work with an SUV. In this case, the lifting mechanism has almost reached the last point and is just beginning to rest against the bottom of the car, as a result of which the wheels actually lift off the road by a few centimeters.

Maximum lift height is also an important indicator that you need to pay attention to when choosing a jack. This figure for most devices is in the range from 30 to 50 cm. This is more than enough to change a wheel in a car or create conditions for access to the bottom in the field. There are lifting mechanisms capable of lifting a load 1 m, but they are bulky and are practically not used in everyday life. The higher the rise, the more convenient it is to work with the car. It should be borne in mind that increasing the height negatively affects safety. If you work with a car at a large angle of inclination, it becomes unstable, so even if the technical capabilities of the lift allow for high lifting, they are rarely used to their fullest.

Load capacity the jack is also an important characteristic. Conventional household appliances, which are included in passenger cars and carried in the trunk with other field repair tools, are capable of lifting 2 tons. This is more than enough, since in fact only part of the weight of the car rests on the jack, since the mass is distributed between it and the wheels that touch the road surface when the car is tilted. Thus, even if the car weighs 2.5 tons, a jack of 2 tons will be enough. At the same time, it is strictly forbidden to use weak lifting mechanisms for heavy loads, the mass of which clearly exceeds their capabilities.

Types of compact jacks

There are several types of jacks that have different operating principles or combine several methods of lifting. The difference in this criterion is not so important from a practical point of view, but it affects the comfort of using the device.

By type, jacks are divided into the following types:

- Hydraulic bottle bottles.

- Hydraulic hook.

- Pneumatic.

- Rack and pinion.

- Screw.

Hydraulic bottle

Hydraulic type bottle jacks are the most common. They have a high lifting tonnage, good lifting speed, smooth running and fast lowering. Such devices, despite their modest dimensions, can cope with heavy loads. The principle of operation of the hydraulic mechanism is to create pressure with hydraulic fluid, which extends the working rod of the tool. The latter, resting against the load, continues to move, thereby lifting it to the required height.

These jacks got their name due to the fact that they have the shape of an ordinary bottle. Such devices are universal because they can be placed under the bottom of almost any car. When choosing a point of support for the jack, the main condition is to find a rigid surface that will not deform due to the fact that it will support the weight of the entire car. Manufacturers specifically provide reinforced places under cars for installing jacks.

To create sufficient hydraulic pressure to extend the rod and lift heavy objects, it is necessary to pump the oil in the jack using a small handle. It swings almost effortlessly, which is why this design is popular among motorists. To remove the oil pressure and lower the car back onto the wheels, you need to unscrew the special plug on the jack body using , or . As a result, the weight will be lowered in a matter of seconds.

Hydraulic hook

Hydraulic jacks of the hook type have an almost identical design to bottle devices. At the same time, they carry out lifting by preliminary hooking with a protruding L-shaped step, which is located on the side of the device body. Such a jack is placed under the low clicker of the equipment, which must be lifted by clinging to its threshold. In this case, the main part of the mechanism is located on the side of the car, so during installation there is no need to first try to push the device under the car. The range of toe load capacity is from 2.5 to 50 tons. Such devices can often be found in repair centers, since they are quite large and it is inconvenient to carry them in the trunk of a car, but there are exceptions.

Pneumatic

Pneumatic jacks work on a similar principle to hydraulic ones, except that they are pumped with air rather than oil. Thanks to this, their maintenance is accompanied by lower costs. To create compressed air pressure, the device has a high-pressure pump with a handle. In some devices, it is replaced with a regular one. The main feature of these jacks is their high operating speed. It is pneumatic jacks that are used at pit stops when replacing burnt out tires in Formula 1 racing.

The pneumatic jack is quite massive, but not too heavy. In order to ensure the lifting of the car, their design includes a folding bag that looks like accordion bellows. When air is pumped, it inflates and rises.

There are jacks that connect to a small car compressor designed to inflate the tires. Some devices are powered by exhaust gases generated by the engine during operation. They simply connect to the car's exhaust pipe. Exhaust gas driven jacks are only suitable for those vehicles whose engine does not stall when combustion products are pressed out under pressure.

The main disadvantage of pneumatic jacks is their unauthorized lowering. They are not designed to hold a load for long periods of time. In Formula 1 racing, where the wheels are changed in a matter of seconds, this is not a problem, but if you need to lift the car for several hours, then the pneumatic type is completely unsuitable. In this case, after lifting the car, you need to put stops under it. Immediately after this, the jack can be removed so that it does not interfere with work. If it is necessary to remove the car from the supports in the future, the lift is positioned, the bottom is raised a little higher and the supports are removed. They usually use bricks stacked on top of each other or a wooden log.

Rack type

Rack and pinion jacks are of the mechanical type. They have a one-way rack that supports the ratchet body. Using a folding grab bar, you can move the stop around the perimeter of the rail, gradually moving it up. Such devices often weigh more than 10 kg, so they are not popular. They can be seen in the configuration of old cars, such as the Soviet-style Volga. Such equipment has a high stroke height. Such devices carry out rapid lifting and are practically trouble-free. They require minimal maintenance, which consists only of periodic lubrication of the rack and the moving elements of the ratchet mechanism.

Screw type

Screw jacks are among the cheapest to manufacture. They are popular with certain car manufacturers, who offer them along with cars as standard. The principle of their operation is the presence of a threaded screw, which, when unscrewed, lifts the car. VAZ cars are equipped with such jacks. These devices have a low degree of security. Outwardly, they resemble an elongated rack, on which there is a platform protruding to the side, designed to hook a car. It is worth noting that it is a weak part of the structure and may burst when working in cold weather. Steel becomes brittle in the cold, so the seam between the main body and the platform fails. Even if the screw jack is made with high quality, it still has a small support area, which leads to insufficient stability of the vehicle being lifted.

It’s hard to imagine home renovations without it. Without this device, changing a wheel on the road is almost impossible. Using the device, even a child can lift the car; as you may have guessed, we are, of course, talking about a jack.

Before the advent of lifts, jacks were almost the only device that could be used to lift a large load and make repairs or replace a particular spare part. Despite the relative simplicity of its design, the jack does its job perfectly and is very popular among motorists. In this article I will try to talk about what types of jacks there are, as well as how to choose a good jack, by considering the advantages and disadvantages of each.

The choice is complicated by a large assortment; if there were two or three of them it would be much easier for the buyer, however, in any case, buyers benefit from the competition of manufacturers. The most important thing is to understand what kind of jack you need and distinguish a fake from the original. So, let's figure out what you need to pay attention to when choosing a jack.

Load capacity

The first is the most important parameter, this is, of course, carrying capacity. Its performance and, to a greater extent, its price depend on how much weight a jack can lift. Agree, it doesn’t matter who made it or what color the jack is if it can’t lift what you need. Each device has its own threshold, that is, the maximum weight that it can lift. Before how to buy a jack be sure to check the weight of your car, then add about 200-300 kg to this figure, this will be the carrying capacity that you need. The reserve is made so that if the car is loaded, your jack will not let you down, for example, there may be things in the trunk or any other cargo that will have to be unloaded if your jack cannot lift your car. A weak jack may not hold up and cause harm to you or your car, or at least fail, resulting in “wasted money”, and instead of a quick repair you will have to wait for help or call a tow truck.

Diamond jack

Owners of passenger cars will benefit from a mechanical-type diamond jack, with a small load capacity of 1.5-2 tons. This jack is designed to weigh approximately 1.3 tons, which is equal to the weight of an average sedan. Nobody forbids you to buy a more powerful jack, but it will be a waste of money, since you will never test the true potential of this jack in practice.

Rolling jack

For people who often repair cars or are seriously involved in car repairs, it will be very suitable rolling jack, with a carrying capacity of 3-8 tons. Here the stock will be relevant, since heavier vehicles may also come to you for “repair”.

Owners of heavy vehicles should take a closer look at jacks with a lifting capacity of 15-30 tons, maybe more. When purchasing, you should take into account the carrying capacity of the machine, since a puncture or breakdown may occur precisely at the moment when you are loaded. Example: the weight of a KamAZ car is 10 tons, its load capacity is 14 tons, I recommend buying a jack with a load capacity of at least 24-28 tons.

Lifting height

This parameter is responsible for the height to which the load is capable of lifting in relation to the surface on which it stands. Usually 30-50 cm is enough to replace a wheel or steering rack. If necessary, you can jack up the car higher by using various wooden or metal stands, or even buy a rack and pinion jack that can lift the car to a height of 1.50 meters above the ground. As a rule, it is necessary to raise it this high in exceptional cases, for example when the car is stuck in mud or other similar situations.

Rack jack

Pickup height

The pick-up height is essentially the height of the jack itself. The pick-up height is the height from which it can begin lifting. This point must be taken into account by owners of cars with low ground clearance. If you buy a jack that is too high or the pick-up height is higher than the point that needs to be lifted, then you simply will not be able to jack up the car, even if you have a very good jack for this. There are really options, you can, for example, make a dig or find a flat place with a hole in which you can install such a jack. If the ground clearance of your car is less than 15 cm, I recommend buying a rolling or screw jack, their lifting height is 6-9 cm.

Jack type (drive options)

Mechanical jack

The simplest budget type of jack is mechanical. They have the simplest design - a handle that rotates a threaded steel pin, as a result of which the weight is lifted. This jack is suitable for those who rarely use a jack and have impressive physical abilities. This option is unlikely to suit female drivers.

Hydraulic jack

Hydraulic jacks- lifting is carried out due to the oil pressure that is created in the cylinder when the handle is used. Hydraulic jacks are the most common among motorists, because they are very reliable, have excellent characteristics and are capable of lifting serious weight. And most importantly, you won’t need to make any effort to lift it; with “one finger” you can lift a multi-ton machine. Suitable for frequent use.

Pneumatic jacks(pneumatic jacks) - lift by pumping air into the working chamber. For their operation, a source of compressed air is required, for example: a pneumatic network, a gas cylinder or an exhaust pipe. The principle is simple: pressure arises in the chamber, which increases its size, resulting in lifting. No effort is required to work with such a device; the most important thing is to connect and install the jack correctly in the right place. Such jacks can be found in auto repair shops and service stations, as well as on production lines. Pneumatic jacks are also an integral part of off-road enthusiasts and all kinds of rallies; with their help, you can “get” your car out of any swamp and mud.

For general development and consolidation of the information received, I recommend watching the educational video on how to choose a jack. I will end here, I hope my advice will help you make a choice and buy a good jack. I would be grateful if you add the article to your social bookmarks. networks or share with friends. Those who wish to add to my story can do so using the comment form.

Since ancient times, people have been faced with the problems of lifting large loads to a height; for this, many people were usually involved, and bulky structures were erected, which were not always super-strength, and therefore often broke, causing casualties. A way out of the situation appeared with the invention of a machine such as a hydraulic jack, which is still widely used today. Such an installation, unlike winches, is more reliable and is capable of lifting large loads at lower costs.

Purpose of a hydraulic jack

Today it is impossible to imagine carrying out repair work on a car, be it suspension repair or changing a wheel, without the use of jacks - special mechanisms that are designed to lift a heavy load and fix it at the required height. The most effective are hydraulic jacks, where the working force is created using hydraulic oil and a piston.

The first mechanical jacks appeared in ancient times. And the idea of creating a hydraulic jack circuit specifically for a car arose unintentionally. Repairman Peter Lunati came across this idea in a hairdressing salon, being surprised at how easy it was for the hairdresser to fix the hydraulic chair at a certain height. In 1925, a complex platform lift with a hydraulic strut was made for a car.

Hydraulic jacks are distinguished by their lifting capacity, which ranges from one to several hundred tons, which allows them to be used in the repair of trucks and other heavy equipment.

Machine bodies or flooring, foundation slabs and columns are used as loads. Depending on the purpose of use, such equipment has different dimensions and designs.

A hydraulic jack is used to move, lift and secure loads. The device is used in the field of general mechanics and tire fitting work, and is also indispensable when preparing a car for a long trip to create balancing: the wheel is removed using a jack and balanced using special equipment.

Modern hydraulic jacks are widely used not only in service stations and car repair shops. They are successfully used in oil refineries, power plants and other industrial complexes. The highest level of performance and ease of operation have allowed this technology to be introduced into the domestic environment, which is why many owners have a hydraulic jack in their garage.

This equipment is capable of operating in horizontal and vertical planes, so it is widely used at the construction site and for tensioning reinforced concrete structures.

Hydraulic jack design

The main load-bearing elements of a hydraulic jack are the body, the working fluid, usually oil, and the retractable piston. The hydraulic jack has an elongated or short body that is made of hardened steel. The housing performs the following functions: it acts as a guide cylinder for the piston and serves as a reservoir for working oil.

The screw with the lifting heel is screwed into the plunger, turning the screw out, so if necessary, it is possible to increase the maximum lifting height. This type of jack is equipped with a hydraulic pump with manual, foot or air drive. The hydraulic jack is equipped with safety valves and other devices to ensure long-term trouble-free operation.

The lifting mechanism and retractable hydraulic cylinder, raised upward by a special platform, are located in the housing holes. The descent occurs by turning the T-shaped handle. The equipment has polyamide wheels, which provide the jack with maneuverability. The body of the extended shooting range is used mainly for working with buses and heavy vehicles.

Working principle of a hydraulic jack

Any hydraulic jack works on the principles of communicating vessels using liquid. Before work, you must place the jack on a flat, hard surface under the car and press the lever with the valve closed until the car rises to the required height. The vehicle is lowered by smoothly opening the device valve counterclockwise.

The working hydraulic oil is pumped by a drive pump using a lever. Liquid enters the cylinder through the valve and squeezes it out. The reverse flow of liquid will be prevented by valves - discharge and suction. To lower the jack back, you need to open the valve on the pump, then the oil will flow from the cylinder back into the pump.

The presence of threads on the body of the jack, which is protected by a dirt-proof casing, threads on the rod and threaded holes in the base, guarantees unlimited possibilities for the use and operation of hydraulic jacks for crimping, clamping and bending. A high-strength support, made of hardened steel and installed on the rod, can protect the hydraulic jack from damage. The corrugated surface of the support prevents loads from sliding. The force of hydraulic jacks is regulated by a built-in pressure gauge.

Advantages and disadvantages of hydraulic jacks

Hydraulic jacks are among the most unpretentious for all their power. An important feature of hydraulics is the incompressible working material. Hence the smoothness of lowering and lifting, fixing the load at the desired height and braking accuracy. Hydraulic jacks demonstrate a high level of efficiency - up to 80% and a significant load capacity - up to 200 tons with little effort due to the large gear ratio between the cross-sectional surfaces of the pump plunger and cylinder.

But hydraulic jacks have a much higher initial lifting height than mechanical models. Another difficulty is the impossibility of accurately adjusting the lowering height. To maintain the jack in working condition, it is necessary to constantly monitor the oil level and control the tightness of valves and seals. Such jacks can only be transported and stored in a vertical position, as otherwise the liquid may leak out of the tank.

The disadvantages of hydraulic jacks arise from their advantages. They are relatively slow - one cycle of pump operation corresponds to a not too high lift height. The disadvantages include the large weight and size, the high price of a hydraulic jack, as well as a small stroke for single-plunger models. In addition, these tools often experience more serious breakdowns and malfunctions than mechanical devices.

Classification of hydraulic jacks

There are several types of hydraulic jacks.

Bottle hydraulic jacks

The design of a bottle (vertical) hydraulic jack is the simplest. The scope of use of such jacks is quite wide due to the large range of lifted weights - from 2 to 100 tons. “Bottles” are used in trucks. In addition to the main advantages of a hydraulic jack, vertical models have several more - versatility of use, compactness and a large support area.

There are single-rod and double-rod bottle jacks. The hydraulic single-rod apparatus is distinguished by its simple design and ease of operation, which expands the scope of its use and allows it to perform work of any complexity: installation and dismantling in mechanical engineering, construction, repair of cars, wheels of railway cars, use as a power unit of a press, pipe bender, pipe cutter and similar tools .

A telescopic double-rod jack has a similar design to a bottle-type jack; the operating principle of a bottle-type hydraulic jack is based on the use of several working rods. The piston is located at the base of the telescopic jack. It can be used in horizontal and vertical positions. It is compact and fits most cars. Lifting occurs using a lifting lever driven by a hydraulic cylinder.

Rolling jacks

A rolling jack works on a similar principle to a bottle jack, but with the difference that the axis of the working cylinder is not located in the vertical axis, moreover, the piston is not directly aligned with the pick-up and the lifting lever is activated. This device is called a rolling device because it is a cart on wheels that can roll on a flat surface. When the lifting arm and lever are raised, the jack “rolls up” or moves under the load.

Such a jack is driven by the same swing of the lever as bottle models, and is lowered in the same way - by turning the valve screw. If it is necessary to lower the load down, it is necessary to place the tubular handle on the valve screw, after which the partition will fit into the groove of this screw. By rotating the handle around its axis, the user rotates the screw accordingly, relieving the pressure in the working cylinder and lowering the load to the required height.

Most often, a rolling jack can be found at a tire service station, because it is ideal for lifting one side of the car and is quite quick to operate and install. The disadvantages of this design follow from the name - a rolling jack needs a flat, hard surface, concrete or asphalt, to work. In addition, the significant size and weight make it difficult to transport the unit in a car.

Rolling jacks are classified by purpose, as in the photo of hydraulic jacks:

- For personal use by motorists, with a carrying capacity of up to 3 tons;

- For car services and tire shops, with a lifting capacity of up to 4 tons and with pre-lift pedals to instantly achieve the required pick-up height;

- For servicing heavy machines and special vehicles (forklifts), with a lifting capacity of up to 20 tons and with pre-lift pedals and a sliding crossbar, which is designed to lift one side of the machine.

Transmission rolling jacks are equipped with a special rotating frame. Here the smoothness and precision of hydraulic jacks is demonstrated in all its glory. The gearbox of a car that is being mounted or dismantled can be precisely fixed in a horizontal or vertical plane in the desired position.

Hydraulic hybrids

Two-level jacks are needed mainly in car repair shops, where they work with different cars. The features of this device include two lifting platforms. The drawing of a two-level hydraulic jack is generally a hybrid of a rolling jack and a bottle jack. To be more precise, a two-level jack is used at a height of 65 - 375 millimeters from the ground as a rolling jack and at a height of 375 - 687 millimeters as a telescopic one. When working with the lifting mechanism, use a hand lever and a foot pedal.

The pneumohydraulic jack combines hydraulics and pneumatics. It can be manufactured in a rolling solution and has a load capacity ranging from 2 to 80 tons. The initial pickup height is low. It is used exclusively as equipment for car service.

Hitch jacks

Low-lifting toe jacks are widely used wherever a low lifting height is needed: for installing and dismantling various equipment, for lifting rails on the railway, as well as in auto repair shops. It is this low pick-up height, which ranges from 15 millimeters, with the possibility of step-by-step adjustment that is very convenient when assembling mechanisms and acts as the hallmark of a hook jack. But this jack is based on a simple bottle-type device.

Diamond jacks

Hydraulic diamond jack is mainly required for lifting machines during repairs. It is characterized by high reliability when compared with its screw relative, and is practically not inferior to it in ease of use.

In a diamond jack, four levers act as load-bearing elements, which are connected by hinges. The operation of a hydraulic jack and lifting loads is based on changing the angles between the levers. The advantages of diamond jacks include their small dimensions, which provides convenient storage, transportation and, at the same time, a significant supporting surface and structural rigidity. Relatively low pick-up height.

Manufacturing of hydraulic press

When a car enthusiast independently services his entire vehicle fleet, one of the most necessary tools is a press. We suggest you make your own press from a hydraulic jack, which will become a reliable companion when performing a whole list of work. With its help, you can punch holes in different materials, press inserts and bushings, and press metalworking waste.

Assembling a hydraulic press is not that difficult. For this you will need a welding machine with the required number of welding electrodes, a hacksaw, an angle grinder with a metal disc, a thick-walled steel profile to construct the press. The functions of the power unit, which exerts the required operating pressure, are performed by a hydraulic jack.

The first unit of the hydraulic press is the support platform for the jack. Since the resulting pressure will be proportional to that applied to the base and upper working units, the strength of the base should be maximum. This can be achieved by making several stiffening ribs on the base. To make the base, take a steel square or rectangular profile that has a size of 40 by 50 or 50 by 50 millimeters and cut 4 parts about 250-300 millimeters long using the above tools.

After this, it is necessary to lay these parts with the side walls facing each other and weld the joining seams at the top and bottom to increase the rigidity of the base of the press. To ensure greater stability of the hydraulic jack, weld a steel plate to the resulting structure, the sheet of which has a thickness of 8 -12 millimeters and a size of 250 by 200 millimeters.

The next stage in the manufacture of a homemade press from a jack is the production of a stop and racks. To do this, you need to saw off 2 parts from a profiled thick-walled rectangular or square pipe of the required length. To calculate it, you need to clarify the maximum stroke of the rod using the instructions supplied with the jack and add the height of the hydraulic jack itself and the support platform to the resulting size.

Make the stop from the same material as the racks. The length of this part must be equal to the width of the support platform in order to maintain the overall geometry of the structure. Connect the stop and the resulting posts with a weld and weld the U-shaped structure to the base.

When performing such assembly operations, it is recommended to use a simple device that ensures the perpendicularity of the parts to be joined. On a steel sheet that is at least 10 millimeters thick, two pieces of steel angle 40 by 40 millimeters should be welded at an angle of 90 degrees. Place the parts to be connected later in this device and weld.

This way you can achieve the desired connection angle. For additional convenience, this improvised square is additionally equipped with clamping devices that fix the parts to be joined and prevent the connection angle from being violated due to thermal changes during welding in metal.

The next mandatory element of our press is a removable stop that can move along the guides and transmit pressure from the central working rod of the hydraulic jack to the workpiece. To make it, prepare several pieces of steel strip, which is about 1 centimeter thick. Make the length of the parts less than the resulting distance between the posts. Connect the resulting parts in several places by welding on both sides.

To ensure quick replacement of this part when performing any hydraulic work and to fix the element when moving on vertical posts, it is necessary to drill two through holes in the resulting block of steel strips and saw off two plates; their length should be 100 millimeters longer than the length of the block. Also drill two holes in the plates that match the holes in the block.

When installing the block on the frame of the press using a hydraulic jack, select two bolts of the required length with nuts and washers with your own hands and connect the resulting plates to the block so that they are located on both sides of the racks. If there is a need to achieve less free play of the hydraulic jack piston, the space between the moving stop and the upper beam of the structure can be reduced by additionally installing an intermediate square profile.

To do this, saw off a section of a square profile that has a length that is equal to the distance between the posts, and attach it at an equal distance with the welds. This will significantly reduce the working distance of the hydraulic press and reduce the time spent on certain types of work.

To further reduce the stroke of the working rod of a hydraulic jack, you can use additional replaceable inserts, which are made of solid or hollow steel profiles or replaceable anvils. To create them, you should saw off several parts of different thicknesses and additionally mark them for quick and thorough selection of the desired element.

Hydraulic jack repair

Hydraulic jacks periodically require maintenance, so it is necessary to add liquid to the working cylinder, which flows out during operation through oil seals and various seals. In addition to oil leakage, malfunctions of the jack include jamming when lifting a load to a certain height, the inability to lower the jack after lifting, or the inability to lift even a light load.

Oil leak

To repair and test a hydraulic jack at home, you should buy the necessary repair kit for the equipment. Before performing repairs, you must first disassemble the device. An extension to the keys may be required to provide significant force and greater leverage. Be sure to prepare a container to drain the old oil and prepare new working fluid.

After this, the pistons should be removed and checked for corrosion. All dirt and corrosion are removed. Check to see if the stem is bent. If deformation occurs, then it is unlikely that it will be possible to make it even again and there is no need to repair anything further.

It is necessary to check the oil bypass valve. To do this, the valve is unscrewed and checked for deformation or dirt getting inside the valve. If the valve is faulty due to mechanical deformation, then it should simply be replaced. In addition, it can simply become dirty, and the ball will not fit tightly into its seat. This is the reason for the passage of working fluid.

Completely drain the old oil. This procedure is quite simple, although it takes a lot of time while the oil flows from one cylinder to another. The liquid is drained by pumping the system, moving the lever up and down. Wash all parts thoroughly to remove dirt and oil residues. Completely replace all cuffs and gaskets.

Another reason for the failure of a hydraulic jack may be dirt that has entered the working cavity. To remove it from there, you need to unscrew the head of the housing, pour kerosene into its base and pump the jack with the locking needle unscrewed. Upon completion of the operation, kerosene should be removed and clean oil should be poured into the working cavity.

Air entry

During long-term operation, air bubbles accumulate in the working cavity of the jack, significantly reducing its effectiveness. The reason for this is usually air that has entered the hydraulic system due to a lack of operating oil. You can fix this problem as follows.

First, open the oil tank cap and bypass valve, and then quickly pump the hydraulic press pump several times. In this way, air will be forced out of the working cavity into the oil container. You can then close the bypass valve and the hole leading to the oil tank. If you did everything correctly, the air will be removed and the jack will work normally again.

If your attempt is unsuccessful, repeat all of the above steps. However, this method is not the only one for removing air from the working cavity. It is not difficult to determine the presence of air in the working cavity: the jack does not work at all, or the load is lifted slowly.

First, unscrew the locking needle one and a half to two turns, then lift the plunger by hand by the screw to the uppermost point and release it so that it is again in the lower position. Repeat these steps twice or three times. To prevent a similar problem from arising in the future, it is worth periodically checking the oil level in the hydraulic jack and adding working fluid if it is insufficient.

Thus, you have become familiar with the design of a hydraulic jack, studied its advantages and disadvantages, understood the classification of such equipment and understood how a hydraulic jack works. Now you can start assembling the device yourself. And don’t forget about periodic maintenance and adding operating oil.